Abstract

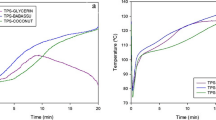

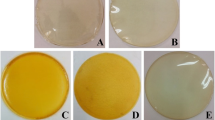

Melt extrusion was used to obtain thermoplastic corn gluten meal (tCGM) blends from plasticized corn gluten meal (pCGM) and poly(butylene adipate-co-terephthalate) (PBAT). Dynamic rheological tests, morphology and spectroscopy were employed to understand the effect of the plasticization and destructurization of corn gluten meal (CGM) on tCGM blends. Rheological data showed a plateau in the low frequencies for tCGM blends demonstrating network formation which responds elastically over long timescales. Also, complex viscosity data showed the existing of shear thinning for PBAT and PBAT–CGM blend. Furthermore, rheology and morphology showed the synergistic influence of plasticization and destructuralization of CGM on the phase structure development of the blends. In addition, it was found for unmodified CGM–PBAT blend there was significant frequency dependence for G′ indicating it just acted as filler for PBAT matrix. FTIR studies showed that the urea has helped in unfolding the corn protein and facilitated hydrogen bonding interactions with PBAT. Tensile properties showed an improvement in tCGM blends when compared unmodified CGM blend. Tensile strength of tCGM blends was almost same as that of the neat PBAT matrix. Percent elongation, a strong reflection of the state of interface in the blends has showed higher values, indicating strong interactions between the PBAT and pCGM in the blend system.

Similar content being viewed by others

Reference

Paetau I, Chen CZ, Jane J (1821) Ind Eng Chem Res 1994:33

Manamperi WAR, Chang SKC, Ulven CA, Pryor SW (2010) J Am Oil Chem Soc 87:909

Di Gioia L, Guilbert S (1999) J Agric Food Chem 47:1254

Verbeek CJR, van den Berg LE (2011) J Polym Environ 19:1

Graiver D, Waikul L, Berger C, Narayan R (2004) J Appl Polym Sci 92:3231

Reddy MM, Mohanty AK, Misra M (2012) J Mater Sci 47:2591

Shukla R, Cheryan M (2001) Ind Crops Prod 13:171

Wang Y, Padua GW (2004) J Agric Food Chem 52:3100

Pickering KL, Verbeek CJR, Viljoen C (2012) J Polym Environ 20:335

Verbeek CJR, Van Den Berg LE (2010) Macromol Mater Eng 295:10

Reddy M, Mohanty AK, Misra M (2010) J Biobased Mater Bioenerg 4:298

De Graaf LA (2000) J Biotechnol 79:299

Di Gioia L, Cuq B, Guilbert S (1999) Macromol Symp 144:365

Di Gioia L, Cuq B, Guilbert S (1998) Cereal Chem 75:514

Aithani D, Mohanty AK (2006) Ind Eng Chem Res 45:6147

Chen F, Zhang J (2010) ACS Appl Mater Interfaces 2:3324

Mannheim A, Cheryan M (1992) J Am Oil Chem Soc 69:1163

Krimm S, Bandekar J (1986) Vibrational spectroscopy and conformation of peptides and proteins. In: Anfinsen CB, Edsall JT, Richards FM (eds) Adv Protein Chem. Academic, Salt Lake City

Yue H, Cui Y, Shuttleworth PS, Clark J (2009) Green Chem 2009:14

Srisa-Ard M, Baimark Y, Srisuwan Y (2008) J Appl Sci 8:3518

Utracki LA (1989) Polymer alloys and blends: thermodynamics and rheology. Hanser Gardner Publications, New York, p 356

Miao D, Qiang Z, Mei YH (2003) Nihon Reoroji Gakkaishi 31:305

Zheng Q, Cao Y, Du M (1813) J Mater Sci 2004:39

Chen F, Zhang J (2009) Polymer 50:3770

Shenoy AV (1999) Rheology of filled polymer systems. Berlin, Springer

Utracki L (1987) Carl Hanser Verlag. Curr Top Polym Sci 2:7

Kota AK, Cipriano BH, Duesterberg MK, Gershon AL, Powell D, Raghavan SR, Bruck HA (2007) Macromolecules 40:7400

Winter H (1987) Polym Eng Sci 27:1698

Thomas S, Groeninckx G (1999) Polymer 40:5799

Everaert V, Aerts L, Groeninckx G (1999) Polymer 40:6627

Rodriguez-Gonzalez F, Ramsay B, Favis B (2003) Polymer 44:1517

Danesi S, Porter RS (1978) Polymer 19:448

Reddy MM, Mohanty AK, Misra M (2012) Macromol Mater Eng 297:455

Favis B, Chalifoux J (1988) Polymer 29:1761

Favis B (2000) Polymer blends. Vol. 1: formulation. New York, Wiley

Tucker CL III, Moldenaers P (2002) Annu Rev Fluid Mech 34:177

Dacko P, Kowalczuk M, Janeczek H, Sobota M (2006) Macromol Symp 239:209

Quintens D, Groeninckx G, Guest M, Aerts L (1990) Polym Eng Sci 30:1474

Huneault MA, Li H (2007) Polymer 48:270

Li G, Favis BD (2010) Macromol Chem Phys 211:321

Acknowledgments

This research is financially supported by the Ontario Ministry of Agriculture and Food and the Ministry of Rural Affairs (OMAF-MRA)/University of Guelph—Bioeconomy for Industrial Uses Research Program; OMAF-MRA New Directions and Alternative Renewable Fuels ‘Plus’ Research Program and Ontario research fund, research excellence, round-4 (ORF RE04) from Ontario ministry of economic development and innovation (MEDI).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Reddy, M.M., Misra, M. & Mohanty, A.K. Biodegradable Blends from Corn Gluten Meal and Poly(butylene adipate-co-terephthalate) (PBAT): Studies on the Influence of Plasticization and Destructurization on Rheology, Tensile Properties and Interfacial Interactions. J Polym Environ 22, 167–175 (2014). https://doi.org/10.1007/s10924-014-0640-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-014-0640-4