Abstract

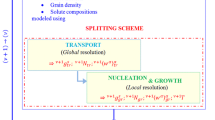

A deterministic multigrain and multiphase model of equiaxed solidification of binary alloys is proposed, implemented, and analyzed. An important feature of the present model is the creation of classes of dendritic and globulitic grains according to their instantaneous sizes during solidification. Globulitic and dendritic grain growth, coarsening of secondary dendrite arms, distribution of nucleation undercoolings, and equiaxed eutectic growth are consistently included in the model equations. Important model assumptions are uniform temperature, negligible liquid convection, and negligible grain movement. Calculated cooling curves, solid fraction evolution, average grain sizes, and eutectic fractions agree well with predictions of previous models for dendritic and globulitic equiaxed grains. Predicted grain sizes decrease with an increase in cooling rate for an Al-2.12 pct Cu alloy and with an increase in Si concentration up to 3 pct for Al-Si alloys, agreeing quantitatively with experimental results. Simulations for an Al-7 pct Si alloy predict that an increase in grain size correlates with an increase in the magnitude of the recalescence observed in cooling curves. These calculations agree well with experimental results when the transition from a globulitic to a dendritic morphology occurs in the model before the minimum temperature of recalescence is reached.

Similar content being viewed by others

Abbreviations

- A :

-

Area of interface (m2) or constant of coarsening law (m s−a)

- A 0 :

-

Area of REV boundary (m2)

- A e :

-

Constant of eutectic growth law (m s−1 K−2)

- a :

-

Constant of coarsening law

- b :

-

Boundary of REV

- C :

-

Mass fraction of solute (–)

- \( \bar{C} \) :

-

Surface average of solute mass fraction (–)

- C 0 :

-

Initial solute mass fraction (–)

- \( \left\langle {C_{di} } \right\rangle^{di} \) :

-

Average of solute mass fraction in interdendritic liquid of grains in class i (–)

- C l :

-

Mass fraction of solute in the external liquid (–)

- C ∞ l :

-

Mass fraction of solute in bulk liquid (–)

- \( \left\langle {C_{l} } \right\rangle^{l} \) :

-

Average of solute mass fraction in external liquid (–)

- C liq :

-

Solute mass fraction of the liquidus line (–)

- C liq,gi :

-

Solute mass fraction of the liquidus line for globulitic grains of class i (–)

- c p :

-

Volumetric specific heat (J m−3 K−1)

- \( \left\langle {C_{si} } \right\rangle^{si} \) :

-

Average of solute mass fraction in the solid of grains in class i (–)

- die :

-

Interface between eutectic and interdendritic liquid in grains of class i

- D :

-

Coefficient of solute diffusion (m2 s−1)

- erfc :

-

Complementary error function

- I −1 V :

-

Inverse of the Ivantsov function

- \( \vec{j}_{k} \) :

-

Diffusive flux of solute (kg m−2 s−1)

- k, j :

-

Constituents of the multiphase model

- K :

-

Solute partition coefficient (–)

- \( \bar{l} \) :

-

Final average grain size (m)

- L :

-

Volumetric latent heat (J m−3)

- m l :

-

Slope of the liquidus line (K pct mass−1)

- n :

-

Total number density of grains of primary solid (m−3)

- \( \vec{n}_{k} \) :

-

Normal unit vector at the interfaces of k and pointing out of V k (–)

- n e :

-

Number density of eutectic cells (m−3)

- n ext e :

-

Extended number density of eutectic cells (m−3)

- n i :

-

Number density of grains in class i (m−3)

- n ext i :

-

Extended number density of grain nuclei in class i (m−3)

- n T :

-

Total number density of substrate particles for heterogeneous nucleation (m−3)

- N :

-

Number of existing grain classes

- N max :

-

Maximum number of possible grain classes

- Pe i :

-

Peclet number for grains in class i (–)

- Q :

-

Average heat flux out of REV (J m−2 s−1)

- r :

-

Radial coordinate (m)

- \( \dot{R} \) :

-

Cooling rate of the liquid before solidification (K s−1)

- REV:

-

Representative elementary volume

- R ext e :

-

Extended radius of eutectic cells (m)

- R fi :

-

Radius of spherical unit cell for grains in class i (m)

- R i :

-

Radius of grain envelopes in class i (m)

- R ext i :

-

Extended radius of grains in class i (m)

- S :

-

Concentration of interfacial area (m−1)

- t :

-

Time (s)

- t ne :

-

Time of eutectic nucleation (s)

- t ni :

-

Time of nucleation of grains in class i (s)

- T :

-

Temperature (K)

- T 0 :

-

Initial temperature (K)

- T e :

-

Eutectic temperature (K)

- T f :

-

Melting point of the pure metal (K)

- V 0 :

-

Volume of the REV (m3)

- V k :

-

Volume of constituent k (m3)

