Abstract

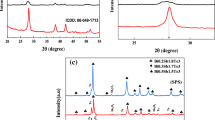

Bi0.5Sb1.5Te3/Cu core/shell powders were prepared by electroless plating and hydrogen reduction, and then sintered into bulk by spark plasma sintering. After electroless plating, with increasing the Cu content, the electrical conductivity keeps enhancing significantly. The highest electrical conductivity reaches 3341S/cm at room temperature in Bi0.5Sb1.5Te3 with 0.67wt% Cu bulk sample. Moreover, the lowest lattice thermal conductivity reaches 0.32 W/m·K at 572.2 K in Bi0.5Sb1.5Te3 with 0.67wt% Cu bulk sample, which is caused by the scattering of the rich-copper particles with different dimensions and massive grain boundaries. According to the results, the ZT values of all Bi0.5Sb1.5Te3/Cu bulk samples have improved in a high temperature range. In Bi0.5Sb1.5Te3 with 0.15wt% Cu bulk sample, the highest ZT value at 573.4 K is 0.81. When the Cu content increases to 0.67wt%, the highest ZT value reaches 0.85 at 622.2 K. Meanwhile, the microhardness increases with increasing the Cu content.

Similar content being viewed by others

References

Rowe DM. CRC Handbook oft Termoelectrics[M]. CRC Press, 1995.

Goldsmid H. Thermoelectric Refrigeration[M]. Springer, 2013

Hsu KF, Loo S, Guo F, et al. Cubic AgPbmSbTe2+m: Bulk Thermoelectric materials with High Figure of Merit[J]. Science, 2004, 303(5659): 818–821

Liu Y, Xu W, Liu DB, et al. Enhanced Thermoelectric Properties of Ga-doped In2O3 Ceramics Via Synergistic Band Gap Engineering and Phonon Suppression[J]. Physical Chemistry Chemical Physics, 2015, 17(17): 11229–11233

He Z, Stiewe C, Platzek D, et al. Effect of Ceramic Dispersion on Thermoelectric Properties of Nano ZrO2/CoSb3 Composites[J]. Journal of Applied Physics, 2007, 101(4): 043707

Alam H, Ramakrishna S. A Review on the Enhancement of Figure of Merit from Bulk to Nano-Thermoelectric Materials[J]. Nano Energy, 2013, 2(2): 190–212

Fu N, Sun L, Liang S, et al. Enhanced Thermoelectric Power Factor of Bi2Sr2CO2Oy Thin Films by Incorporating Au Nanoparticles[J]. Materials & Design, 2016, 89: 791–794

Cappelli E, Bellucci A, Medici L, et al. Nano-crystalline Ag-PbTe Thermoelectric Thin Films by a Multi-Target PLD system[J]. Applied Surface Science, 2015, 336: 283–289

Slack GA, Hussain MA. The Maximum Possible Conversion Efficiency of Silicon-Germanium Thermoelectric Generators[J]. Journal of Applied Physics, 1991, 70(5): 2694–2718

Chung DY, Hogan T, Brazis P, et al. CsBi4Te6: A High-Performance Thermoelectric Material for Llow-Temperature Applications[J]. Science, 2000, 287(5455): 1024–1027

Goldsmid HJ. Bismuth Telluride and Its Alloys as Materials for Thermoelectric Generation[J]. Materials, 2014, 7(4): 2577–2592

Zhao LD, Zhang BP, Li JF, et al. Enhanced Thermoelectric and Mechanical Properties in Textured n-type Bi2Te3 Prepared by Spark Plasma Sintering[J]. Solid State Sciences, 2008, 10(5): 651–658

Greenaway DL, Harbeke G. Band Structure of Bismuth Telluride, Bismuth Selenide and Their Respective Alloys[J]. Journal of Physics and Chemistry of Solids, 1965, 26(10): 1585–1604

