Abstract

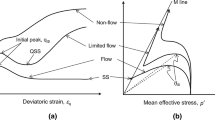

The stress–strain response of sand was observed to depend on its material state, i.e., pressure and density. Successful modelling of such state-dependent response of sand relied on the correct representation of its state-dependent stress–dilatancy behaviour. In this study, an improved fractional-order \(\left( \alpha \right)\) plasticity model for sands with a wide range of initial void ratios and pressures is proposed, based on a state-dependent fractional-order plastic flow rule and a modified yielding surface. Potential positive performances and negative limitations of the proposed approach in terms of the critical state of sand are discussed, based on the simulations of a series of drained and undrained triaxial tests of different sands. It can be found that unlike previous fractional models, the developed model can reasonably simulate the key features, e.g., strain softening/hardening, volumetric dilation/contraction, liquefaction, quasi-steady-state flow as well as steady-state flow, of sand for a wide range of initial states. However, due to typical forms of the critical-state lines being used, negative performances of the fractional approach could occur when simulating the undrained behaviour of very loose sand and the drained behaviour of very dense sand.

Similar content being viewed by others

References

Agrawal OP (2007) Fractional variational calculus in terms of Riesz fractional derivatives. J Phys A Math Theor 40(24):6287–6303

Alipour MJ, Lashkari A (2018) Sand instability under constant shear drained stress path. Int J Solids Struct 150:66–82. https://doi.org/10.1016/j.ijsolstr.2018.06.003

Azizi A (2009) Experimental study and modeling behavior of granular materials in constant deviatoric stress loading. Amirkabir University of Technology, Iran

Bandini V, Coop MR (2011) The influence of particle breakage on the location of the critical state line of sands. Soils Found 51(4):591–600

Bardet JP (1986) Bounding surface plasticity model for sands. J Eng Mech 112(11):1198–1217. https://doi.org/10.1061/(ASCE)0733-9399(1986)112:11(1198)

Been K, Jefferies MG (1985) A state parameter for sands. Géotechnique 35(2):99–112. https://doi.org/10.1016/0148-9062(85)90263-3

Been K, Jefferies MG (2004) Stress dilatancy in very loose sand. Can Geotech J 41(5):972–989. https://doi.org/10.1139/t04-038

Caputo M (1967) Linear models of dissipation whose Q is almost frequency independent—II. Geophys J Int 13(5):529–539. https://doi.org/10.1111/j.1365-246X.1967.tb02303.x

Caputo M, Fabrizio M (2015) Damage and fatigue described by a fractional derivative model. J Comput Phys 293:400–408. https://doi.org/10.1016/j.jcp.2014.11.012

Cen WJ, Luo JR, Bauer E, Zhang WD (2018) Generalized plasticity model for sand with enhanced state parameters. J Eng Mech 144(12):04018108. https://doi.org/10.1061/(ASCE)EM.1943-7889.0001534

Choo J (2018) Mohr–Coulomb plasticity for sands incorporating density effects without parameter calibration. Int J Numer Anal Methods Geomech. https://doi.org/10.1002/nag.2851

Ciantia MO, Arroyo M, O’Sullivan C, Gens A, Liu T (2018) Grading evolution and critical state in a discrete numerical model of Fontainebleau sand. Géotechnique. https://doi.org/10.1680/jgeot.17.p.023

Dafalias YF, Manzari MT (2004) Simple plasticity sand model accounting for fabric change effects. J Eng Mech 130(6):622–634. https://doi.org/10.1061/(ASCE)0733-9399(2004)130:6(622)

Eslami MM, Pradel D, Brandenberg SJ (2018) Experimental mapping of elastoplastic surfaces for sand using undrained perturbations. Soils Found 58(1):160–171. https://doi.org/10.1016/j.sandf.2017.12.004

Feia S, Sulem J, Canou J, Ghabezloo S, Clain X (2014) Changes in permeability of sand during triaxial loading: effect of fine particles production. Acta Geotech 1:19. https://doi.org/10.1007/s11440-014-0351-y

Gajo A, Muir Wood D (1999) A kinematic hardening constitutive model for sands: the multiaxial formulation. Int J Numer Anal Methods Geomech 23(9):925–965. https://doi.org/10.1002/(SICI)1096-9853(19990810)23:9%3c925:AID-NAG19%3e3.0.CO;2-M

Gajo A, Muir Wood D (1999) SevernTrent sand: a kinematic-hardening constitutive model: the q − p formulation. Géotechnique 49(5):595–614

