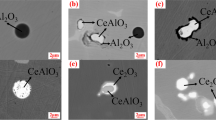

A comparative study is provided for the effect of Si and Fe impurities in relation to their concentration in the structure, phase composition, and mechanical properties of alloy Al–0.2Y–0.3Er–0.2Zr–0.05Sc. With a content of Fe and Si (in the amount of 0.15%), presence is noted of phases formed by iron and silicon impurities with an increased concentration of Zr, Er, and Y. These phases are not found in the structure of alloy with a lower concentration of Fe and Si (0.01%). Due to dilution of aluminum solid solution with Zr, Er and Y, alloy with an increased Fe and Si (0.15%) content shows a weaker hardening effect during annealing compared to alloy having a more supersaturated solid solution. Sc in both alloys is evenly distributed within the matrix of aluminum solid solution and does not form phases during crystallization. It is shown that the temperature for the start of recrystallization for these alloys is in the range 500–550 °C. The set of standard mechanical properties for sheet produced from these alloys is almost at the same level: yield strength of 155 MPa, ultimate strength of 166 MPa, elongation at 11.2% for alloy with 0.15% (Fe and Si) and 8.7% for alloy with 0.01% (Fe and Si). It is noted that after annealing (200 °C, 1 h) sheets hardness increases by 5 HV, which may point to aluminum solid solution decomposition.

Similar content being viewed by others

References

C. Booth-Morrison, D. C., Dunand, and D. N. Seidman, “Coarsening resistance at 400 °C of precipitation-strengthened Al–Zr–Sc–Er alloys,” Acta Mater., 59, 7029–7042 (2011).

S. P. Wen, K. Y. Gao, Y. Li Y, et al., “Synergetic effect of Er and Zr on the precipitation hardening of Al–Er–Zr alloy,” Scr. Mater., 65, 592–595 (2011).

C. Booth-Morrison, D. N. Seidman, and D. C. Dunand, “Effect of Er additions on ambient and high-temperature strength of precipitation-strengthened Al–Zr–Sc–Si alloys,” Acta Mater., 60, 3643–3654 (2012).

S. P. Wen, K. Y. Gao, H. Huang, et al., “Precipitation evolution in Al–Er–Zr alloys during aging at elevated temperature,” J. All. Comp., 574, 92–97 (2013).

Y. Zhang, H. Gao, Y. Kuai, et al., “Effects of Y additions on the precipitation and recrystallization of Al–Zr alloys,” Mater. Charact., 86, 1–8 (2013).

Y. Zhang, K. Gao, S. Wen, et al., “The study on the coarsening process and precipitation strengthening of Al3Er precipitate in Al–Er binary alloy,” J. Alloys Compd., 610, 27–34 (2014).

Y. Zhang, J. Gu, Y. Tian, et al., “Microstructural evolution and mechanical property of Al–Zr and Al–Zr–Y alloys,” Mater. Sci. Eng., A616, 132–140 (2014).

N. Q. Vo, D. C. Dunand, and D. N. Seidman, “Improving aging and creep resistance in a dilute Al–Sc alloy by microalloying with Si, Zr and Er,” Acta Mater., 63, 73–85 (2014).

A. De Luca, D. C. Dunand, and D. N. Seidman, “Mechanical properties and optimization of the aging of a dilute Al–Sc–Er–Zr–Si alloy with a high Zr/Sc ratio,” Acta Mater., 119, 35–42 (2016).

H. Gao, W. Feng, and Y. Wang, “Structural and compositional evolution of Al3(Zr,Y) precipitates in Al–Zr–Y alloy,” Mater. Charact., 121, 195–198 (2016).

H. Gao, W. Feng, J. Gu, et al., “Aging and recrystallization behavior of precipitation strengthened Al–0.25Zr–0.03Y alloy,” J. All. Comp., 696, 1039–1045 (2017).

