Abstract

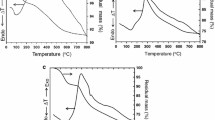

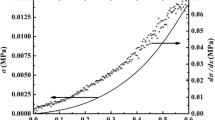

Substantial knowledge gap still exists in understanding Stöber silica’s confusing microporosity. In this work, we utilized simultaneous thermal analysis coupled with Fourier transform infrared spectroscopy to characterize Stöber silica samples prepared with various post-treatments including water or ethanol washing and drying at different temperatures. The results suggest that ammonia-catalyzed ethoxylation between ethanol and silanol groups can take place during drying, and the resulting ethoxyl groups along with Si-containing oligomers may contribute to serious micropore blocking. On the other hand, water washing is effective to hydrolyze and remove these pore-blocking materials and thus enable cleared micropores. Several interesting findings including the very sharp DSC peaks, high evolving temperature of ethanol, and pyrolysis of organic matters are linked to Stöber silica’s micropores. Our work has undoubtedly improved the mechanistic understanding of Stöber silica’s microporosity and will thus facilitate the practical optimization and application of this material.

Similar content being viewed by others

References

Stöber W, Fink A, Bohn E. Controlled growth of monodisperse silica spheres in the micron size range. J Colloids Interface Sci. 1968;26(1):62–9.

Wong YJ, Zhu L, Teo WS, Tan YW, Yang Y, Wang C, et al. Revisiting the Stöber method: inhomogeneity in silica shells. J Am Chem Soc. 2011;133(30):11422–5.

Wang H, Yu M, Lin CK, Lin J. Core–shell structured SiO2@YVO4: Dy3+/Sm3+ phosphor particles: sol–gel preparation and characterization. J Colloids Interface Sci. 2006;300(1):176–82.

Cho S-H, Park SY, Kim C, Choi P-P, Park J-K. Stabilization of monodispersed spherical silica particles and their alignment with reduced crack density. Colloids Surf A Physicochem Eng Asp. 2014;441:354–9.

Diedrich T, Dybowska A, Schott J, Valsarni-Jones E, Oelkers EH. The dissolution rates of SiO2 nanoparticles as a function of particle size. Environ Sci Technol. 2012;46(9):4909–15.

Kim JM, Chang SM, Kong SM, Kim KS, Kim J, Kim WS. Control of hydroxyl group content in silica particle synthesized by the sol-precipitation process. Ceram Int. 2009;35(3):1015–9.

Mueller R, Kammler HK, Wegner K, Pratsinis SE. OH surface density of SiO2 and TiO2 by thermogravimetric analysis. Langmuir. 2003;19(1):160–5.

Bogush GH, Tracy MA, Zukoski CF. Preparation of monodisperse silica particles control of size and mass fraction. J Non-Cryst Solids. 1988;104:95–106.

Giesche H. Synthesis of monodispersed silica powders I. Particle properties and reaction kinetics. J Eur Ceram Soc. 1994;14:189–204.

Wang H-C, Wu C-Y, Chung C-C, Lai M-H, Chung T-W. Analysis of parameters and interaction between parameters in preparation of uniform silicon dioxide nanoparticles using response surface methodology. Ind Eng Chem Res. 2006;45(24):8043–8.

Hartlen KD, Athanasopoulos APT, Kitaev V. Facile preparation of highly monodisperse small silica spheres (15 to > 200 nm) suitable for colloidal templating and formation of ordered arrays. Langmuir. 2008;24(5):1714–20.

Yang M, Wu H, Wu H, Huang C, Weng W, Chen M, et al. Preparation and characterization of a highly dispersed and stable Ni catalyst with a microporous nanosilica support. RSC Adv. 2016;6(84):81237–44.

Yu MH, Niu YT, Zhang J, Zhang HW, Yang YN, Taran E, et al. Size-dependent gene delivery of amine-modified silica nanoparticles. Nano Res. 2016;9(2):291–305.

Szekeres M, Toth J, Dekany I. Specific surface area of Stöber silica determined by various experimental methods. Langmuir. 2002;18(7):2678–85.

Dekany I, Nemeth J, Szekeres M, Schoonheydt R. Surfacial, liquid sorption and monolayer-forming properties of hydrophilic and hydrophobic Stöber silica particles. Colloids Polym Sci. 2003;282(1):1–6.

