Abstract

Reactivity of nanosized objects is a hot topic in modern solid-state chemistry and materials science. The present work is focused on the interaction between multi-walled carbon nanotubes (MWCNTs) and metallic titanium during high-energy ball milling and thermal explosion, a rapid temperature rise in a mixture caused by an exothermic reaction ignited by external heating and occurring throughout the sample volume. A fundamental property of the nanocomposite mixture—the ability of its components to react in the combustion mode—is explained; an analysis of the dependence of the combustion characteristics of the nanocomposites on the milling duration of powder mixtures is provided. The phase and structural transformations of the Ti-MWCNT mixtures have been analyzed using X-ray diffraction and transmission electron microscopy. It was found that the ball-milled powders contain nanostructured titanium, nanotube fragments, amorphous carbon and nanosized carbon-deficient titanium carbide TiCx. Within the nanocomposite powder particles, TiCx nanoparticles are covered with layers of amorphous carbon. Thermal explosion was observed in Ti-4mass%MWCNT mixtures milled for 1.5–7 min. Shorter milling times were apparently not sufficient for establishing a proper interfacial contact, while longer milling times led to the extensive formation of titanium carbide TiCx, which acted as a barrier lowering the heat release by the mixture upon ignition. Both the ignition temperature of Ti-4mass%MWCNT and the maximum temperature developed during thermal explosion decrease with the milling time. A comparison of the behavior of MWCNT with that of carbon black under conditions of thermal explosion in the mixtures with titanium is also presented.

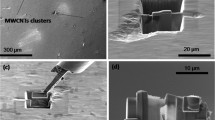

Graphical abstract

Similar content being viewed by others

References

De Volder MFL, Tawfick SH, Baughman RH, Hart AJ. Carbon nanotubes: present and future commercial applications. Science. 2013;339:535–9.

Augusto Guisard Restivo T, Durazzo M, de Regina Homem Mello-Castanho S, Cugler Moreira A, Graciano S, Bridi Telles V, Alberto Soares Tenorio J. Low-temperature densification of ceramics and cermets by the intermediary stage activated sintering method. J Therm Anal Calorim. 2018;131:249–58.

Ebrahimi H, Roghani-Mamaqani H, Salami-Kalajahi M. Preparation of carbon nanotube-containing hybrid composites from epoxy, novolac, and epoxidized novolac resins using sol–gel method. J Therm Anal Calorim. 2018;132:513–24.

Kondoh K., Threrujirapapong T., Imai H., Umeda J., Fugetsu B. CNTs/TiC reinforced titanium matrix nanocomposites via powder metallurgy and its microstructural and mechanical properties. J Nanomater. 2008: Article ID 127538.

Kondoh K, Threrujirapapong T, Imai H, Umeda J, Fugetsu B. Characteristics of powder metallurgy pure titanium matrix composite reinforced with multiwall carbon nanotubes. Compos Sci Technol. 2009;69:1077–81.

Kondoh K, Threrujirapapong T, Umeda J, Fugetsu B. High-temperature properties of extruded titanium composites fabricated from carbon nanotubes coated titanium powder by spark plasma sintering and hot extrusion. Compos Sci Technol. 2012;72:1291–7.

Feng X, Sui JH, Feng Y, Cai W. Preparation and elevated temperature compressive properties of multi-walled carbon nanotube reinforced Ti composites. Mater Sci Eng A. 2010;527:1586–9.

Guiderdoni CH, Estournes C, Peigney A, Weibel A, Turq V, Laurent CH. The preparation of double-walled carbon nanotube/Cu composites by spark plasma sintering, and their hardness and friction properties. Carbon. 2011;49:4535–43.

Tsai PC, Jeng YR. Experimental and numerical investigation into the effect of carbon nanotube buckling on the reinforcement of CNT/Cu composites. Compos Sci Technol. 2013;79:28–34.

Suarez S, Lasserre F, Mücklich F. Mechanical properties of MWCNT/Ni bulk composites: influence of the microstructural refinement on the hardness. Mater Sci Eng A. 2013;587:381–6.

Lee J, Hwang J, Lee D, Ryu HJ, Hong SH. Enhanced mechanical properties of spark plasma sintered NiTi composites reinforced with carbon nanotubes. J Alloys Compd. 2014;617:505–10.

Li CD, Wang XJ, Liu WQ, Wu K, Shi HL, Ding C, Hu XS, Zheng MY. Microstructure and strengthening mechanism of carbon nanotubes reinforced magnesium matrix composite. Mater Sci Eng A. 2014;597:264–9.

