Abstract

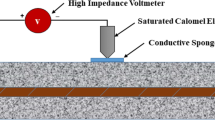

An electro-deposition method has been recently proposed to repair cracked reinforced concrete. To evaluate the corrosion resistance of the reinforcing steel in cracked concrete, three different parameters including type of auxiliary electrode, electrode distance, and current density were studied. Tafel polarization curve was used to evaluate the corrosion resistance of the steel. Self-corrosion potential and corrosion current of the steel were tested. The results indicate that the corrosion resistance improvement of the reinforcing steel is optimal as prism titanium mesh is applied as auxiliary electrode, followed by the flaky titanium mesh and the column titanium bar. When the electrode distance is 60 mm, the corrosion resistance improvement of the reinforcing steel is optimal, and with 80 mm electrode distance, the corrosion resistance improvement is the poorest. The property falls in between them when 40 mm electrode distance is used. Moreover, the corrosion resistance improvement of the reinforcing steel increases as the current density goes up.

Similar content being viewed by others

References

Tang S, Yao Y, Andrade C, et al. Recent Durability Studies on Concrete Structure[J]. Cem. Concr. Res., 2015, 78(12): 143–154

Kessy J G, Alexander M G, Beushausen H. Concrete Durability Standards: International Trends and the South African Context[J]. J. S. Afr. Inst. Civ. Eng., 2015, 57(1): 47–58

Khan I, Francois R, Castel A. Prediction of Reinforcement Corrosion Using Corrosion Induced Cracks Width in Corroded Reinforced Concrete Beams[J]. Cem. Concr. Res., 2014, 56(2): 84–96

James M N, Hattingh D G. Case Studies in Marine Concentrated Corrosion[J]. Eng. Fail. Anal., 2015, 47(1): 1–15

Liu R, Jiang L, Huang G, et al. The Effect of Carbonate and Sulfate Ions on Chloride Threshold Level of Reinforcement Corrosion in Mortar with/without Fly Ash[J]. Constr. Build. Mater., 2016, 113(6): 90–95

Michel A, Pease B J, Peterová A, et al. Penetration of Corrosion Products and Corrosion-Induced Cracking in Reinforced Cementitious Materials: Experimental Investigations and Numerical Simulations[J]. Cem. Concr. Compos., 2014, 47(3): 75–86

Jafferji H, Sakulich A R, Schiffman J D. Preliminary Study on Mitigating Steel Reinforcement Corrosion with Bioactive Agent [J]. Cem. Concr. Res., 2016, 69(5): 9–17

Alghamdi S A, Ahmad S. Service Life Prediction of RC Structures Based on Correlation between Electrochemical and Gravimetric Reinforcement Corrosion Rates[J]. Cem. Concr. Compos., 2014, 47(3): 64–68

Kim H R, Choi W C, Yoon S C, et al. Evaluation of Bond Properties of Reinforced Concrete with Corroded Reinforcement by Uniaxial Tension Testing[J]. Int. J. Concr. Struct. Mater., 2016, 10(3): 43–52

Maruthapandian V, Muralidharan S, Saraswathy V. Spinel NiFe2O4 Based Solid State Embeddable Reference Electrode for Corrosion Monitoring of Reinforced Concrete Structures[J]. Constr. Build. Mater., 2016, 107(3): 28–37

Jin M, Jiang L, Bai S, et al. Research on the Influence of Distance between the Improved Ag/AgCl RE and the Steel on the Corrosion Evaluation in Concrete[J]. Int. J. Electrochem. Sci., 2016, 11(8): 7980–79080

Liu M, Cheng X, Li X, et al. Effect of Carbonation on the Electrochemical Behavior of Corrosion Resistance Low Alloy Steel Rebars in Cement Extract Solution[J]. Constr. Build. Mater., 2017, 130(1): 193–201

Yang L, Xu Y, Zhu Y, et al. Evaluation of Interaction Effect of Sulfate and Chloride Ions on Reinforcements in Simulated Marine Environment Using Electrochemical Methods[J]. Int. J. Electrochem. Sci., 2016, 11(7): 6 943–6 958

Feng H, Cui L, Zhang M. Steel Corrosion Behavior Measurement Based on Electrochemical Approach[J]. Int. J. Electrochem. Sci., 2016, 11(5): 4 658–4 666

Jin M, Xu J, Jiang L, et al. Electrochemical Characterization of a Solid Embeddable Ag/AgCl Reference Electrode for Corrosion Monitoring in Reinforced Concrete[J]. Electrochem., 2014, 82(12): 1 040–1 046

Jin M, Jiang L, Xu J, et al. Electrochemical Characterization of Solid Ag/AgCl Reference Electrode with Different Electrolytes for Corrosion Monitoring of Steel in Concrete[J]. Electrochem., 2016, 84(6): 383–389

Otsuki N, Ryou J S. Use of Electrodeposition for Repair of Concrete with Shrinkage Cracks[J]. Mater. Civ. Eng., 2001, 13(2): 136–142

Chu H, Jiang L, Xiong C, et al. Use of Electrochemical Method for Repair of Concrete Cracks[J]. Constr. Build. Mater., 2014, 73: 58–66

Chu H, Jiang L, You L, et al. Infuence of Mineral Admixtures on the Electro-Deposition Healing Effect of Concrete Cracks[J]. J. Wuhan Univ. Technology-Mater. Sci. Ed., 2014, 29(6): 1 219–1 224

Ryou J S, Otsuki N. Crack Closure of Reinforced Concrete by Electrodeposition Technique[J]. Cem. Concr. Res., 2002, 32(1): 159–164

Ryou J S, Monteiro P. Electrodeposition as a Rehabilitation Method for Concrete Materials[J]. Can. J. Civ. Eng., 2004, 31(5): 776–781

Ryou J S, Otsuki N. Experimental Study on Repair of Concrete Structural Members by Electrochemical Method[J]. Scripta Materialia, 2005, 52: 1 123–1 127

Chu H, Jiang L, Huang X. Study on Carbonation of Concrete after Eletrodeposition[J]. Mater. Rev., 2006, 20(4): 145–147 (in Chinese)

Chu H, Wang P, Jiang L. Advances in Research on Electrodeposition Method for Repair of Concrete Cracks[J]. Mater. Rev., 2010, 24(11): 120–123 (in Chinese)

Chu H, Jiang L, Hua W. Influence of Accessorial Electrode and Distance on Electrodeposition Effect[J]. J. Build. Mater., 2005, 8(4): 456–461(In Chinese)

Huang T, Huang X, Wu P. Review of Recent Developments of Electrochemical Chloride Extraction on Reinforced Concrete in Civil Engi-neering[J]. Int. J. Electrochem. Sci., 2014, 9(5): 4 589–4 597

Polder R B, Walker R J, Page C L. Electrochemical Desalination of Cores from a Reinforced Concrete Coastal Structure[J]. Mag. Concr. Res., 1995, 49(173): 321–327

Ihekwaba N M, Hope B B, C M Hanssont. Pull-out and Bond Degradation of Steel Rebars in ECE Concrete[J]. Cem. Concr. Res., 1996, 26(2): 267–282

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (Nos.51778209, 51609075), and the National Key R&D Program of China (No. 2016YFC0401804)

Rights and permissions

About this article

Cite this article

Chu, H., Pan, C., Xiong, C. et al. Corrosion Resistance of Steel in Cracked Reinforced Concrete after Electro-depositon Treatment. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 1127–1135 (2019). https://doi.org/10.1007/s11595-019-2169-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2169-9