Abstract

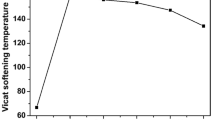

Poly(butylene succinate) (PBS) was melt blended with glycerol based polyesters (PGS) synthesized from pure and technical glycerol aiming to improve the impact strength of PBS. It was found that after addition of 30 wt% PGS to PBS its impact strength was significantly increased by 344% (from 31.9 to 110 J/m) and its elongation at break was maintained at 220%. Infrared spectra of the blends showed the presence of hydroxyl groups from the PGS phase suggesting that hydrogen bonding between the phases could be responsible for a good stress transfer and an efficient toughening in the PBS/PGS blends. Scanning electron microscopy imaging showed a good dispersion of PGS phase into PBS with a PGS particle size of 10 μm and less and no agglomeration. Addition of PGS to PBS was shown to be an effective strategy for improvement of PBS impact resistance without serious detrimental effects on its thermal and rheological properties.

Similar content being viewed by others

References

Reddy MM, Vivekanandhan S, Misra M, et al (2013) Biobased plastics and bionanocomposites: current status and future opportunities. Prog Polym Sci 38:1653–1689. doi:10.1016/j.progpolymsci.2013.05.006

Fujimaki T (1998) Processability and properties of aliphatic polyesters, “BIONOLLE”, synthesized by polycondensation reaction. Polym Degrad Stab 59:209–214. doi:10.1016/S0141-3910(97)00220-6

Gigli M, Fabbri M, Lotti N et al (2016) Poly(butylene succinate)-based polyesters for biomedical applications: a review in memory of our beloved colleague and friend Dr. Lara Finelli. Eur Polym J 75:431–460. doi:10.1016/j.eurpolymj.2016.01.016

Novamont Press Office - Opening Of The World’s First Industrial Scale Plant For The Production Of Butanediol Via Fermentation Of Renewable Raw Materials - Novamont - Press. http://www.novamont.com/eng/read-press-release/mater-biotech/. Accessed 27 Feb 2017

(2015) Cool new materials for durables. Plast Eng Oct Ed 12–17.

(2015) New High Biocontent Biopolymers | Plastics Engineering Blog on WordPress.com. In: http://plasticsengineeringblog.com/2015/09/03/new-high-biocontent-biopolymers/. http://plasticsengineeringblog.com/2015/09/03/new-high-biocontent-biopolymers/. Accessed 17 Feb 2016

Xu J, Guo BH (2010) Poly(butylene succinate) and its copolymers: research, development and industrialization. Biotechnol J 5:1149–1163. doi:10.1002/biot.201000136

Run M, Wang J, Yao M et al (2013) Influences of hyperbranched poly(amide-ester) on the properties of poly(butylene succinate). Mater Chem Phys 139:988–997

Hemsri S, Thongpin C, Moradokpermpoon N, et al (2015) Mechanical properties and thermal stability of poly(butylene succinate)/acrylonitrile butadiene rubber blend. Macromol Symp 354:145–154. doi:10.1002/masy.201400129

Wang J, Zheng L, Li C et al (2012) Fully biodegradable blends of poly(butylene succinate) and poly butylene carbonate): miscibility, thermal properties, crystallization behavior and mechanical properties. Polym Test 31:39–45. doi:10.1016/j.polymertesting.2011.09.005

Muthuraj R, Misra M, Mohanty AK (2015) Hydrolytic degradation of biodegradable polyesters under simulated environmental conditions. J Appl Polym Sci. doi:10.1002/app.42189

Can E, Bucak S, Kınacı E et al (2014) Polybutylene succinate (PBS)–Polycaprolactone (PCL) blends compatibilized with poly(ethylene oxide)- block -poly(propylene oxide)- block -poly(ethylene oxide) (PEO–PPO–PEO) copolymer for biomaterial applications. Polym Plast Technol Eng 53:1178–1193. doi:10.1080/03602559.2014.886119

Ciriminna R, Della PC, Rossi M, Pagliaro M (2014) Understanding the glycerol market. Eur J Lipid Sci Technol 116:1432–1439. doi:10.1002/ejlt.201400229

Ardi MS, Aroua MK, Hashim NA (2015) Progress, prospect and challenges in glycerol purification process: a review. Renew Sustain Energy Rev 42:1164–1173. doi:10.1016/j.rser.2014.10.091

Valerio O, Horvath T, Pond C et al (2015) Improved utilization of crude glycerol from biodiesel industries: synthesis and characterization of sustainable biobased polyesters. Ind Crops Prod 78:141–147. doi:10.1016/j.indcrop.2015.10.019

Valerio O, Pin JM, Misra M, Mohanty AK (2016) Synthesis of glycerol-based biopolyesters as toughness enhancers for polylactic acid bioplastic through reactive extrusion. ACS Omega 1:1284–1295. doi:10.1021/acsomega.6b00325

Pin J-M, Valerio O, Misra M, Mohanty A (2017) Impact of butyl glycidyl ether comonomer on poly(glycerol–succinate) architecture and dynamics for multifunctional hyperbranched polymer design. Macromolecules 50:732–745. doi:10.1021/acs.macromol.6b02424

Bueno L, Toro C, Martín M (2015) Techno-economic evaluation of the production of polyesters from glycerol and adipic acid. Chem Eng Res Des 93:432–440. doi:10.1016/j.cherd.2014.05.010

