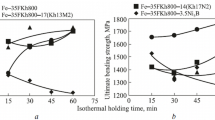

The production conditions and mechanical and tribotechnical properties of iron–high-carbon ferrochrome FKh800 materials doped with nickel boride have been studied. It is shown that Ni3B additions promote the formation of a multiphase microheterogeneous matrix-reinforced structure consisting of chromium steel and solid inclusions of complex chromium–iron carbides such as Me7C3 and Me23C6. When the doping content increases from 3.5 to 7.0 wt.%, complex Fe–Cr carbides and carboborides form, decreasing the hardness and bending strength and increasing the abrasive wear resistance of the base material from 5.0 to 12.2 km/mm. The Fe–35% FKh800 materials containing 5–7 wt.% Ni3B are found to be promising as they combine acceptable mechanical properties and improved abrasive wear resistance.

Similar content being viewed by others

References

I. D. Radomyselsky, G. G. Serdyuk, and N. I. Shcherban, Structural Powder Materials [in Russian], Tekhnika, Kyiv (1985), p. 152.

I. M. Fedorchenko, I. N. Frantsevich, I. D. Radomyselsky, et al., Powder Metallurgy. Materials, Technology, Properties, and Applications: Handbook [in Russian], Naukova Dumka, Kyiv (1985), p. 624.

V. A. Maslyuk, A. A. Bondar, V. B. Kuras’, et al., “Structure and properties of iron–high-carbon ferrochrome powder composites,” Powder Metall. Met. Ceram., 52, No. 5–6, 291–297 (2013).

S. M. Vinarov (ed.), V. A. Mchedlishvili, and V. V. Khovrin, Boron, Calcium, Niobium, and Zirconium in Cast Iron and Steel [Russian translation], Metallurgizdat, Moscow (1971), p. 459.

S. S. Ermakov and N. F. Vyaznikov, Powder Steels and Parts [in Russian], 4th ed., Mashinostroenie, Leningrad (1990), p. 319.

V. A. Maslyuk, Y. A. Sytnik, M. I. Podoprygora, and R. V. Yakovenko, “The effect of chromium steels and nickel boride additives on the structure and properties of iron–high-carbon ferrochrome FKh800 powder composites,” Powder Metall. Met. Ceram., 54, No. 5–6, 292–297 (2015).

ISO 4498-1:1990. Sintered Metal Materials, Excluding Hardmetals—Determination of Apparent Hardness. Part 1. Materials of Essentially Uniform Section Hardness, ed. 1990-08-2.

ISO 3327:2009. Hardmetals—Determination of Transverse Rupture Strength, ed. 2009-05-15.

G. A. Baglyuk, S. G. Napara-Volgina, L. N. Orlova, et al., “Production of boron-containing powder steels using master alloys and boron carbide,” Powder Metall. Met. Ceram., 49, No. 11–12, 618–654 (2011).

Yu. S. Borisov, V. E. Oliker, E. A. Astakhov, et al., “Structure and properties of gas-thermal coatings of Fe–B–C and Fe–Ti–B–C alloys,” Powder Metall. Met. Ceram., 26, No. 4, 313–318 (1987).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 57, Nos. 3–4 (520), pp. 62–70, 2018.

Rights and permissions

About this article

Cite this article

Maslyuk, V.A., Karaimchuk, E.S., Podoprygora, M.I. et al. Structure and Mechanical and Tribotechnical Properties of Iron–High-Carbon Ferrochrome Doped with Ni3B Additions. Powder Metall Met Ceram 57, 175–181 (2018). https://doi.org/10.1007/s11106-018-9965-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-018-9965-1