- \( \bar{w} \) :

-

Average normal interface velocity (m s−1)

- \( \vec{w}_{k} \) :

-

Velocity vector of an interface of constituent k (m s−1)

- δ :

-

Thickness of effective diffusion layer (m)

- Γ:

-

Gibbs–Thomson coefficient (m K)

- Δt :

-

Time step of the numerical method (s)

- ΔT :

-

Undercooling of the external liquid (K)

- ΔT ne :

-

Undercooling for nucleation of eutectic cells (K)

- ΔT ni :

-

Undercooling for nucleation of the grains in class i (K)

- ΔT nucl :

-

Undercooling range for nucleation of the primary phase (K)

- \( \overline{{\Delta T_{N} }} \) :

-

Average nucleation undercooling (K)

- ΔT σ :

-

Standard deviation of the nucleation undercooling distribution (K)

- ɛ :

-

Volume fraction (–)

- λ i :

-

Average spacing between secondary dendrite arms in grains of class i (m)

- λ i0 :

-

Initial spacing between secondary dendrite arms in grains of class i (m)

- ρ :

-

Mass density (kg m−3)

- σ ϕ :

-

Standard deviation of particle size distribution (–)

- ϕ 0 :

-

Geometrical mean diameter of particle size distribution (μm)

- ψ k :

-

General field variable defined in constituent k

- Ω :

-

Dimensionless undercooling (–)

- di :

-

Interdendritic liquid of grains in class i

- e :

-

Eutectic

- ee :

-

External eutectic

- gi :

-

Grains of class i

- i :

-

Index of a grain class

- l :

-

External liquid

- ldi :

-

Interface between external liquid and interdendritic liquid of grains in class i

- le :

-

Interface between external liquid and eutectic

- li :

-

Interface between external liquid and grain envelopes of class i

- lsi :

-

Interface between external liquid and the solid of grains in class i

- sdi :

-

Interface between interdendritic liquid and solid of grains in class i

- s :

-

Primary solid

- si :

-

Primary solid of grains in class i

References

W. Oldfield: ASM Trans. Q., 1966, vol. 59, pp. 945–61.

M. Rappaz, P. Thévoz, Z. Jie, J.P. Gabathuler, and H. Lindscheid: in State of the Art of Computer Simulation of Casting and Solidification Processes, H. Fredriksson ed., Les Éditions de Physique, 1986, pp. 277–84.

I. Maxwell and A. Hellawell: Acta Metall., 1975, vol. 23, pp. 229–37.

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans, and D.J. Bristow: Acta Mater., 2000, vol. 48, pp. 2823–35.

M. Rappaz and P. Thevoz: Acta Metall., 1987, vol. 35, pp. 1487–97.

M. Rappaz and P. Thevoz: Acta Metall., 1987, vol. 35, pp. 2929–33.

P. Thevoz, J.L. Desbiolles, and M. Rappaz: Metall. Trans. A, 1989, vol. 20, pp. 311–22.

Z. Kolenda, J. Donizak, and J.C.E. Bocardo: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 505–13.

C.Y. Wang and C. Beckermann: Metall. Trans. A, 1993, vol. 24A, pp. 2787–2802.

C.Y. Wang and C. Beckermann: Mater. Sci. Eng. A, 1993, vol. 171, pp. 199–211.

C. Gandin, S. Mosbah, T. Volkmann, and D. Herlach: Acta Mater., 2008, vol. 56, pp. 3023–35.

M. Wu and A. Ludwig: Acta Mater., 2009, vol. 57, pp. 5621–31.

A.K. Dahle, K. Nogita, J.W. Zindel, S.D. McDonald, and L.M. Hogan: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 949–60.

S. Nafisi, R. Ghomashchi, and H. Vali: Mater. Charact., 2008, vol. 59, pp. 1466–73.

S.D. McDonald, A.K. Dahle, J.A. Taylor, and D.H. StJohn: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1829–37.

S.D. McDonald, K. Nogita, and A.K. Dahle: Acta Mater., 2004, vol. 52, pp. 4273–80.

T.W. Clyne: Mater. Sci. Eng., 1984, vol. 65, pp. 111–24.

D.D. Goettsch and J.A. Dantzig: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1063–79.

J.C. Slattery: Advanced Transport Phenomena, Cambridge University Press, Cambridge, UK, 1999, pp. 585–86.

W.W. Mullins and R.F. Sekerka: J. Appl. Phys., 1963, vol. 34, pp. 323–29.

M. Qian: Acta Mater., 2006, vol. 54, pp. 2241–52.

M.A. Martorano, C. Beckermann, and C.A. Gandin: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1657–74.

J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57–63.

T.Z. Kattamis, J.C. Coughlin, and M.C. Flemings: Trans. AIME, 1967, vol. 239, pp. 1504–11.