Valerio O (2014) Synthesis and Use of Glycerol Based Hyperbranched Biopolyesters as Impact Modifiers for Poly (Butylene Succinate) Matrix Dissertation. University of Guelph

Liu H, Song W, Chen F et al (2011) Interaction of microstructure and interfacial adhesion on impact performance of polylactide (PLA) ternary blends. Macromolecules 44:1513–1522. doi:10.1021/ma1026934

Kfoury G, Raquez J-M, Hassouna F et al (2015) Toughening of poly(lactide) using polyethylene glycol methyl ether acrylate: reactive versus physical blending. Polym Eng Sci 55:1408–1419. doi:10.1002/pen.24085

Signori F, Boggioni A, Righetti MC, et al (2015) Evidences of transesterification, chain branching and cross-linking in a biopolyester commercial blend upon reaction with dicumyl peroxide in the melt. Macromol Mater Eng 300:153–160. doi:10.1002/mame.201400187

Li X, Hong AT-L, Naskar N, Chung H-J (2015) Criteria for quick and consistent synthesis of poly(glycerol sebacate) for tailored mechanical properties. Biomacromolecules 16:1525–1533. doi:10.1021/acs.biomac.5b00018

Li Y, Cook WD, Moorhoff C, et al (2013) Synthesis, characterization and properties of biocompatible poly(glycerol sebacate) pre-polymer and gel. Polym Int 62:534–547. doi:10.1002/pi.4419

Brioude M de M, Guimarães DH, Fiúza R da P, et al (2007) Synthesis and characterization of aliphatic polyesters from glycerol, by-product of biodiesel production, and adipic acid. Mater Res 10:335–339.

Tang J, Zhang Z, Song Z et al (2006) Synthesis and characterization of elastic aliphatic polyesters from sebacic acid, glycol and glycerol. Eur Polym J 42:3360–3366. doi:10.1016/j.eurpolymj.2006.09.008

Lin Y, Zhang K-Y, Dong Z-M et al (2007) Study of hydrogen-bonded blend of polylactide with biodegradable hyperbranched poly(ester amide). Macromolecules 40:6257–6267. doi:10.1021/ma070989a

Perkins WG (1999) Polymer toughness and impact resistance. Polym Eng Sci 39:2445–2460. doi:10.1002/pen.11632

Muthuraj R, Misra M, Mohanty AK (2014) Biodegradable poly(butylene succinate) and poly(butylene adipate-co-terephthalate) blends: reactive extrusion and performance evaluation. J Polym Environ 22:336–349. doi:10.1007/s10924-013-0636-5

Wyatt VT, Jones K (2012) Quantification of monomers in poly(glycerol-co-diacid) gels using gas chromatography. J Biobased Mater Bioenergy 6:119–124. doi:10.1166/jbmb.2012.1189

Stumbé JF, Bruchmann B (2004) Hyperbranched polyesters based on adipic acid and glycerol. Macromol Rapid Commun 25:921–924. doi:10.1002/marc.200300298

Pongtanayut K, Thongpin C, Santawitee O (2013) The effect of rubber on morphology, thermal properties and mechanical properties of PLA/NR and PLA/ENR blends. Energy Procedia 34:888–897. doi:10.1016/j.egypro.2013.06.826

Ishida S, Nagasaki R, Chino K et al (2009) Toughening of poly(l-lactide) by melt blending with rubbers. J Appl Polym Sci 113:558–566. doi:10.1002/app.30134

Qiu Z, Ikehara T, Nishi T (2003) Melting behaviour of poly(butylene succinate) in miscible blends with poly(ethylene oxide). Polymer 44:3095–3099. doi:10.1016/S0032-3861(03)00216-7

Qiu Z, Komura M, Ikehara T, Nishi T (2003) DSC and TMDSC study of melting behaviour of poly(butylene succinate) and poly(ethylene succinate). Polymer 44:7781–7785. doi:10.1016/j.polymer.2003.10.045

Yasuniwa M, Satou T (2002) Multiple melting behavior of poly(butylene succinate). I. Thermal analysis of melt-crystallized samples. J Polym Sci Part B Polym Phys 40:2411–2420. doi:10.1002/polb.10298

Zhou W, Yuan S, Chen Y, Bao L (2012) Morphology and hydrogen-bond restricted crystallization of poly(butylene succinate)/cellulose diacetate blends. J Appl Polym Sci 124:3124–3131. doi:10.1002/app.35351

Kozlowski M, Bucknall CB (2001) Blends containing core-shell impact modifiers Part 2. Melt rheology of rubber-toughened plastics (IUPAC Technical Report). Pure Appl Chem 73:913–926. doi:10.1351/pac200173060913

Acknowledgements

The authors are thankful to the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), Canada/University of Guelph-Bioeconomy for Industrial Uses Research Program Theme (Project # 200001 and 200283); OMAFRA, Canada New Directions Project # 050155; the Ontario Ministry of Economic Development and Innovation (MEDI), Canada, Ontario Research Fund, Research Excellence Round 4 Program (ORF-RE04) (Project # 050231 and 050289); the Natural Sciences and Engineering Research Council (NSERC), Canada - Discovery Grants (Project # 401111) for the financial support to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Valerio, O., Misra, M. & Mohanty, A.K. Improvement of Impact Toughness of Biodegradable Poly(butylene succinate) by Melt Blending with Sustainable Biobased Glycerol Elastomers. J Polym Environ 26, 1078–1087 (2018). https://doi.org/10.1007/s10924-017-1015-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1015-4