Golchin A, Lashkari A (2014) A critical state sand model with elastic–plastic coupling. Int J Solids Struct 51(15):2807–2825. https://doi.org/10.1016/j.ijsolstr.2014.03.032

Heidarzadeh H, Oliaei M (2018) Development of a generalized model using a new plastic modulus based on bounding surface plasticity. Acta Geotech 13(4):925–941. https://doi.org/10.1007/s11440-017-0599-0

Ishihara K, Tatsuoka F, Yasuda S (1975) Undrained deformation and liquefaction of sand under cyclic stresses. Soils Found 15(1):29–44. https://doi.org/10.3208/sandf1972.15.29

Jin Y, Wu Z, Yin Z, Shen JS (2017) Estimation of critical state-related formula in advanced constitutive modeling of granular material. Acta Geotech 12(6):1329–1351. https://doi.org/10.1007/s11440-017-0586-5

Jocković S, Vukićević M (2017) Bounding surface model for overconsolidated clays with new state parameter formulation of hardening rule. Comput Geotech 83:16–29. https://doi.org/10.1016/j.compgeo.2016.10.013

Kan M, Taiebat H, Khalili N (2014) Simplified mapping rule for bounding surface simulation of complex loading paths in granular materials. Int J Geomech 14(2):239–253. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000307

Kang X, Xia Z, Chen R, Ge L, Liu X (2019) The critical state and steady state of sand: a literature review. Mar Georesour Geotechnol 37:1–14

Khalili N, Habte MA, Valliappan S (2005) A bounding surface plasticity model for cyclic loading of granular soils. Int J Numer Methods Eng 63(14):1939–1960. https://doi.org/10.1002/nme.1351

Lade PV, Nelson RB, Ito YM (1987) Nonassociated flow and stability of granular materials. J Eng Mech 113(9):1302–1318. https://doi.org/10.1061/(ASCE)0733-9399(1987)113:9(1302)

Lee KL, Seed HB (1967) Drained strength characteristics of sands. J Soil Mech Found Div 93(6):117–141

Li X (2002) A sand model with state-dependent dilatancy. Géotechnique 52(3):173–186

Li X, Dafalias Y (2000) Dilatancy for cohesionless soils. Géotechnique 50(4):449–460. https://doi.org/10.1680/geot.2000.50.4.449

Li X, Wang Y (1998) Linear representation of steady-state line for sand. J Geotech Geoenviron Eng 124(12):1215–1217. https://doi.org/10.1061/(ASCE)1090-0241(1998)124:12(1215)

Liu M, Gao Y (2016) Constitutive modeling of coarse-grained materials incorporating the effect of particle breakage on critical state behavior in a framework of generalized plasticity. Int J Geomech 17(5):04016113. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000759

Liu HB, Zou DG (2013) Associated generalized plasticity framework for modeling gravelly soils considering particle breakage. J Eng Mech 139(5):606–615. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000513

Liu HB, Zou DG, Liu JM (2014) Constitutive modeling of dense gravelly soils subjected to cyclic loading. Int J Numer Anal Methods Geomech 38(14):1503–1518. https://doi.org/10.1002/nag.2269

Liu M, Zhang Y, Zhu H (2017) 3D elastoplastic model for crushable soils with explicit formulation of particle crushing. J Eng Mech 143(12):04017140. https://doi.org/10.1061/(ASCE)EM.1943-7889.0001361

Lu D, Liang J, Du X, Ma C, Gao Z (2019) Fractional elastoplastic constitutive model for soils based on a novel 3D fractional plastic flow rule. Comput Geotech 105:277–290. https://doi.org/10.1016/j.compgeo.2018.10.004

Lü X, Huang M, Andrade JE (2018) Modeling the static liquefaction of unsaturated sand containing gas bubbles. Soils Found 58(1):122–133. https://doi.org/10.1016/j.sandf.2017.11.008

McDowell G (2002) A simple non-associated flow model for sand. Granul Matter 4(2):65–69

McDowell G, de Bono JP (2013) On the micro mechanics of one-dimensional normal compression. Géotechnique 63(11):895–908

McDowell GR, Yue P, de Bono JP (2015) Micro mechanics of critical states for isotropically overconsolidated sand. Powder Technol 283:440–446. https://doi.org/10.1016/j.powtec.2015.05.043

Meghachou M (1992) Stabilitédes sables laches: essais et modélisations. Université d’Oran

Pastor M, Zienkiewicz OC, Chan AHC (1990) Generalized plasticity and the modelling of soil behaviour. Int J Numer Anal Methods Geomech 14(3):151–190. https://doi.org/10.1002/nag.1610140302

