Abstract

The transition behavior of an Al-rich amorphous oxide layer to an external Al2O3 layer on Fe–(4, 24)Cr–(6, 10)Al (at.%) alloys was investigated during heating to 1000 °C at a heating rate of 50 °C/min, by means of in situ high-temperature X-ray diffraction measurement and TEM observation. In the alloy containing 6Al, internal amorphous Al2O3 was initially developed below the Al-rich amorphous surface layer. The amorphous internal precipitates transformed to be crystalline and grew laterally with time. The internal precipitates subsequently connected with each other to form a continuous α-Al2O3 scale. In the case of 10Al alloy, an Al-rich amorphous layer transitioned to a crystalline α-Al2O3 layer from the interface between transient/amorphous layers during heating. The Al2O3 scale developed on high Al alloys contained Fe and Cr with relatively higher contents, but that formed on low Al alloy contained low Fe and Cr. The effect of Cr on promoting an external Al2O3 scale formation was found to be weaker for alloys with higher Al content compared to the alloys with lower Al content, if Al2O3 scale was directly transitioned from the amorphous layer.

Similar content being viewed by others

References

F. A. Golightly, G. C. Wood and F. H. Stott, Oxidation of Metals 14, 217 (1980).

B. H. Kear, L. P. Lemaire, D. E. Fornwalt and F. S. Pettit, Oxidation of Metals 3, 557 (1971).

M. W. Brumm and H. J. Grabke, Corrosion Science 33, 1677 (1992).

Y. Kitajima, S. Hayashi, T. Nishimoto, T. Narita and S. Ukai, Oxidation of Metals 73, 375 (2010).

S. Yoneda, S. Hayashi, I. Saeki and S. Ukai, Oxidation of Metals 86, 357 (2016).

S. Yoneda, S. Hayashi and S. Ukai, Oxidation of Metals (2017). doi:10.1007/s11085-017-9761-1.

T. Fujimura and S.-I. Tanaka, Journal of Materials Science 34, 425 (1999).

I. E. Reimanis, K. P. Trumble, K. A. Rogers and B. J. Dalgleish, Journal of the American Ceramic Society 80, 424 (1997).

D. Renusch, M. Grimsditch, I. Koshelev, B. W. Veal and P. Y. Hou, Oxidation of Metals 48, 471 (1997).

S. Hayashi, I. Saeki, Y. Nishiyama, T. Doi, S. Kyo and M. Segawa, Materials Science Forum 696, 63 (2011).

S. Hayashi, Y. Takada, I. Saeki, A. Yamauchi, Y. Nishiyama, T. Doi, S. Kyo and M. Sato, Materials and Corrosion 63, 862 (2012).

M. Fujita, K. Inukai, S. Sakida, T. Nanba, J. Ommyoji, A. Yamaguchi and Y. Miura, Journal of the Society of Materials Science 56, 526 (2007).

F. A. Elrefaie and W. W. Smeltzer, Metallurgical Transactions B 14B, 85 (1983).

Acknowledgements

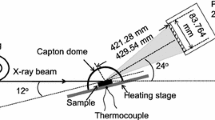

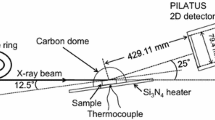

Part of this work was supported by “Research and development of oxide dispersion strengthened (ODS) ferritic steel fuel cladding for maintaining fuel integrity at high-temperature accident conditions” entrusted to Hokkaido University by the Ministry of Education, Culture, Sports, Science and Technology, MEXT, Japan and JSPS KAKENHI Grant Number JP16K14436. The synchrotron radiation experiments were performed at the BL19B2 of SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (Proposal No. 2015A1727). The authors greatly appreciate Dr. M. Sato for his support for X-ray diffraction measurement at SPring-8. TEM characterization was conducted under the program of NIMS microstructural characterization platform as a program of “Nanotechnology Platform” of the MEXT.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoneda, S., Hayashi, S. & Ukai, S. The Transition from Transient Oxide to Protective Al2O3 Scale on Fe–Cr–Al Alloys During Heating to 1000 °C. Oxid Met 89, 81–97 (2018). https://doi.org/10.1007/s11085-017-9778-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-017-9778-5