Abstract

Lignin, a cheap renewable natural polymer, can be used as a precursor for the production of carbon fibres, its conversion into which is significantly faster than that of polyacrylonitrile. Lignin can be fractionated in various solvents via dissolution to decrease its polydispersity. Fractions with a higher molecular weight distribution can then be used in solvent-based spinning technologies such as electrospinning. We selected several solvent systems according to the Hansen solubility theory and subsequently tested them for solubility and electro-spinability. The selected solvent systems were then successfully tested for use in the needleless electrospinning process due to their potential for mass production. The solutions used in the electrospinning process needed high concentrations of lignin, which led to a high degree of viscosity. Therefore, we measured the relaxation times and viskosity for selected solutions, a factor that plays a pivotal role in terms of the production of smooth fibres. Finally, these solutions were tested for electrospinning using alternating current. This technology brings a new possibility in mass production of lignin fibres due to its high productivity and ease of use. Such materials can be used in a number of applications such as batteries, supercapacitors or for the production of composite materials. They provide a cheap and renewable natural polymer source which can easily be transformed into a carbon nanofibrous layer.

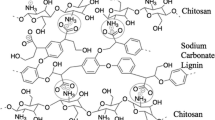

Graphic Abstract

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

Glasser WG, Sarkanen S, American Chemical Society (1989) Lignin: properties and materials. American Chemical Society, Washington, DC

Baker DA, Rials TG (2013) Recent advances in low-cost carbon fiber manufacture from lignin. J Appl Polym Sci 130:713–728. https://doi.org/10.1002/app.39273

Ruiz-Rosas R, Bedia J, Lallave M et al (2010) The production of submicron diameter carbon fibers by the electrospinning of lignin. Carbon 48:696–705. https://doi.org/10.1016/j.carbon.2009.10.014

Ramakrishna S, Fujihara K, Teo W-E et al (2005) An introduction to electrospinning and nanofibers. World Scientific, Singapore

Tolbert A, Akinosho H, Khunsupat R et al (2014) Characterization and analysis of the molecular weight of lignin for biorefining studies. Biofuels BioprodBioref 8:836–856. https://doi.org/10.1002/bbb.1500

Moerck R, Yoshida H, Kringstad KP, Hatakeyama H (1986) Fractionation of kraft lignin by successive extraction with organic solvents. 1. Functional groups (13)C-NMR-spectra and molecular weight distributions. Holzforschung 40:53–58

Rohde V, Böringer S, Tübke B et al (2019) Fractionation of three different lignins by thermal separation techniques-a comparative study. GCB Bioenergy 11:206–217. https://doi.org/10.1111/gcbb.12546

Jääskeläinen A-S, Liitiä T, Mikkelson A, Tamminen T (2017) Aqueous organic solvent fractionation as means to improve lignin homogeneity and purity. Ind Crops Prod 103:51–58. https://doi.org/10.1016/j.indcrop.2017.03.039

Nordström Y, Norberg I, Sjöholm E, Drougge R (2013) A new softening agent for melt spinning of softwood kraft lignin. J Appl Polym Sci 129:1274–1279. https://doi.org/10.1002/app.38795

Kumar M, Hietala M, Oksman K (2019) Lignin-based electrospun carbon nanofibers. Front Mater 6:62. https://doi.org/10.3389/fmats.2019.00062

Schlee P, Herou S, Jervis R et al (2019) Free-standing supercapacitors from Kraft lignin nanofibers with remarkable volumetric energy density. Chem Sci 10:2980–2988. https://doi.org/10.1039/C8SC04936J

Hansen CM (2007) Hansen solubility parameters: a user’s handbook, 2nd edn. CRC Press, Boca Raton

Reneker DH, Yarin AL (2008) Electrospinning jets and polymer nanofibers. Polymer 49:2387–2425. https://doi.org/10.1016/j.polymer.2008.02.002

Lukas D, Sarkar A, Pokorny P (2008) Self-organization of jets in electrospinning from free liquid surface: a generalized approach. J Appl Phys 103:084309. https://doi.org/10.1063/1.2907967

Jirsak O, Sanetrnik F, Lukas D et al. A method of nanofibres production from a polymer solution using electrostatic spinning and a device for carrying out the method