Pedroso DM, Sheng DC, Zhao JD (2009) The concept of reference curves for constitutive modeling in soil mechanics. Comput Geotech 36(1):149–165

Pestana JM, Whittle AJ (1995) Compression model for cohesionless soils. Géotechnique 45(4):611–631

Podlubny I (1998) Fractional differential equations: an introduction to fractional derivatives, fractional differential equations, to methods of their solution and some of their applications, vol 198. Mathematics in science and engineering. Academic Press, San Diego

Russell A, Khalili N (2002) Drained cavity expansion in sands exhibiting particle crushing. Int J Numer Anal Methods Geomech 26(4):323–340

Russell AR, Khalili N (2004) A bounding surface plasticity model for sands exhibiting particle crushing. Can Geotech J 41(6):1179–1192

Russell A, Khalili N (2006) A unified bounding surface plasticity model for unsaturated soils. Int J Numer Anal Methods Geomech 30(3):181–212

Schofield A, Wroth P (1968) Critical state soil mechanics. McGraw-Hill, New York

Shi XS, Herle I (2017) Numerical simulation of lumpy soils using a hypoplastic model. Acta Geotech 12(2):349–363. https://doi.org/10.1007/s11440-016-0447-7

Shi XS, Herle I, Muir Wood D (2017) A consolidation model for lumpy composite soils in open-pit mining. Géotechnique 68(3):189–204. https://doi.org/10.1680/jgeot.16.P.054

Shi XS, Herle I, Yin J (2018) Laboratory study of the shear strength and state boundary surface of a natural lumpy soil. J Geotech Geoenviron Eng 144(12):04018093. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001987

Sumelka W (2014) Fractional viscoplasticity. Mech Res Commun 56:31–36. https://doi.org/10.1016/j.mechrescom.2013.11.005

Sumelka W, Nowak M (2016) Non-normality and induced plastic anisotropy under fractional plastic flow rule: a numerical study. Int J Numer Anal Methods Geomech 40(5):651–675. https://doi.org/10.1002/nag.2421

Sumelka W, Nowak M (2018) On a general numerical scheme for the fractional plastic flow rule. Mech Mater 116:120–129. https://doi.org/10.1016/j.mechmat.2017.02.005

Sun Y, Sumelka W (2019) State-dependent fractional plasticity model for the true triaxial behaviour of granular soil. Arch Mech 71(1):23–47. https://doi.org/10.24423/aom.3084

Sun Y, Sumelka W (2019) Fractional viscoplastic model for soils under compression. Acta Mech. https://doi.org/10.1007/s00707-019-02466-z

Sun Y, Xiao Y (2017) Fractional order plasticity model for granular soils subjected to monotonic triaxial compression. Int J Solids Struct 118–119:224–234. https://doi.org/10.1016/j.ijsolstr.2017.03.005

Sun Y, Indraratna B, Carter JP, Marchant T, Nimbalkar S (2017) Application of fractional calculus in modelling ballast deformation under cyclic loading. Comput Geotech 82:16–30. https://doi.org/10.1016/j.compgeo.2016.09.010

Sun Y, Gao Y, Zhu Q (2018) Fractional order plasticity modelling of state-dependent behaviour of granular soils without using plastic potential. Int J Plasticity 102:53–69. https://doi.org/10.1016/j.ijplas.2017.12.001

Sun Y, Chen C, Song S (2018) Generalized fractional flow rule and its modelling of the monotonic and cyclic behavior of granular soils. In: Zhou A, Tao J, Gu X, Hu L (eds) Proceedings of GeoShanghai 2018 international conference: fundamentals of soil behaviours, Singapore, 2018//2018. Springer, Singapore, pp 299–307

Sun Y, Gao Y, Shen Y (2019) Mathematical aspect of the state-dependent stress-dilatancy of granular soil under triaxial loading. Géotechnique 69(2):158–165. https://doi.org/10.1680/jgeot.17.t.029

Sun Y, Gao Y, Song S, Chen C (2019) Three-dimensional state-dependent fractional plasticity model for soils. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001353

Taiebat M, Jeremić B, Dafalias YF, Kaynia AM, Cheng Z (2010) Propagation of seismic waves through liquefied soils. Soil Dyn Earthq Eng 30(4):236–257. https://doi.org/10.1016/j.soildyn.2009.11.003

Verdugo R, Ishihara K (1996) The steady state of sandy soils. Soils Found 36(2):81–91. https://doi.org/10.3208/sandf.36.2_81