H.B. Aaron, D. Fainstei, and G.R. Kotler: J. Appl. Phys., 1970, vol. 41, pp. 4404–10.

J.W. Christian: The Theory of Transformation in Metals and Alloys, Pergamon, New York, NY, 2002, pp. 16–22.

T.E. Quested and A.L. Greer: Acta Mater., 2004, vol. 52, pp. 3859–68.

M.C. Flemings: Mater. Trans., 2005, vol. 46, pp. 895–900.

D. Eskin, Q. Du, D. Ruvalcaba, and L. Katgerman: Mater. Sci. Eng. A, 2005, vol. 405, pp. 1–10.

P. Thévoz, J.L. Desbiolles, and M. Rappaz: Metall. Trans. A, 1989, vol. 20A, pp. 311–22.

C.A. Gandin and M. Rappaz: Acta Metall. Mater., 1994, vol. 42, pp. 2233–46.

Y. Du, Y.A. Chang, B.Y. Huang, W.P. Gong, Z.P. Jin, H.H. Xu, Z.H. Yuan, Y. Liu, Y.H. He, and F.Y. Xie: Mater. Sci. Eng. A, 2003, vol. 363, pp. 140–51.

S.I. Fujikawa, K.I. Hirano, and Y. Fukushima: Metall. Trans. A, 1978, vol. 9A, pp. 1811–15.

C.A. Gandin: Acta Mater., 2000, vol. 48, pp. 2483–2501.

P. Magnin, J.T. Mason, and R. Trivedi: Acta Metall. Mater., 1991, vol. 39, pp. 469–80.

M. Bamberger, B.Z. Weiss, and M.M. Stupel: Mater. Sci. Technol., 1987, vol. 3, pp. 49–56.

J.A. Sarreal and G.J. Abbaschian: Metall. Trans. A, 1986, vol. 17A, pp. 2063–73.

M. Johnsson: Thermochim. Acta, 1995, vol. 256, pp. 107–21.

L.A. Tarshis, J.L. Walker, and J.W. Rutter: Metall. Trans., 1971, vol. 2, pp. 2589–97.

M. Easton and D. StJohn: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1613–23.

J.A. Spittle: Int. J. Cast. Met. Res., 2006, vol. 19, pp. 210–22.

D. Apelian, G.K. Sigworth, and K.R. Whaler: Trans. AFS, 1984, vol. 92, pp. 297–307.

J. Ni and C. Beckermann: Metall. Trans. B, 1991, vol. 22B, pp. 349–61.

S. Whitaker: Chem. Eng. Sci., 1973, vol. 28, pp. 139–47.

W.G. Gray: Chem. Eng. Sci., 1975, vol. 30, pp. 229–33.

Acknowledgments

The authors thank the financial support from FAPESP (03/08576-7) and CNPq (475451/04-0).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 6, 2014.

Appendix

Appendix

1.1 Macroscopic Conservation Equations

The general transport theorem[19] applied to the volume V k of constituent k within a REV of constant volume V 0 can be written as

where ψ k is a field variable defined in constituent k; A kj is the total interfacial area between constituent k and all adjacent constituents within V 0; A kb is the boundary area formed by the REV boundary cutting through constituent k; \( \vec{w}_{k} \) is the velocity of all interfaces and boundaries of k, being zero for its boundaries coinciding with the REV boundary (A kb ), which is motionless; \( \vec{n}_{k} \) is a normal unit vector at the interfaces of k and pointing out of V k .

For ψ k = ρ, which is the mass density and is assumed constant and equal for all constituents, Eq. [A1] gives

For \( \psi_{k} = \rho {\kern 1pt} C_{k}, \)where C k is the mass fraction of solute in constituent k, the species conservation equation in differential form, namely \( \partial \left( {\rho C_{k} } \right)/\partial t = - \vec{\nabla } \cdot \vec{j}_{k} \) (where \( \vec{j}_{k} \) is the diffusive flux of solute), can be substituted on the right-hand side of Eq. [A1]. After application of Gauss theorem and consideration that no solute flows through the REV boundary, the equation becomes

Some of the surface integrals in these equations can be simplified by the following two approximations[43–45]

where \( \bar{w}_{kj} \) is the average normal interface velocity; S kj = A kj /V 0 is an interfacial area concentration; \( \bar{C}_{k} \) and δ k are, respectively, the surface average solute concentration and the effective diffusion length in constituent k at the interface between constituents k and j; and D k is the diffusion coefficient of solute in k. In the absence of convection, the following two integrated jump condition can be used[19]

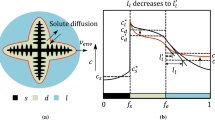

1.2 Development of the Main Equations

The general equations developed in the previous section were applied to the primary solid (si) and interdendritic liquid (di) of all grains belonging to an arbitrary class i and also to the eutectic (e) and external liquid (l), shown in Figure 1. Since the constituents si and di are defined for each of the N classes, there can be at most 2N + 2 different constituents in the model. As shown in Figure 1, the possible interfacial areas between each pair of constituents are A le , A sdi , A ldi , A lsi , A die , and A sie , where subscripts indicate the interface between constituents.