Howard A, Khdary N. Spray synthesis of monodisperse sub-micron spherical silica particles. Mater Lett. 2007;61(8–9):1951–4.

Davis PJ, Deshpande R, Smith DM, Brinker CJ, Assink RA. Pore structure evolution in silica gel during aging/drying. IV. Varying pore fluid pH. J Non-Cryst Solids. 1994;167(3):295–306.

Filipovic R, Obrenovic Z, Stijepovic I, Nikolic LM, Srdic VV. Synthesis of mesoporous silica particles with controlled pore structure. Ceram Int. 2009;35(8):3347–53.

Li S, Wan Q, Qin Z, Fu Y, Gu Y. Unraveling the mystery of Stöber silica’s microporosity. Langmuir. 2016;32(36):9180–7.

Labrosse A, Burneau A. Characterization of porosity of ammonia catalysed alkoxysilane silica. J Non-Cryst Solids. 1997;221(2–3):107–24.

Wan Q, Ramsey C, Baran G. Thermal pretreatment of silica composite filler materials. J Therm Anal Calorim. 2010;99(1):237–43.

Wells JD, Koopal LK, de Keizer A. Monodisperse, nonporous, spherical silica particles. Colloids Surf A. 2000;166:171–6.

Wang YF. Nanogeochemistry: nanostructures, emergent properties and their control on geochemical reactions and mass transfers. Chem Geol. 2014;378:1–23.

Li S, Wan Q, Qin Z, Fu Y, Gu Y. Understanding Stöber silica’s pore characteristics measured by gas adsorption. Langmuir. 2015;31(2):824–32.

Vanblaaderen A, Vangeest J, Vrij A. Monodisperse colloidal silica spheres from tetraalkoxysilanes: particle formation and growth mechanism. J Colloids Interface Sci. 1992;154(2):481–501.

Huang Y, Pemberton JE. Synthesis of uniform, spherical sub-100 nm silica particles using a conceptual modification of the classic LaMer model. Colloids Surf A. 2010;360(1–3):175–83.

Stefaniak W, Goworek J, Bilinski B. Pore size analysis by nitrogen adsorption and thermal desorption. Colloids Surf A Physicochem Eng Asp. 2003;214(1–3):231–7.

Ma Y, Wang J, Zhang Y. TG-FTIR study on pyrolysis of waste printing paper. J Therm Anal Calorim. 2017;129(2):1225–32.

Macan J, Paljar K, Burmas B, Spehar G, Leskovac M, Gajovic A. Epoxy-matrix composites filled with surface-modified SiO2 nanoparticles. J Therm Anal Calorim. 2017;127(1):399–408.

Catauro M, Naviglio D, Risoluti R, Ciprioti SV. Sol-gel synthesis and thermal behavior of bioactive ferrous citrate-silica hybrid materials. J Therm Anal Calorim. 2018;133(2):1085–92.

Ossenkamp GC, Kemmitt T, Johnston JH. Toward functionalized surfaces through surface esterification of silica. Langmuir. 2002;18(15):5749–54.

Iler RK. The chemistry of silica: solubility, polymerization, colloid and surface properties. New York: Wiley; 1979.

Yariv S, Cross H. Geochemistry of colloid systems for earth scientists. Berlin: Springer; 1979.

Ying JY, Benziger JB, Navrotsky A. Structural evolution of alkoxide silica-gels to glass-effect of catalyst pH. J Am Ceram Soc. 1993;76(10):2571–82.

Mitropoulos AC. The Kelvin equation. J Colloids Interface Sci. 2008;317(2):643–8.

Acknowledgements

The authors gratefully acknowledge support of this work by the National Natural Science Foundation of China (41473064), the Chinese Academy of Sciences (“Hundred Talents Program”), the State Key Laboratory of Ore Deposit Geochemistry (SKLODG-ZY125-09) and the Doctoral Starting up Foundation of Guizhou Normal University, China.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, S., Wan, Q., Qin, Z. et al. Stöber silica’s microporosity. J Therm Anal Calorim 136, 1895–1904 (2019). https://doi.org/10.1007/s10973-018-7850-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7850-2