Abstract

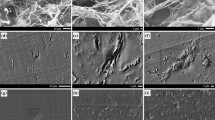

Blends of poly(butylene terephthalate) (PBT) and cellulose acetate propionate (CAP) were found to be immiscible. In order to improve the interfacial strength and miscibility of the PBT/CAP blends, a low-molecular-weight poly(ethylene glycol) (PEG) was thus pre-mixed with the CAP to form the P-CAP mixture. It was then blended with the PBT up to 15 wt% using a twin-screw extruder to prepare the PBT/P-CAP blends, and subsequently processed into the films and fibers by compression-molding and melt-spinning, respectively. The thermal and dynamic mechanical analyses suggested that the PBT and CAP became partially miscible and the interfacial strength was thus improved in the PBT/P-CAP blends, owing to the addition of PEG. The PEG was not only miscible with the CAP but also with the PBT, and it served as a plasticizer as well as a compatibilizer. From the observation of the fractured surface of the PBT/P-CAP films, the PBT component was present as dispersed particles in the P-CAP matrix with size ranging from 1.4 to 3.0 μm; yet it became nanofiber in the spun fibers. Successful fibers of the PBT/P-CAP blends with an average diameter of 20 μm could be spun, where the tensile strength and elongation at break were in the range of 0.6−0.7 g/denier and 12−16%, respectively. Finally, the ultra-fine PBT nanofibers with diameters in the range of 50−70 nm were observed after removing the P-CAP matrix with acetone from the fibers, owing to the formation of PBT nanofibers during spinning and orientation processes. This method thus could successfully produce nano-scale PBT fibers with fineness comparable with the nanofibers developed via electrospinning technology.

Similar content being viewed by others

References

Roy D, Semsarilar M, Guthrie JT, Perrier S (2009) Cellulose modification by polymer grafting: a review. Chem Soc Rev 38:2046–2064

Edgar KJ, Buchanan CM, Debenham JS, Rundquist PA, Seiler BD, Shelton MC, Tindall D (2001) Advances in cellulose ester performance and application. Prog Polym Sci 26:1605–1688

Chen B, Zhong L, Gu L (2010) Thermal properties and chemical changes in blend melt spinning of cellulose acetate butyrate and a novel cationic dyeable copolyester. J Appl Polym Sci 116:2487–2495

Mariastella S, Giuseppina C, Maria P (1992) Miscibility of bacterial poly(3-hydroxybutyrate) with cellulose esters. Macromolecules 25:6441–6446

Buchanan CM, Gedon SC, White AW, Wood MD (1993) Cellulose acetate propionate and poly(tetramethylene glutarate) blends. Macromolecules 26:2963–2967

Shafee EE, Saad GR, Fahmy SM (2001) Miscibility, crystallization and phase structure of poly(3-hydroxybutyrate)/cellulose acetate butyrate blends. Eur Polym J 37:2091–2104

Field ND, Chien MC (1985) Poly(ethylene terephthalate)/cellulose blends. J Appl Polym Sci 30:2105–2113

Wang D, Sun G (2011) Novel polymer blends from polyester and bio-based cellulose ester. J Appl Polym Sci 119:2302–2309

Wang D, Sun G (2007) Formation and morphology of cellulose acetate butyrate (CAB)/polyolefin and CAB/polyester in situ microfibrillar and lamellar hybrid blends. Eur Polym J 43:3587–3596

Li MF, Xiao R, Sun G (2011) Formation and morphology development of poly(butylene terephthalate) nanofibers from poly(butylene terephthalate)/cellulose acetate butyrate immiscible blends. Polym Eng Sci 51:835–842

Nabar YU, Gupta A, Narayan R (2005) Isothermal crystallization kinetics of poly (ethylene terephthalate) – cellulose acetate blends. Polym Bull 53:117–125

Vázquez-Torres H, Cruz-Ramos CA (1994) Blends of cellulosic esters with poly(caprolactone): Characterization by DSC, DMA, and WAXS. J Appl Polym Sci 54:1141–1159

Kusumi R, Inoue Y, Shirakawa M, Miyashita Y, Nishio Y (2008) Cellulose alkyl ester/poly(ε-caprolactone) blends: characterization of miscibility and crystallization behavior. Cellulose 15:1–16

Park JW, Tanaka T, Doi Y, Iwata T (2005) Uniaxial drawing of poly[(R)-3-hydroxybutyrate] /cellulose acetate butyrate blends and their orientation behavior. Macromol Biosci 5:840–852

Uesaka T, Nakane K, Maeda S, Ogihara T, Ogata N (2000) Structure and physical properties of poly(butylene succinate)/cellulose acetate blends. Polymer 41:8449–8454

Mckee MG, Wilkes GL, Colby RH, Long TE (2004) Correlations of solution rheology with electrospun fiber formation of linear and branched polyesters. Macromolecules 37:1760–1767

Dong Y, Liao S, Ngiam M, Chan CK, Ramakrishna S (2009) Degradation behaviors of electrospun resorbable polyester nanofibers. Tissue Eng Part B 15:333–351

Reneker DH, Chun I (1996) Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 7:216–223

Veleirinho B, Rei MF, Lopes-DA-Silva JA (2008) Solvent and concentration effects on the properties of electrospun poly(ethylene terephthalate) nanofiber mats. J Polym Sci B Polym Phys 46:460–471

Liang NY, Don TM, Huang CY, Chiu WY (2017) Fiber and film developments from immiscible blends of cellulose acetate propionate and poly(butylene terephthalate). J Appl Polym Sci 134: app.45013

Kim CH, Kim DW, Cho KY (2009) The influence of PEG molecular weight on the structural changes of corn starch in a starch-PEG blend. Polym Bull 63:91–99

Illers KH (1980) Heat of fusion and specific volume of poly(ethylene terephthalate) and poly(butylene terephthalate). Colloid Polym Sci 258:117–124

Acknowledgements

The authors want to thank Taiwan Textile Research Institute (New Taipei City, Taiwan) for the support of instruments including twin-screw extruder, melt-spinning apparatus, and Dr. Sheng-Shan Chang and Dr. Yi-Ching Sung for their technical assistance.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liang, NY., Don, TM., Huang, CY. et al. Effect of a low-molecular-weight compatibilizer on the immiscible blends of cellulose acetate propionate and poly(butylene terephthalate). J Polym Res 25, 88 (2018). https://doi.org/10.1007/s10965-018-1487-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1487-5