Abstract

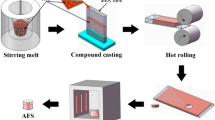

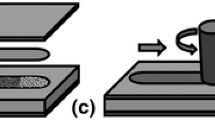

Aluminum foam sandwich was prepared by rolling-bonding/powder metallurgical foaming technology, and the effects of rolling on bond strength of face sheet/powders and powder density were studied. Moreover, the foaming agent, TiH2, was heat treated and a certain amount of Mg was added into powder in an attempt to understand how the stability and uniformity of foam was improved. The experimental results show that the foaming precursors with ideal quality were obtained by rolling-bonding process. When rolling reduction is 67%, the consistency of powders reach to 99.87%. Throughout consideration of the bonding of face sheet/core layer powders and deformation characteristic of powders, the optimum rolling reduction is 60%–70%. Cracks and drainage during foaming were inhibited by heat treatment of foaming agent TiH2 and the addition of a certain amount of Mg. The optimum heat treatment way of TiH2 is that heat preserving 1 hour at 450 °C; the amount of adding Mg is 1wt%.

Similar content being viewed by others

References

Reyes V G, Cantwell W J. Low Belocity Impact Tesponse of Novel Fiber-reinforced Aluminum Foam Sandwich Structures[J].J. Mater. Sci. Lett., 2003,22(6):417–422

Seeliger H W. Aluminium Foam Sandwich (AFS) Ready for Market Introduction[J]. Adv. Eng. Mater., 2004,6(6):448–451

Harte A M, Fleck N A, Ashby M F. Sandwich Panel Design Using Aluminum Alloy Foam[J]. Adv. Eng. Mater., 2000,2(4):219–222

Maurer M, Zhao L, Lugscheider E. Surface Refinement of Metal Foams[J]. Adv. Eng. Mater., 2002,4(10):791–797

Körner C, Singer R F. Processing of Metal Foams Challenges and Opportunities[J]. Adv. Eng. Mater., 2000,2(4):159–165

Höpler T, Schörghober M, Simancik F. Metal Foams and Porous Metal Structures[M]. Bremen: MIT-Verlag, 1999:79

Matijasevic L B, Banhart J, Fiechter S, et al. Modification of Titanium Hydride for Improved Aluminium Foam Manufacture[J]. Acta Mater., 2006,54(7):1 887–1 900

Banhart J, Bellmann D, Clemens H. Investigation of Metal Foam Formation by Microscopy and Ultra Small-angle Neutron Scattering[J]. Acta Mater., 2001,49(17):3 409–3 420

Zeppelin F, Hirscher M, Stanzick H, et al. Desorption of Hydrogen From Blowing Agents Used for Foaming Metals[J]. Comp. Sci. Tech., 2003,63(16):2 293–2 300

Duarte I, Banhart J. A Study of Aluminium Foam Formation-Kinetics and Microstructure[J]. Acta Mater., 2000, 48(9): 2 349–2 362

Stobener K, Lehmhus D, Avalle M, et al. Aluminum Goampolymer Hybrid Structures (APM aluminum foam) in Compression Testing[J]. Int. J. Solids Struct., 2008,45(21): 5 627–5 641

Zhang M, Zu GY, Yao GC. The Effect of Mg Addition on the Stability of Foams in Preparation of Foam Aluminum Sandwich [J]. Funct. Mater., 2007,38(4):576–579

Author information

Authors and Affiliations

Corresponding author

Additional information

Fundeded by the National Natural Science Foundation of China(No.50704012) and the Science and Technology Foundation of Shenyang (No. F10-205-1-59)

Rights and permissions

About this article

Cite this article

Zu, G., Song, B., Guan, Z. et al. Preparation of aluminum foam sandwich by rolling-bonding/powder metallurgy foaming technology. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 26, 671–674 (2011). https://doi.org/10.1007/s11595-011-0289-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-011-0289-y