Abstract

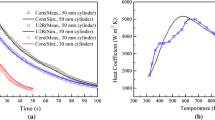

Based on the hardenability of three medium carbon steels, cylinders with the same 60-mm diameter and 240-mm length were designed for quenching in water to obtain microstructures, including a pearlite matrix (Chinese steel mark: 45), a bainite matrix (42CrMo), and a martensite matrix (40CrNiMo). Through the combination of normalized functions describing transformation plasticity (TP), the thermo-elasto-plastic constitutive equation was deduced. The results indicate that the finite element simulation (FES) of the internal stress distribution in the three kinds of hardenable steel cylinders based on the proposed exponent-modified (Ex-Modified) normalized function is more consistent with the X-ray diffraction (XRD) measurements than those based on the normalized functions proposed by Abrassart, Desalos, and Leblond, which is attributed to the fact that the Ex-Modified normalized function better describes the TP kinetics. In addition, there was no significant difference between the calculated and measured stress distributions, even though TP was taken into account for the 45 carbon steel; that is, TP can be ignored in FES. In contrast, in the 42CrMo and 40CrNiMo alloyed steels, the significant effect of TP on the residual stress distributions was demonstrated, meaning that TP must be included in the FES. The rationality of the preceding conclusions was analyzed. The complex quenching stress is a consequence of interactions between the thermal and phase transformation stresses. The separated calculations indicate that the three steels exhibit similar thermal stress distributions for the same water-quenching condition, but different phase transformation stresses between 45 carbon steel and alloyed steels, leading to different distributions of their axial and tangential stresses.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

M. Jung, M. Kang, and Y.K. Lee: Acta Mater., 2012, vol. 60, pp. 525–36.

R. Isomura and H. Sato: J. Jpn. Inst. Met., 1961, vol. 25, pp. 360–64.

H. Scott: Scientific Papers of the Bureau of Standards, 1925, vol. 20, pp. 399–444.

M.G. Moore and W.P. Evans: SAE Trans., 1958, vol. 66, pp. 340–45.

T. Inoue and K. Arimoto: J. Mater. Eng. Performance, 1997, vol. 6, pp. 51–60.

S. Denis, S. Sjöström, and A. Simon: Metall. Trans. A, 1987, vol. 18A, pp. 1203–12.

H.H. Bok, J.W. Choi, D.W. Suh, M.G. Lee, and F. Barlat: Int. J. Plast., 2015, vol. 73, pp. 142–70.

M.G. Lee, S.J. Kim, H.N. Han, and W.C. Jeong: Int. J. Plast., 2009, vol. 25, pp. 1726–58.

E.A. Ariza, M.A. Martorano, N.B. de Lima, and A.P. Tschiptschin: ISIJ Int., 2014, vol. 54, pp. 1396–1405.

L. Taleb, N. Cavallo, and F. Waeckel: Int. J. Plast., 2001, vol. 17, pp. 1–20.

G.W. Greenwood and R.H. Johnson: Proc. R. Soc. London A, 1965, vol. 283, pp. 403–22.

H.N. Han and J.K. Lee: ISIJ Int., 2002, vol. 42, pp. 200–05.

T. Inoue and H. Wakamatsu: Strojarstvo, 2011, vol. 53, pp. 11–18.

S. Denis, E. Gautier, A. Simon, and G. Beck: Mater. Sci. Technol., 1985, vol. 1, pp. 805–14.

K.F. Wang, S. Chandrasekar, and H.T.Y. Yang: J. Manuf. Sci. Eng., 1997, vol. 119, pp. 257–65.

Y. Nagasaka, J.K. Brimacombe, E.B. Hawbolt, I.V. Samarasekera, B. Hernandez-Morales, and S.E. Chidiac: Metall. Trans. A, 1993, vol. 24A, pp. 795–808.

Y. Liu, S. Qin, Q. Hao, N. Chen, X. Zuo, and Y. Rong: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1402–13.

B.L. Ferguson, Z. Li, and A.M. Freborg: Comput. Mater. Sci., 2005, vol. 34, pp. 274–81.

D.Y. Ju, R. Mukai, and T. Sakamaki: Int. Heat Treat. Surf. Eng., 2011, vol. 5, pp. 65–68.

