Abstract

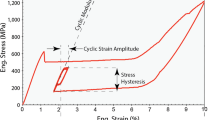

During tensile testing of superelastic Nitinol material, the specimen temperature increases as result of the exothermic Austenite-to-Martensite phase transformation. The increase in specimen temperature has great influence on the stress-strain response—in particular, upper and lower plateau values—and limits the strain rate of the tensile test, so that for larger specimen dimension, the strain rate has to be reduced. A special setup of the tensile testing equipment has been developed using a fan to improve the heat exchange between the specimen and the ambiance to allow much higher strain rates as well as even gradient of the upper and lower plateau. It could be shown that the strain rate of the first loading and unloading cycle could be two to four times higher as recommended in ASTM F 2516-07 without any negative impact on the determined values. The needed time for tensile testing of Nitinol products could be reduced considerably. The improved heat exchange gives a better comparability and reproducibility of the tensile test data.

Similar content being viewed by others

References

ASTM F 2004 Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis.

ASTM F 2005 Terminology for Nickel-Titanium Shape Memory Alloys.

ASTM F 2063 Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants.

ASTM F 2082 Test Method for Determination of Transformation Temperature of Nickel-Titanium Shape Memory Alloys by Bend and Free Recovery.

ASTM F 2516 Test Method for Tension Testing of Nickel-Titanium Superelastic Materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at Shape Memory and Superelastic Technologies 2008, held September 21-25, 2008, in Stresa, Italy, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Johe, R. Tensile Testing of Nitinol Tubes and Wires with Higher Strain Rates. J. of Materi Eng and Perform 18, 836–842 (2009). https://doi.org/10.1007/s11665-009-9406-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-009-9406-x