Wan R, Guo P (1998) A simple constitutive model for granular soils: modified stress-dilatancy approach. Comput Geotech 22(2):109–133. https://doi.org/10.1016/s0266-352x(98)00004-4

Wan R, Nicot F, Darve F (2009) Micromechanical formulation of stress dilatancy as a flow rule in plasticity of granular materials. J Eng Mech 136(5):589–598. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000105

Wang Z, Dafalias Y, Li X, Makdisi F (2002) State pressure index for modeling sand behavior. J Geotech Geoenviron Eng 128(6):511–519. https://doi.org/10.1061/(ASCE)1090-0241(2002)128:6(511)

Xiao Y, Liu H (2016) Elastoplastic constitutive model for rockfill materials considering particle breakage. Int J Geomech 17(1):04016041. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000681

Xiao Y, Liu H, Chen Y, Jiang J (2014) Bounding surface plasticity model incorporating the state pressure index for rockfill materials. J Eng Mech 140(11):04014087. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000802

Xiao Y, Liu H, Chen Y, Jiang J (2014) Bounding surface model for rockfill materials dependent on density and pressure under triaxial stress conditions. J Eng Mech 140(4):04014002. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000702

Xiao Y, Sun Y, Yin F, Liu H, Xiang J (2017) Constitutive modeling for transparent granular soils. Int J Geomech 17(7):04016150. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000857

Xiao Y, Sun Z, Stuedlein AW, Wang C, Wu Z, Zhang Z (2019) Bounding surface plasticity model for stress–strain and grain-crushing behaviors of rockfill materials. Geosci Front. https://doi.org/10.1016/j.gsf.2018.1010.1010

Yao Y, Wang N (2014) Transformed stress method for generalizing soil constitutive models. J Eng Mech 140(3):614–629. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000685

Yao YP, Sun DA, Luo T (2004) A critical state model for sands dependent on stress and density. Int J Numer Anal Methods Geomech 28(4):323–337. https://doi.org/10.1002/nag.340

Yao YP, Hou W, Zhou AN (2009) UH model: three-dimensional unified hardening model for overconsolidated clays. Géotechnique 59(5):451–469. https://doi.org/10.1680/geot.2007.00029

Yao YP, Kong L, Zhou A, Yin J (2014) Time-dependent unified hardening model: three-dimensional elastoviscoplastic constitutive model for clays. J Eng Mech 141(6):04014162. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000885

Yao YP, Liu L, Luo T, Tian Y, Zhang JM (2019) Unified hardening (UH) model for clays and sands. Comput Geotech 110:326–343. https://doi.org/10.1016/j.compgeo.2019.02.024

Yin Z, Wu Z, Hicher P (2018) Modeling monotonic and cyclic behavior of granular materials by exponential constitutive function. J Eng Mech 144(4):04018014. https://doi.org/10.1061/(ASCE)EM.1943-7889.0001437

Yu F (2017) Particle breakage and the critical state of sands. Géotechnique 67(8):713–719. https://doi.org/10.1680/jgeot.15.P.250

Acknowledgements

The first author would like to appreciate Prof. Wen Chen for his lifelong inspiration. The financial support provided by the National Key R&D Program of China (2016YFC0800205) National Natural Science Foundation of China (Grant Nos. 41630638, 51890912, 51808191), the National Key Basic Research Program of China (“973” Program) (Grant No. 2015CB057901) and the Humboldt Research Foundation, Germany, is appreciated. The second author also acknowledges the support of the National Science Centre, Poland, under Grant No. 2017/27/B/ST8/00351.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

In order to derive Eq. (17), the following analytical solutions of the power-law functions, \((\sigma^{\prime} - \sigma^{\prime}_{{\mathrm{c}}} )^{\mu }\) and \((\sigma^{\prime}_{{\mathrm{c}}} - \sigma^{\prime})^{\mu }\), are needed:

where \(\mu\) is the power index. Details for deriving Eqs. (25) and (26) can be found in [44] and thus not repeated here for simplicity. Accordingly, Eq. (14) with \(\beta = 0\) should be rearranged as:

and

Then, substituting Eqs. (27) and (28) into Eqs. (25) and (26), respectively, one has:

Further substituting Eq. (2) into Eqs. (29) and (30), a unique stress–dilatancy equation is obtained:

Rights and permissions

About this article

Cite this article

Sun, Y., Sumelka, W. & Gao, Y. Advantages and limitations of an α-plasticity model for sand. Acta Geotech. 15, 1423–1437 (2020). https://doi.org/10.1007/s11440-019-00877-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-019-00877-9