Nguyen J, Holland TB, Wen H, Fraga M, Mukherjee A, Lavernia E. Mechanical behavior of ultrafine-grained Ni–carbon nanotube composite. J Mater Sci. 2014;49:2070–7.

Wang FC, Zhang ZH, Sun YJ, Liu Y, Hu ZY, Wang H, Korznikov AV, Korznikova E, Liu ZF, Osamu S. Rapid and low temperature spark plasma sintering synthesis of novel carbon nanotube reinforced titanium matrix composites. Carbon. 2015;95:396–407.

Rogachev AS, Mukasyan AS. Combustion for material synthesis. Boca Raton: CRC Press; 2014.

Groven LJ, Puszynski JA. Effect of carbon nanotube addition on morphology of SHS synthesized materials. Int J Self-Propag High-Temp Synth. 2007;16:189–98.

Jin S, Shen P, Zhou D, Jiang Q. Self-propagating high-temperature synthesis of nano-TiCx particles with different shapes by using carbon nano-tube as C source. Nanoscale Res Lett. 2011;6:515.

Wang L, Qiu F, Ouyang L, Wang H, Zha M, Shu S, Zhao Q, Jiang Q. A novel approach of using ground CNTs as the carbon source to fabricate uniformly distributed nano-sized TiCx/2009Al composites. Materials. 2015;8:8839–49.

Deorsola FA, Atias Adrian IC, Ortigoz Villalba GA, DeBenedetti B. Nanostructured TiC–TiB2 composites obtained by adding carbon nanotubes into the self-propagating high-temperature synthesis process. Mater Res Bull. 2011;46:995–9.

Filimonov VY, Korchagin MA, Smirnov EV, Sytnikov AA, Yakovlev VI, Lyakhov NZ. Kinetics of mechanically activated high temperature synthesis of Ni3Al in the thermal explosion mode. Intermetallics. 2011;19:833–40.

Korchagin MA. Thermal explosion in mechanically activated low-calorific-value compositions. Combust Explos Shock Waves. 2015;51:578–86.

Korchagin MA, Bulina NV. Superadiabatic regime of the thermal explosion in a mechanically activated mixture of tungsten with carbon black. Combust Explos Shock Waves. 2016;52:225–33.

Mukasyan AS, Rogachev AS. Combustion synthesis: mechanically induced nanostructured materials. J Mater Sci. 2017;52:11826–33.

Mukasyan AS, Rogachev AS, ThippaReddy Aruna S. Combustion synthesis in nanostructured reactive systems. Adv Powder Technol. 2015;26:954–76.

Gabdrashova SE, Rakhova NM, Pustovalov IO, Elemesova Z, Tulepov MI, Korchagin MA, Sassykova LR, Sendilvelan S, Baiseitov DA. Preparation of mechanically activated mixtures of titanium with the carbon nanotubes and study of their properties under thermal explosion. Rasayan J Chem. 2018;11:324–30.

Dudina DV, Pribytkov GA, Krinitcyn MG, Korchagin MA, Bulina NV, Bokhonov BB, Batraev IS, Rybin DK, Ulianitsky VYu. Detonation spraying behavior of TiCx–Ti powders and the role of reactive processes in the coating formation. Ceram Int. 2016;42:690–6.

Arvieu C, Manaud JP, Quenisset JM. Interaction between titanium and carbon at moderate temperatures. J Alloys Compd. 2004;368:116–22.

Munir KS, Li Y, Qian M, Wen C. Identifying and understanding the effect of milling energy on the synthesis of carbon nanotubes reinforced titanium metal matrix composites. Carbon. 2016;99:384–97.

Zhang X, Song F, Wei Z, Yang W, Dai Z. Microstructural and mechanical characterization of in situ TiC/Ti titanium matrix composites fabricated by graphene/Ti sintering reaction. Mater Sci Eng A. 2017;705:153–9.

Saba F, Abdolkarim Sajjadi S, Haddad-Sabzevar M, Zhang F. TiC-modified carbon nanotubes, TiC nanotubes and TiC nanorods: synthesis and characterization. Ceram Int. 2018;44:7949–54.

Acknowledgements

This study was conducted within the state assignment to ISSCM SB RAS (Project AAAA-A17-117030310277-6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Korchagin, M.A., Gabdrashova, S.E., Dudina, D.V. et al. Combustion characteristics and structure of carbon nanotube/titanium composites. J Therm Anal Calorim 137, 1903–1910 (2019). https://doi.org/10.1007/s10973-019-08109-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08109-8