Pokorny P, Kostakova E, Sanetrnik F et al (2014) Effective AC needleless and collectorless electrospinning for yarn production. Phys Chem Chem Phys 16:26816–26822. https://doi.org/10.1039/C4CP04346D

European Medicines Agency TOXICOLOGICAL DATA FOR CLASS 1 SOLVENTS Q3C SUPPORT DOCUMENT 1

Valtera J, Kalous T, Pokorny P et al (2019) Fabrication of dual-functional composite yarns with a nanofibrous envelope using high throughput AC needleless and collectorless electrospinning. Sci Rep 9:1801. https://doi.org/10.1038/s41598-019-38557-z

Rezanowich A, Goring DAI (1960) Polyelectrolyte expansion of a lignin sulfonate microgel. J Colloid Sci 15:452–471. https://doi.org/10.1016/0095-8522(60)90049-0

Costa CN, Teixeira VG, Delpech MC et al (2015) Viscometric study of chitosan solutions in acetic acid/sodium acetate and acetic acid/sodium chloride. Carbohyd Polym 133:245–250. https://doi.org/10.1016/j.carbpol.2015.06.094

Forward KM, Rutledge GC (2012) Free surface electrospinning from a wire electrode. Chem Eng J 183:492–503. https://doi.org/10.1016/j.cej.2011.12.045

Fang W, Yang S, Yuan T-Q et al (2017) Effects of various surfactants on alkali lignin electrospinning ability and spun fibers. IndEngChem Res 56:9551–9559. https://doi.org/10.1021/acs.iecr.7b02494

Balogh A, Farkas B, Verreck G et al (2016) AC and DC electrospinning of hydroxypropylmethylcellulose with polyethylene oxides as secondary polymer for improved drug dissolution. Int J Pharm 505:159–166. https://doi.org/10.1016/j.ijpharm.2016.03.024

Schlee P, Hosseinaei O, Baker D et al (2019) From waste to wealth: from kraft lignin to free-standing supercapacitors. Carbon 145:470–480. https://doi.org/10.1016/j.carbon.2019.01.035

Cho M, Karaaslan M, Wang H, Renneckar S (2018) Greener transformation of lignin into ultralight multifunctional materials. J Mater Chem A 6:20973–20981. https://doi.org/10.1039/C8TA07802E

Liu HC, Chien A-T, Newcomb BA et al (2015) Processing, structure, and properties of lignin- and CNT-incorporated polyacrylonitrile-based carbon fibers. ACS Sustain ChemEng 3:1943–1954. https://doi.org/10.1021/acssuschemeng.5b00562

Roman J, Neri W, Derré A, Poulin P (2019) Electrospun lignin-based twisted carbon nanofibers for potential microelectrodes applications. Carbon 145:556–564. https://doi.org/10.1016/j.carbon.2019.01.036

Jayawickramage RAP, Ferraris JP (2019) High performance supercapacitors using lignin based electrospun carbon nanofiber electrodes in ionic liquid electrolytes. Nanotechnology 30:155402. https://doi.org/10.1088/1361-6528/aafe95

Vivo-Vilches J, Celzard A, Fierro V et al (2019) Lignin-based carbon nanofibers as electrodes for vanadium redox couple electrochemistry. Nanomaterials 9:106. https://doi.org/10.3390/nano9010106

Beck RJ, Zhao Y, Fong H, Menkhaus TJ (2017) Electrospun lignin carbon nanofiber membranes with large pores for highly efficient adsorptive water treatment applications. J Water Process Eng 16:240–248. https://doi.org/10.1016/j.jwpe.2017.02.002

Camiré A, Espinasse J, Chabot B, Lajeunesse A (2018) Development of electrospun lignin nanofibers for the adsorption of pharmaceutical contaminants in wastewater. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-018-3333-z

Acknowledgements

This work was funded by FORMAS (a Swedish research council for sustainable development), the Swedish Energy Agency and companies in the pulp and paper industry within the research project Lignin Value Chain, a part of the Innventia Research Programme 2015-2017.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mikeš, P., Baker, D.A., Uhlin, A. et al. The Mass Production of Lignin Fibres by Means of Needleless Electrospinning. J Polym Environ 29, 2164–2173 (2021). https://doi.org/10.1007/s10924-020-02029-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-02029-7