Abstract

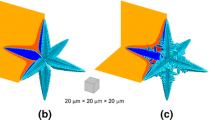

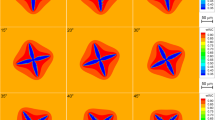

A 3D parallel cellular automaton-finite volume method (CA-FVM) model was used to simulate the equiaxed dendritic growth of an Fe-0.82 wt pct C alloy with xy-in-out and xyz-in-out type forced flows and the columnar dendritic growth with y-in-out type forced flow. In addition, the similarities and differences between the results of the 3D and 2D models are discussed and summarized in detail. The capabilities of the 3D and 2D CA-FVM models to predict the dendritic growth of the alloy with forced flow are validated through comparison with the boundary layer correction and Oseen–Ivanstov models, respectively. Because the forced flow can pass around perpendicular arms of the dendrites, the secondary arms at the sides upstream from the perpendicular arms are more developed than those on the upstream side of the upstream arms, especially at higher inlet velocities. In addition, compared to the xy-in-out case, the growth of the downstream arms is less inhibited and the secondary arms are more developed in the xyz-in-out case because of the greater lateral flow around their tips. Compared to the 3D case, the 2D equiaxed dendrites are more asymmetrical and lack secondary arms because of the thicker solute envelope. In the 3D case, the columnar dendrites on the upstream side (left one) are promoted, while the middle and downstream dendrites are inhibited in sequence. However, the sequential inhibition starts on the upstream side in the 2D case. This is mainly because the melt can pass around the upstream branch in 3D space. However, it can only climb over the upstream tip in 2D space. Additionally, the secondary arms show upstream development, which is more significant with increasing inlet velocity. The level of development of the secondary arms is also affected by the decay of the forced flow in the flow direction.

Similar content being viewed by others

References

E.J. Pickering: ISIJ Int., 2013, vol. 53, pp. 935-949.

W.L. Wang, S. Luo and M.Y. Zhu: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 396-406.

S.Q. Wang, G. Alvarez De Toledo, K. Valimaa and S. Louhenkilpi: ISIJ Int., 2014, vol. 54, pp. 2273-2282.

J.A. Spittle: Int. Mater. Rev., 2006, vol. 51, pp. 247-269.

H.Q. Yu and M.Y. Zhu: Ironmak. Steelmak., 2012, vol. 39, pp. 574-584.

H.B. Sun and J.Q. Zhang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1133-1149.

H.P. Liu, M.G. Xu, S.T. Qiu and H. Zhang: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 1657-1675.

Z.J. Su, J. Chen, K. Nakajima and J.C. He: Steel Res. Int., 2009, vol. 80, pp. 824-833.

H.J. Wu, N. Wei, Y.P. Bao, G.X. Wang, C.P. Xiao and J.J. Liu: Int. J. Miner. Metall. Mater., 2011, vol. 18, pp. 159-164.

H. Yasuda, T. Nagira, M. Yoshiya, N. Nakatsuka, A. Sugiyama, K. Uesugi and K. Umetani: ISIJ Int., 2011, vol. 51, pp. 402-408.

N. Shevchenko, O. Roshchupkina, O. Sokolova and S. Eckert: J. Cryst. Growth, 2015, vol. 417, pp. 1-8.

P. Bouissou and P. Pelcé: Phys. Rev. A, 1989, vol. 40, pp. 6673-6680.

C.A. Gandin, G. Guillemot, B. Appolaire and N.T. Niane: Mater. Sci. Eng. A, 2003, vol. 342, pp. 44-50.

M.F. Zhu and D.M. Stefanescu: Acta Mater., 2007, vol. 55, pp. 1741-1755.

T. Takaki: ISIJ Int., 2014, vol. 54, pp. 437-444.

K. Reuther and M. Rettenmayr: J. Comput. Phys., 2014, vol. 279, pp. 63-66.

J.Z. Zhao, L. Li and X.F. Zhang: Acta Metall. Sin., 2014, vol. 50, pp. 641-651.

M.A. Jaafar, D.R. Rousse, S. Gibout and J.-P. Bédécarrats: Renew. Sust. Energ. Rev., 2017, vol. 74, pp. 1064-1079.

D.M. Li, R. Li and P.W. Zhang: Appl. Math. Model., 2007, vol. 31, pp. 971-982.

M.F. Zhu, T. Dai, S.Y. Lee and C.P. Hong: Comput. Math. Appl., 2008, vol. 55, pp. 1620-1628.

D. Sun, M. Zhu, S. Pan and D. Raabe: Acta Mater., 2009, vol. 57, pp. 1755-1767.

Z.P. Guo, J. Mi, S. Xiong and P.S. Grant: Metall. Mater. Trans. B, 2013, vol. 44, pp. 924-937.

W.L. Wang, S. Luo and M.Y. Zhu: Comput. Mater. Sci., 2014, vol. 95, pp. 136-148.

N. Al-Rawahi and G. Tryggvason: J. Comput. Phys., 2004, vol. 194, pp. 677-696.

Y. Lu, C. Beckermann and J.C. Ramirez: J. Cryst. Growth, 2005, vol. 280, pp. 320-334.

C.C. Chen, Y.L. Tsai and C.W. Lan: Int. J. Heat Mass Transf., 2009, vol. 52, pp. 1158-1166.

L. Yuan and P.D. Lee: Modell. Simul. Mater. Sci. Eng., 2010, vol. 18.

Y.F. Shi, Q.Y. Xu and B.C. Liu: Rare Metal Mat. Eng., 2013, vol. 42, pp. 700-705.

X.F. Zhang and J.Z. Zhao: Acta Metall. Sin., 2012, vol. 48, pp. 615-620.

X.F. Zhang and X.K. Li: Int. J. Mater. Res., 2015, vol. 106, pp. 1053-1059.

W.L. Wang, S. Luo and M.Y. Zhu: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 1355-1366.

X.F. Zhang and J.Z. Zhao: Spec. Cast. Nonferrous Alloys, 2013, vol. 33, pp. 323-327.

Y. Natsume, D. Takahashi, K. Kawashima, E. Tanigawa and K. Ohsasa: ISIJ Int., 2013, vol. 53, pp. 838-847.

W.L. Wang, S. Luo and M.Y. Zhu: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 1339-1354.

W.Q. Tao: Numerical Heat Transfer. 2nd ed., Xi’an Jiao Tong University Press, Xi’an, 2001.

L. Nastac: Acta Mater., 1999, vol. 47, pp. 4253-4262.

S.Y. Pan and M.F. Zhu: Acta Mater., 2010, vol. 58, pp. 340-352.

A. Barbieri and J. S. Langer: Phys. Rev. A, 1989, vol. 39, pp. 5314-5325.

Acknowledgments

The authors sincerely acknowledge the financial support from the National Natural Science Foundation of China Nos. U1560208, 51474058, and 51674072, the Outstanding Talent Cultivation Project of Liaoning Province No. 2014029101, and the Fundamental Research Funds for the Central Universities No. N162410002-16.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 6, 2017.

Rights and permissions

About this article

Cite this article

Wang, W., Wang, Z., Luo, S. et al. Influence of Forced Flow on the Dendritic Growth of Fe-C Alloy: 3D vs 2D Simulation. Metall Mater Trans B 48, 3109–3119 (2017). https://doi.org/10.1007/s11663-017-1102-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1102-x