Fan FJ, Yu B, Wang YX, et al. Colloidal Synthesis of Cu2CdSnSe4 Nanocrystals and Hot-Pressing to Enhance the Tthermoelectric Figure-of-Merit[J]. Journal of the American Chemical Society, 2011, 133(40): 15910–15913

Lee PY, Chen TC, Huang JY, et al. Enhancement of the Thermoelectric Performance in Nano-/Micro-Structured p-type Bi0.4Sb1.6Te3 Fabricated by Mechanical Alloying and Vacuum Hot Pressing[J]. Journal of Alloys and Compounds, 2014, 615: S476–S481

Sakamoto T, Iida T, Matsumoto A, et al. Thermoelectric Characteristics of a Commercialized Mg2Si Source Doped with Al, Bi, Ag, and Cu[J], Journal of Electronic Materials, 2010, 39(9): 1708–1713

Fan XA, Yang JY, Zhu W, et al. Microstructure and Thermoelectric Properties of n-type Bi2Te2.85Se0.15 Prepared by Mechanical Alloying and Plasma Activated Sintering[J]. Journal of Alloys and Compounds, 2006, 420(1): 256–259

Fan J, Liu H, Shi X, et al. Investigation of Thermoelectric Properties of Cu2GaxSn1-xSe3 Diamond-Like Compounds by Hot Pressing and Spark Plasma Sintering[J]. Acta Materialia, 2013, 61(11): 4297–4304

Wan S, Huang X, Qiu P, et al. The Effect of Short Carbon Fibers on the Tthermoelectric and Mechanical Properties of p-type CeFe4Sb12 Skutterudite Composites[J]. Materials & Design, 2015, 67: 379–384

Shelimova LE, Karpinskii OG, Konstantinov PP, et al. Thermoelectric Properties of the Layered Compound GeBi4Te7 Doped with Copper[J]. Inorganic Materials, 2002, 38(8): 790–794

Liu WS, Zhang Q, Lan Y, et al. Thermoelectric Property Studies on Cu-Doped n-type CuxBi2Te2.7Se0.3 Nanocomposites[J]. Advanced Energy Materials, 2011, 1(4): 577–587

Luo L, Wu Y, Li J, et al. Preparation of Nickel-Coated Tungsten Carbide Powders by room Temperature Ultrasonic-Assisted Electroless Plating[J]. Surface and Coatings Technology, 2011, 206(6): 1091–1095

Lotgering FK. Topotactical Reactions with Ferrimagnetic Oxides Having Hexagonal Crystal Structures-I[J]. Journal of Inorganic and Nuclear Chemistry, 1959, 9(2): 113–123

Zhao LD, Zhang BP, Liu WS, et al. Effect of Mixed Grain Sizes on Thermoelectric Performance of Bi2Te3 Compound[J]. Journal of Applied Physics, 2009, 105(2): 023704

Huang Z, Dai X, Yu Y, et al. Enhanced Thermoelectric Properties of p-type Bi0.5Sb1.5Te3 bulk alloys by Electroless Plating with Cu and Annealing[J]. Scripta Materialia, 2016, 118: 19–23

Liu XJ, Wang CP, Ohnuma I, et al. Thermodynamic Assessment of the Phase Diagrams of The Cu-Sb and Sb-Zn Systems[J]. Journal of Phase Equilibria, 2000, 21(5): 432–442

Tang X, Xie W, Li H, et al. Preparation and Thermoelectric Transport Properties of High-Performance p-type Bi2Te3 with Layered Nanostructure[J]. Applied Physics Letters, 2007, 90(1): 12102–12102

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No. 51371073)

Rights and permissions

About this article

Cite this article

Dai, X., Huang, Z., Yu, Y. et al. Effects of Electroless Plating with Cu Content on Thermoelectric and Mechanical Properties of p-type Bi0.5Sb1.5Te3 Bulk Alloys. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 33, 797–801 (2018). https://doi.org/10.1007/s11595-018-1896-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-018-1896-7