1.2.1 Mass Conservation

Equation [A2] could be applied to the eutectic (k = e), although there are dividing surfaces of discontinuities (interfaces between the solid phases) inside it, because ρ is constant. When \( A_{kj} = A_{le} + \sum\nolimits_{i = 1}^{N} {\left( {A_{sie} + A_{die} } \right)} \), \( \vec{w}_{e} = 0 \) on A sie , and Eq. [A4] is substituted, Eq. [A2] becomes

where S die = A die /V 0 and S le = A le /V 0. The volume fraction of the external eutectic (ɛ ee ), i.e., the eutectic formed in the external liquid is calculated from

Application of Eq. [A2] to the primary solid (k = si) implies \( A_{kj} = A_{sdi} + A_{lsi} \) and gives the following important equation

Equation [A2] was applied to the interdendritic liquid (\( k = d{\kern 1pt} i \)) using \( A_{kj} = A_{sdi} + A_{ldi} \) and added to Eq. [A10], canceling the integral over A sdi owing to Eq. [A6]. The simplification given by Eq. [A4] is also used giving

where ɛ gi = ɛ di + ɛ si , which is the volume fraction of all grains in class i, before the eutectic reaction occurs; S ldi = A ldi /V 0; and S lsi = A lsi /V 0.

For the external liquid (l), the following constitutive relation is valid

1.3 Species Conservation

Local thermodynamic equilibrium is assumed at the solid–liquid interface, implying that C si = KC di at A sdi (dendritic grains) and that C si = KC l at A lsi (globulitic grains), where K is the solute partition coefficient. Also C di or C l adjacent to solid–liquid interfaces can be related to T using the liquidus line, indicated for dendritic grains as C di = C liq(T) and for globulitic grains as C l = C liq,gi (T, R ext i ), where R ext i is the radius of curvature of the globulitic grains in class i (Section II–C–2). Equation [A3] was applied to the primary solid (k = si) adopting \( A_{kj} = A_{sdi} + A_{lsi} \), giving

Substituting Eq. [A5], considering the local thermodynamic equilibrium and noting that C liq and C liq,gi are uniform within the REV give

The integral over A sdi is replaced with Eq. [A10] and all integrals over A lsi are simplified using Eq. [A4] to give

Equation [A3] is applied to the interdendritic liquid (\( k = d{\kern 1pt} i \)), considering \( A_{kj} = A_{sdi} + A_{ldi} \) and substituting Eq. [A7]. Owing to local equilibrium and uniformity of the interdendritic liquid composition, \( C_{l} = C_{\text{liq}} \) at A ldi , the equation becomes

Substituting again Eq. [A5] and noting that C liq is uniform in A sdi and A ldi gives

In the integral over A ldi , \( \vec{n}_{l} = - \vec{n}_{di} \), \( \vec{w}_{l} = \vec{w}_{di} \), and Eq. [A11] is substituted. The integral over A sdi is again replaced with Eq. [A10], forcing the integral on A lsi to appear, which is finally approximated by Eq. [A4], resulting in

Considering \( \varepsilon_{{d{\kern 1pt} i}} = \varepsilon_{gi} - \varepsilon_{si} \) and 〈C di 〉di = C liq, after some arrangement the final equation is

Equation [A3] is applied to the external liquid (l), implying that the surface integrals are done over A ldi and A lsi of all N grain classes. Also C l = C liq at A ldi , and C l = C liq,gi at A lsi , giving

As before, C liq and C liq,gi are taken out of the integral sign, \( \vec{w}_{l} = \vec{w}_{di} \) and \( \vec{n}_{l} = - \vec{n}_{di} \) are substituted in the integral over A ldi , while \( \vec{w}_{l} = \vec{w}_{si} \) and \( \vec{n}_{l} = - \vec{n}_{si} \) are substituted in the integral over A lsi . Also, substituting Eq. [A5] gives

The integrals over A ldi and A lsi are approximated by Eqs. [A11] and [A4], and \( \sum\nolimits_{i = 1}^{N} {{\text{d}}\varepsilon_{gi} /{\text{d}}t = - {\text{d}}\varepsilon_{l} /{\text{d}}t} \) (valid before the eutectic) is used, giving the final equation

Rights and permissions

About this article

Cite this article

Martorano, M.A., Aguiar, D.T. & Arango, J.M.R. Multigrain and Multiphase Mathematical Model for Equiaxed Solidification. Metall Mater Trans A 46, 377–395 (2015). https://doi.org/10.1007/s11661-014-2620-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2620-7