Abstract

The production technology has a significant impact on physical and mechanical properties of ceramic materials. The common manufacturing processes are pressing, extrusion, or casting. Porcelain products are often formed by pressing, which increases their mechanical properties. Therefore, samples made from electroporcelain mixture for production of high-voltage insulators are studied using pressing with five different compression pressures from 70 MPa up to 110 MPa. Young’s modulus, thermal expansion, and bulk density are investigated during firing in temperature interval from 25 to 1100 °C. All measurements are carried out in the same temperature program with a heating rate of 5 °C min−1 in static air atmosphere. The influence of pressing and heating on Young’s modulus, thermal expansion, and bulk density of electroporcelain mixture is examined.

Similar content being viewed by others

References

Bergaya F, Theng BKG, Lagaly G. Handbook of clay science. Amsterdam: Elsevier; 2006.

Murray HH. Applied clay mineralogy today and tomorrow. Clay Miner. 1999;34:39–49.

Carretero MI, Dondi M, Fabbri B, Raimondo M. The influence of shaping and firing technology on ceramic properties of calcareous and non-calcareous illitic-chloritic clays. Appl Clay Sci. 2002;20:301–6.

Rice RW. Ceramic fabrication technology. Boca Raton: CRC Press; 2002.

Ferrari S, Gualtieri A. The use of illitic clays in the production of stoneware tile ceramics. Appl Clay Sci. 2006;32:73–81.

Bennour A, Mahmoudi S, Srasra E, Hatira N, Boussen S, Ouaja M, Zargouni F. Identification and traditional ceramic application of clays from the Chouamekh region in south-eastern Tunisia. Appl Clay Sci. 2015;118:212–20.

EN 60672-3 (1997) Ceramic and glass-insulating materials part 3: specifications for individual materials.

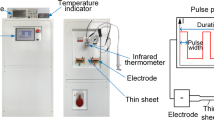

Štubňa I, Húlan T, Trník A, Vozár L. Uncertainty in the determination of Young‘s modulus of ceramics using the impulse excitation technique at elevated temperatures. Acta Acust United Acust. 2018;104:269–76.

Štubňa I, Trník A, Harcek M, Vrabec M, Matfiak J. The dependance of Young’s modulus of green electroceramic body on moisture and compression pressure. Silika. 2004;14:172–4 (in Slovak).

Štubňa I, Trník A, Harcek M, Vrabec M, Matfiak J. The dependance of mechanical strength of green electroceramic body on moisture and compression pressure. Silika. 2005;15:16–7 (in Slovak).

Húlan T, Trník A, Štubňa I, Bačík P, Kaljuvee T, Vozár L. Development of Young’s modulus of illitic clay during heating up to 1100 °C. Mater Sci Medzg. 2015;21:429–34.

Knapek M, Húlan T, Minárik P, Dobroň P, Štubňa I, Stráská J, Chmelík F. Study of microcracking in illite-based ceramics during firing. J Eur Ceram Soc. 2016;36:221–6.

Al-Shantir O, Trník A. Influence of compression pressure on Young’s modulus of ceramic samples. AIP Conf Proc. 2017;1866:040001.

Al-Shantir O, Trník A, Csáki Š. Influence of firing temperature and compacting pressure on density and Young’s modulus of electroporcelain. AIP Conf Proc. 2018;1988:020001.

Podoba R, Trník A, Podobník Ľ. Upgrading of TGA/DTA analyzer derivatograph. Építőanyag. 2012;64:28–9.

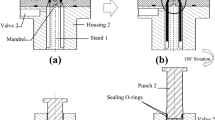

Jankula M, Šín P, Podoba R, Ondruška J. Typical problems in push-rod dilatometry analysis. Építôanyag. 2013;65:11–4.

ASTM C1259-15. Standard test method for dynamic Young’s modulus, shear modulus, and Poisson’s ratio for advanced ceramics by impulse excitation of vibration. West Conshohocken: ASTM International; 2015.

Štubňa I, Šín P, Trník A, Veinthal R. Mechanical properties of kaolin during heating. Key Eng Mater. 2013;527:14–9.

Ptáček P, Kubátová D, Havlica J, Brandštetr J, Šoukal F, Opravil T. The non-isothermal kinetic analysis of the thermal decomposition of kaolinite by thermogravimetric analysis. Powder Technol. 2010;204:222–7.

Ondro T, Húlan T, Vitázek I. Non-isothermal kinetic analysis of the dehydroxylation of kaolinite in dynamic air atmosphere. Acta Technol Agric. 2017;20:52–6.

Obada DO, Dodoo-Arhin D, Dauda M, Anafi FO, Ahmed AS, Ajayi OA. The impact of kaolin dehydroxylation on the porosity and mechanical integrity of kaolin based ceramics using different pore formers. Results Phys. 2017;7:2718–27.

Húlan T, Trník A, Medveď I. Kinetics of thermal expansion of illite-based ceramics in the dehydroxylation region during heating. J Therm Anal Calorim. 2017;127:291–8.

Ptáček P, Šoukal F, Opravil T, Nosková M, Havlica J, Brandštetr J. The kinetics of Al-Si spinel phase crystallization from calcined kaolin. J Solid State Chem. 2010;183:2565–9.

Heimann RB. Classic and advanced ceramics: from fundamentals to applications. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA; 2010.

Trník A, Moravčíková J, Keppert M, Medveď I. Isothermal thermodilatometric study of sintering in electroceramics. Sci Sinter. 2013;45:3–12.

Húlan T, Trník A, Medveď I. Kinetics of thermal expansion of illite-based ceramics in the dehydroxylation region during heating. J Therm Anal Calorim. 2017;127:1–8.

Venturelli C, Paganelli M. Sintering behaviour of clays for the production of ceramics. Process Eng. 2007;84:5–8.

Ptáček P, Křečková M, Šoukal F, Opravil T, Havlica J, Brandštetr J. The kinetics and mechanism of kaolin powder sintering I. The dilatometric CRH study of sinter-crystallization of mullite and cristobalite. Powder Technol. 2012;232:24–30.

Emmerich W-D, Hayhurst J, Kaisersberger E. High temperature dilatometer study of special ceramics and their sintering kinetics. Thermochim Acta. 1986;106:71–8.

Kováč J, Trník A, Medveď I, Vozár L. Influence of calcite in a ceramic body on its thermophysical properties. J Therm Anal Calorim. 2013;114:963–70.

Trník A, Štubňa I, Sokolář R, Medveď I. Use of fly ash in ceramic tiles: elastic properties during firing. J Ceram Soc Jpn. 2013;121:925–9.

Acknowledgements

This work was supported by the Grants UGA VII/1/2019 from Constantine the Philosopher University in Nitra and by RVO: 11000.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Shantir, O., Csáki, Š., Veverka, J. et al. The influence of compression pressure on thermal expansion, bulk density, and Young’s modulus of electroporcelain mixture up to 1100 °C. J Therm Anal Calorim 138, 2035–2042 (2019). https://doi.org/10.1007/s10973-019-08490-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08490-4