Abstract

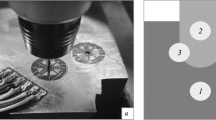

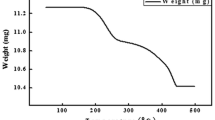

A coupled experimental and theoretical study is reported here on friction hydro-pillar processing of AISI 4140 steel, which is a novel solid-state joining technique to repair and fill crack holes in thick-walled components by an external stud. The stud is rotated and forced to fill a crack hole by plastic flow. During the process, frictional heating occurs along the interface of the stud and the wall of crack hole leading to thermal softening of the stud that eases its plastic deformation. The effect of the stud force, its rotational speed and the total processing time on the rate of heat generation and resulting transient temperature field is therefore examined to correlate the processing variables with the joint structure and properties in a systematic and quantitative manner, which is currently scarce in the published literature. The results show that a gentler stud force rate and greater processing time can promote proper filling of the crack hole and facilitate a defect-free joint between the stud and original component.

Similar content being viewed by others

References

D.L.H. Bulbring., D.G. Hattingh., A. Botes., and D.H. Odendaal: J. S. Afr. Inst. Min. and Metall, 2013, vol. 113, pp. 129–36.

P.J. Hartley: Weld. Met. Fab, 2000, vol. 9, pp. 6–8.

D.G. Hattingh, M.N. James, M. Newy, R. Scheepers, and P. Doubell: Theor. Appl. Fract. Mech, 2016, vol. 83, pp. 125–34.

S. Liu, J.E. Indacochea: Metals Handbook, 10th ed., American society for Metals, Ohio, 1992.

V.H.C. de Albuqueraque, C.C. Silva, C.R.O. Moura, W.M. Aguiar, and J.P. Farias: Mater. Des, 2009, vol. 30, pp. 1068–74.

D.T. Buzzatti, J.T. Buzzatti, R.E. dos Santos, F. Mattei, M. Chludzinski, and T.R. Strohaecker: Soldagem & Inspecao, 2015, vol. 20, pp. 287–99.

D.G. Hattingh, D.L.H. Bulbring, A. Els-Botes, M.N. James: Mater. Des, 2011, vol. 32, pp. 3421–30.

Y. Yin, X. Yang, L. Cui, F. Wang, and S. Li: Mater. Des, 2015, vol. 88, pp. 990–98.

C.P. Meinhardt, M. Chuldzinski, R.F. Ribeiro, C.L.F. Rocha, A.C.S. Santos, and T.R. Strokaeker: J. Mater. Process. Technol, 2017, vol. 246(1), pp. 158–66.

ASM Handbook, Properties and Selection: Irons, Steels, and High-Performance Alloys, vol. 1, ASTM International, 2008, pp. 1–1063.

C.C. Silva, V.H.C. de Albuqueraque, C.R.O. Moura, W.M. Aguiar, and J.P. Farias: J. Mater. Process. Technol. 2009, vol. 18, pp. 324–31.

M. Chludzinski, M.P. Paes, F.L. Bastian, and T.R. Strohaecker, Mater. Des, 2012, vol. 33, pp. 340–44.

A. Meyer: Master’s dissertation, Technical University Brunschweigh, Germany, 2002. https://www.hzg.de/imperia/md/content/hzg/zentrale_einrichtungen/bibliothek/berichte/gkss_berichte_2003/gkss_2003_4pdf, Accessed 03 October, 2017.

B. Vicharapu, L.F. Kanan, T. Clarke, and A. De: Sci. Technol. Weld. Join, 2017. vol. 22, pp. 555–61.

S.J. Unfried, M.T.P. Paes, T.F.C. Hermenegildo, F.L. Bastian, and A.J. Ramirez: Sci. Technol. Weld. Join, 2015, vol. 15, pp. 506–13.

C.R.L. Lessa, D. Martina, A.P. Figueirea, B.F. Machado, F. Claudiam, and T.R. Strohaeker: Materials Research, 2015, vol. 19, pp. 928–36.

L. Cui, X. Yang, D. Wang, X. Hou, J. Cao, and W. Xu: Mater. Sci. Eng. A, 2014, vol. 611, pp. 15–28.

ASTM E230/E230M, ASTM International, 2011, Pennsylvania, USA.

R. Nandan, G.G. Roy, T.J. Lienert, and T. Debroy: Acta. Mater, 2007, vol. 55, pp. 883–95.

V. Buchibabu, G.M. Reddy, and A. De: J. Mater. Process. Technol, 2017, vol. 241, pp. 86–92.

J.C. Ion, K.E. Easterling, and M.F. Ashby, Acta. Metall, 1984, vol. 32, pp. 1949–62.

R.S. Lakhkar, Y.C. Shin, and M.J.M., Krane: Mat. Sci. Eng. A, 2008, vol. 408, pp. 209–17.

ASM Handbook, Steel Heat Treating Fundamentals and Processes, vol. 4, ASTM International, 2013, pp. 1–784.

F. Cordovilla, A. Garcia-Beltran, P. Sanho, J. Domingues, L. Ruiz-de- Lara, J.L. Ocana: Mater. Des, 2016, vol. 102, pp. 225–37.

Acknowledgment

The work was jointly supported by the Department of Science and Technology (Ministry of Science and Technology), India, and National Council for Science and Technological Development (CNPq of the Ministry of Science, Technology and Innovation), Federal Republic of Brazil.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 3, 2017.

Appendix A

Appendix A

The hardness distribution across the joint is estimated using the numerically computed cooling rate and holding time between 1073 and 773 K at any given location and analytical-cum-empirical relations for prediction solid-state phase transformations and consequent hardness for steels of similar compositions available in the published literature.[21] The cooling times to form either 50 pct martensite (ΔtM) or 50 pct bainite (ΔtB) are estimated as

where CEQ is the carbon equivalent and considered as [International Institute of Welding].

The maximum volume fraction (Vmax) undergoing solid-state phase transformations is estimated as a function of peak temperature (TP) and percent of carbon content (C) in steel as

where A1 and A3 are respectively the lower and upper critical temperatures for austenite formation and typically correspond to 1013 and 1293 K, respectively, for AISI 4140 steel. The volume fractions of martensite (VM), bainite (VB) and perlite-ferrtie (VFP) were estimated next as

where ∆t was the total cooling time from 1073 to 773 K. The Vickers hardnesses of different constituent phases were computed as

where (CR) is the computed cooling rate from 1073 K to 773 K. The net hardness (H) at any location is therefore estimated as

A sample calculation is shown in Table A1 for the estimation of hardness from the computed thermal history in FHPP of AISI 4140 steel. The calculations correspond to the thermal cycle shown in Figure 7(c) at a force rate of 4.0 kN/s. Figure A1 shows cooling curves from Figure 7(c) superimposed on a CCT diagram for AISI 4140 steel.[24]

Rights and permissions

About this article

Cite this article

Kanan, L.F., Vicharapu, B., Bueno, A.F.B. et al. Friction Hydro-Pillar Processing of a High Carbon Steel: Joint Structure and Properties. Metall Mater Trans B 49, 699–708 (2018). https://doi.org/10.1007/s11663-018-1171-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1171-5