A. V. Pozdniakov, A. A. Aytmagambetov, S. V. Makhov, and V. I. Napalkov, “Effect of impurities of Fe and Si on the structure and strengthening upon annealing of the Al–0.2% Zr–0.1% Sc alloys with and without Y additive,” The Phys. Met. Metall., 118, No. 5, 470–484 (2017).

A. V. Pozdnyakov, A. A. Osipenkova, D. A. Popov, et al., “Effect of low additions of Y, Sm, Gd, Hf and Er on the structure and hardness of alloy Al–0.2% Zr–0.1% Sc,” Met. Sci. Heat Treat., 58, No. 9–10, 537–542 (2017).

A. V. Pozdniakov, R. Y. Barkov, A. S. Prosviryakov, et al., “Effect of Zr on the microstructure, recrystallization behavior, mechanical properties and electrical conductivity of the novel Al–Er–Y alloy,” J. Alloys Compounds, 765, 15 October, 1–6 (2018).

L. Z. He, X. H. Li, X. T. Liu, et al., “Effects of homogenization on microstructures and properties of a new type Al–Mg–Mn–Zr–Ti–Er alloy,” Mater. Sci. Eng., A.527, 7510–7518 (2010).

H. L. Hao, D. R. Ni, Z. Zhang, et al., “Microstructure and mechanical properties of Al–Mg–Er sheets jointed by friction stir welding,” Mater. Des., 52, 706–712 (2013).

Ya. Dongxi, Li. Xiaoyan, H. Dingyong, and H. Hui, “Effect of minor Er and Zr on microstructure and mechanical properties of Al–Mg–Mn alloy (5083) welded joints,” Mater. Sci. & Eng., A. 561, 226–231 (2013).

M. Song, K. Du, Z. Y. Huang, et al., “Deformation-induced dissolution and growth of precipitates in an Al–Mg–Er alloy during high-cycle fatigue,” Acta Mater., 81, 401–4019 (2014).

S. P. Wen, W. Wang, W. H. Zhao, et al., “Precipitation hardening and recrystallization behavior of Al–Mg–Er–Zr alloys,” J. All. Comp., 687, 143–151 (2016).

A. V. Pozdniakov, V. Yarasu, R. Yu. Barkov, et al., “Microstructure and mechanical properties of novel Al–Mg–Mn–Zr–Sc–Er alloy,” Mat. Let., 202, 116–119 (2017).

H. Che, X. Jiang, N. Qiao, and X. Liu, “Effects of Er/Sr/Cu additions on the microstructure and mechanical properties of Al–Mg alloy during hot extrusion,” J. All. Comp., 708, 662–670 (2017).

F. Cao, X. Zhu, Sh. Wang, et al., “Quasi-superplasticity of a banded-grained Al–Mg–Y alloy processed by continuous casting extrusion,” Mater. Sci. Eng., A690, 433–445 (2017).

R. Yu. Barkov, A. V. Pozdniakov, E. Tkachuk, and V. S. Zolotorevskiy, “Effect of Y on microstructure and mechanical properties of Al–Mg–Mn–Zr–Sc alloy with low Sc content,” Mat. Let., 217, 135–138 (2018).

Y. I. Kosov and V. Y. Bazhin, “Synthesis of an aluminum–erbium master alloy from chloride–fluoride melts,” Russian Metallurgy (Metally), 2018, No. 2, 139–148 (2018).

V. Y. Bazhin, Y. I. Kosov, O. L. Lobacheva, and N. V. Dzhevaga, “Synthesis of aluminum-based scandium–yttrium master alloys, Russian Metallurgy (Metally), 2015, No. 7, 516–520 (2015).

Work was carried out with support of the Russian Scientific Fund (project No. 17-79-10256).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 63, No. 1, pp. 65–70, January, 2019.

Rights and permissions

About this article

Cite this article

Pozdnyakov, A.V., Barkov, R.Y. Effect of Impurities on the Phase Composition and Properties of a New Alloy of the Al–Y–Er–Zr–Sc System. Metallurgist 63, 79–86 (2019). https://doi.org/10.1007/s11015-019-00796-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-019-00796-w