D. Lambert and K. Arimoto: Finite Element Analysis of Internal Stresses in Quenched Steel Cylinders: 19th ASM Heat Treating Society Conf. Proc. Including Steel Heat Treating in the New Millennium, 1999, pp. 425–34.

X.W. Zuo, N.L. Chen, F. Gao, and Y.H. Rong: Int. Heat Treat. Surf. Eng., 2014, vol. 8, pp. 15–23.

Non-Destructive Testing—Test Method for Residual Stress Analysis by X-ray Diffraction, European Standard EN15305, 2008.

J.B. Leblond, G. Mottet, J. Devaux, and J.C. Devaux: Mater. Sci. Technol., 1985, vol. 1, pp. 815–22.

M.G. Lee, S.J Kim, and H.N. Han: Int. J. Plast., 2010, vol. 26, pp. 688–710.

A. Bejan and Allan D. Kraus: Heat Transfer Handbook, Wiley, Hoboken, NJ, 2003, pp. 165–67.

M.E. Kakhki, A. Kermanpur, and M.A. Golozar: Modell. Simul. Mater. Sci. Eng., 2009, vol. 17, p. 045007.

S.J. Lee and Y.K. Lee: Acta Mater., 2008, vol. 56, pp. 1482–90.

S.J. Lee: Adv. Mater. Res., 2013, vols. 798–799, pp. 39–44.

D.P. Koistinen and R.E. Marburger: Acta Metall., 1959, vol. 7, pp. 59–60.

S.M.C. van Bohemen and J. Sietsma: Mater. Sci. Technol., 2009, vol. 25, pp. 1009–12.

J.B. Austin and R.L. Rickett: Trans. Am. Inst. Min. Metall. Eng., 1939, vol. 135, pp. 396–415.

George F. Vander Voort: Atlas of Time-Temperature Diagrams for Irons and Steels, ASM INTERNATIONAL, Materials Park, OH, 1991, p. 140.

J.S. Kirkaldy and D. Venugopalan: in Phase Transformation in Ferrous Alloys, A.R. Marder and J.I. Goldstein, eds., TMS-AIME, Warrendale, PA, 1984, pp. 126–47.

V.E. Scheil: Arch. Eisenhüttenwes., 1935, vol. 12, pp. 565–67.

F.D. Fischer, G. Reisner, E. Werner, K. Tanaka, G. Cailletaud, and T. Antretter: Int. J. Plast., 2000, vol. 16, pp. 723–48.

F.D. Fischer, Q.P. Sun, and K. Tanaka: Appl. Mech. Rev., 1996, vol. 49, pp. 317–64.

C.C. Liu, K.F. Yao, X.J. Xu, and Z. Liu: Mater. Sci. Technol., 2001, vol. 17, pp. 983–88.

G.T. Houlsby and A.M. Puzrin: Principles of Hyperplasticity, Springer, London, 2007, pp. 13–33.

S. Petit-Grostabussiat, L. Taleb, and J.F. Jullien: Int. J. Plast., 2004, vol. 20, pp. 1371–86.

J.B. Leblond, G. Mottet, and J.C. Devaux: J. Mech. Phys. Solids, 1986, vol. 34, pp. 411–32.

R. Schröder: Mater. Sci. Technol., 1985, vol. 1, pp. 754–64.

K.O. Lee, J.M. Kim, M.H. Chin, and S.S. Kang: J. Mater. Process. Technol., 2007, vol. 182, pp. 65–72.

H.S. Yu: Plasticity and Geotechnics, Springer, Boston, MA, 2006, pp. 492–93.

X. Luo and G.E. Totten: J. ASTM Int., 2011, vol. 8, p. JAI103397.

M. Narazaki, G.E. Totten, and G.M. Webster: in Handbook of Residual Stress and Deformation of Steel, G.E. Totten, M. Howes, and T. Inoue, eds., Materials Park, OH, 2002, pp. 248–95.

Acknowledgment

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51371117 and 51401121).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 12, 2017.

Rights and permissions

About this article

Cite this article

Liu, Y., Qin, S., Zhang, J. et al. Influence of Transformation Plasticity on the Distribution of Internal Stress in Three Water-Quenched Cylinders. Metall Mater Trans A 48, 4943–4956 (2017). https://doi.org/10.1007/s11661-017-4230-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4230-7