Abstract

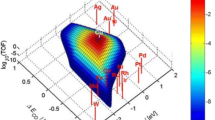

Hexamethylenediamine (HMDA) is an important reagent for the synthesis of Nylon-6,6, and it is usually produced by the hydrogenation of adiponitrile using a toxic reagent of hydrocyanic acid. Herein, we developed an environmental friendly route to produce HMDA via catalytic reductive amination of 1,6-hexanediol (HDO) in the presence of hydrogen. The activities of several heterogeneous metal catalysts such as supported Ni, Co, Ru, Pt, Pd catalysts were screened for the present reaction in supercritical ammonia without any additives. Among the catalysts examined, Ru/Al2O3 presented a high catalytic activity and highest selectivity for the desired product of HMDA. The high performance of Ru/Al2O3 was discussed based on the Ru dispersion and the surface properties like the acid-basicity. In addition, the reaction parameters such as reaction temperature, time, H2 and NH3 pressure were examined, and the reaction processes were discussed in detail.

Similar content being viewed by others

References

Dros AB, Larue O, Reimond A, De Campo F, Pera-Titus M. Green Chem, 2015, 17: 4760–4772

Roundhill DM. Chem Rev, 1992, 92: 1–27

Fischer A, Mallat T, Baiker A. Catal Today, 1997, 37: 167–189

Bähn S, Imm S, Neubert L, Zhang M, Neumann H, Beller M. ChemCatChem, 2011, 3: 1853–1864

Shimizu K. Catal Sci Technol, 2015, 5: 1412–1427

Zhang Y, Qi X, Cui X, Shi F, Deng Y. Tetrahedron Lett, 2011, 52: 1334–1338

Tuteja J, Choudhary H, Nishimura S, Ebitani K. ChemSusChem, 2014, 7: 96–100

Xiao B, Zheng M, Li X, Pang J, Sun R, Wang H, Pang X, Wang A, Wang X, Zhang T. Green Chem, 2016, 18: 2175–2184

Gunanathan C, Milstein D. Angew Chem Int Ed, 2008, 47: 8661–8664

Molnár Á, Sirokmán G, Bartók M. J Mol Catal, 1983, 19: 25–33

Sirokmán G, Molnár Á, Bartók M. J Mol Catal, 1983, 19: 35–40

Fischer A, Maciejewski M, Bürgi T, Mallat T, Baiker A. J Catal, 1999, 183: 373–383

Fischer A, Mallat T, Baiker A. Angew Chem Int Ed, 1999, 38: 351–354

Fischer A, Mallat T, Baiker A. J Mol Catal A-Chem, 1999, 149: 197–204

Jenzer G, Mallat T, Baiker A. Catal Lett, 1999, 61: 111–114

Fischer A, Mallat T, Baiker A. J Catal, 1999, 182: 289–291

Imm S, Bähn S, Zhang M, Neubert L, Neumann H, Klasovsky F, Pfeffer J, Haas T, Beller M. Angew Chem Int Ed, 2011, 50: 7599–7603

Baumann W, Spannenberg A, Pfeffer J, Haas T, Köckritz A, Martin A, Deutsch J. Chem Eur J, 2013, 19: 17702–17706

Pingen D, Diebolt O, Vogt D. ChemCatChem, 2013, 5: 2905–2912

Pfützenreuter R, Rose M. ChemCatChem, 2016, 8: 251–255

Mormul J, Breitenfeld J, Trapp O, Paciello R, Schaub T, Hofmann P. ACS Catal, 2016, 6: 2802–2810

Horlenko T, Tatum HW. Process for producing hexamethylenediamine from 1-6-hexanediol. US Patent, 3268588, 1966-08-23

Winderl S, Haarer E, Corr H, Hornberger P. Production of diaminoalkanes. US Patent, 3270059, 1966-08-30

Romanelli GP, Autino JC, Blanco MN, Pizzio LR. Appl Catal A-Gen, 2005, 295: 209–215

Altass HM, Khder AERS. J Mol Catal A-Chem, 2016, 411: 138–145

Srinivas N, Venu Gopal D, Srinivas B, Kulkarni SJ, Subrahmanyam M. Microporous Mesoporous Mater, 2002, 51: 43–50

Zhao F, Ikushima Y, Arai M. J Catal, 2004, 224: 479–483

Acknowledgments

This work was supported by the National Basic Research Program of China (2016YFA0602900), Youth Innovation Promotion Association CAS (2016206), and Jilin Provincial Science and Technology Program of China (20150301012GX).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Li, Y., Cheng, H., Zhang, C. et al. Reductive amination of 1,6-hexanediol with Ru/Al2O3 catalyst in supercritical ammonia. Sci. China Chem. 60, 920–926 (2017). https://doi.org/10.1007/s11426-017-9049-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-017-9049-5