Abstract

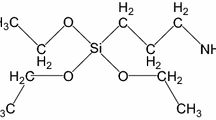

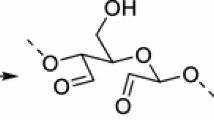

Polylactic acid (PLA)—maple fibre composites have been synthesised using a series of sequentially modified cellulose fibres (namely alkylation followed by either acetylation or silanation). Confirmations of the sequential modifications were made using Fourier Transform Infrared Spectroscopy and Inductively Coupled Plasma—Atomic Emission Spectroscopy and the new surface morphologies analysed using Scanning Electron Microscopy. The key advantage of the use of sequential treatments (with initial alkali treatment) was the allowance for direct grafting of suitable chemical groups onto the cellulose in the fibre due to the removal of lignin, hemicellulose and other surface impurities. However, a balance was found to exist between alkali exposure time, concentration and resulting fibre integrity. The conditions used resulted in a loss in fibre weight, fibre moisture content and tensile strength. Sequential treatments with acetylation or silane resulted in a 15–21% strength recovery from that of the alkali treated composite. Factors that influenced this recovery in strength were the improved fibre-polymer interface, namely the hydrophilic balancing of the fibres and this further affected the thermal-hydrolysis of the PLA during composite fabrication.

Similar content being viewed by others

References

Mohanty AK, Misra M, Drzal LT (2002) J Polym Environ 10:19–26

Mohanty AK, Misra M, Drzal LT (2001) Compos Interfaces 8:313–343

John MJ, Thomas S (2008) Carbohydr Polym 71:343–364

Mohanty AK, Misra M, Hinrichsen G (2000) Macromol Mater Eng 276–277:1–24

Bledzki AK, Gassan J (1999) Prog Polym Sci 24:221–274

Gauthier R, Joly C, Coupas AC, Gauthier H, Escoubes M (1998) Polym Compos 19:287–300

Mohanty AK, Khan MA, Hinrichsen G (2000) Compos Sci Technol 60:1115–1124

Mishra S, Misra M, Tripathy SS, Nayak SK, Mohanty AK (2002) Polym Compos 23:164–170

Mohanty AK, Khan MA, Hinrichsen G (2000) Composites Part A 31:143–150

Hill CAS, Abdul Khalil HPS (2000) J Appl Polym Sci 77:1322–1330

Hill CAS, Abdul Khalil HPS (2000) J Appl Polym Sci 78:1685–1697

Razera IAT, Frollini E (2004) J Appl Polym Sci 91:1077–1085

Tserki V, Matzinos P, Panayiotou C (2003) J Appl Polym Sci 88:1825–1835

Tserki V, Matzinos P, Panayiotou C (2006) Composites Part A 37:1231–1238

Tserki V, Matzinos P, Zafeiropoulos NE, Panayiotou C (2006) J Appl Polym Sci 100:4703–4710

Kushwaha P, Kumar R (2010) J Reinf Plast Compos 29:718–724

Kushwaha PK, Kumar R (2010) J Appl Polym Sci 115:1846–1852

Huda MS, Drzal LT, Mohanty AK, Misra M (2008) Compos Interfaces 15:169–191

Huda MS, Drzal LT, Mohanty AK, Misra M (2008) Compos Sci Technol 68:424–432

Pothan LA, Thomas S (2003) Compos Sci Technol 63:1231–1240

Pilla S, Gong S, O’Neill E, Rowell RM, Krzysik AM (2008) Polym Eng Sci 48:578–587

Shanks RA, Hodzic A, Wong S (2004) J Appl Polym Sci 91:2114–2121

Colom X, Carrasco F, Pagès P, Cañavate J (2003) Compos Sci Technol 63:161–169

Pietak A, Korte S, Tan E, Downard A, Staiger MP (2007) Appl Surf Sci 253:3627–3635

Mishra S, Tripathy SS, Misra M, Mohanty AK, Nayak SK (2002) J Reinf Plast Compos 21:55–70

Garlotta D (2001) J Polym Environ 9:63–84

Raya SS, Yamada K, Okamoto M, Ueda K (2003) Polymer 44:857–866

Tserki V, Matzinos P, Kokkou S, Panayiotou C (2005) Composites Part A 36:965–974

Ray D, Sarkar BK (2001) J Appl Polym Sci 80:1013–1020

Herrera-Franco PJ, Valadez-González A (2005) Composites Part B 36:597–608

Chow P, Nakayama FS, Blahnik B, Youngquist JA, Coffelt TA (2008) Ind Crop Prod 28:303–308

Fengel D, Wegener G (1989) Wood chemistry, ultrastructure, reactions. Walter de Gruyter, Berlin

Sydenstricker THD, Mochnaz S, Amico SC (2003) Polym Test 22:375–380

Wielage B, Lampke T, Marx G, Nestler K, Starke D (1999) Thermochim Acta 337:169–177

Shafizadeh F, Bradbury AGW (1979) J Build Phys 2:141–152

Kushwaha P, Kumar R (2009) J Reinf Plast Compos 28:2851–2859

Cao Y, Shibata S, Fukumoto I (2006) Composites Part A 37:423–429

Lopattananon N, Payae Y, Seadan M (2008) J Appl Polym Sci 110:433–443

Abdul Khalil HPS, Issam AM, Ahmad Shakri MT, Suriani R, Awang AY (2007) Ind Crop Prod 26:315–323

Tokoro R, Vu DM, Okubo K, Tanaka T, Fujii T, Fujiura T (2008) J Mater Sci 43:775–787

Martin O, Averous L (2001) Polymer 42:6209–6219

Kulinski Z, Piorkowska E (2005) Polymer 46:10290–10300

Acknowledgments

The authors of this paper would like to acknowledge the help provided by Mark Greaves (CSIRO—Materials Science and Engineering, Clayton VIC) and Matt Glenn (CSIRO—Minerals, Clayton VIC) in operating their SEMs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Way, C., Dean, K., Wu, D.Y. et al. Polylactic Acid Composites Utilising Sequential Surface Treatments of Lignocellulose: Chemistry, Morphology and Properties. J Polym Environ 19, 849–862 (2011). https://doi.org/10.1007/s10924-011-0361-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-011-0361-x