Abstract

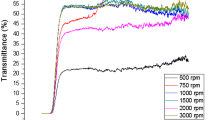

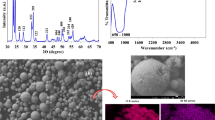

Zinc oxide microflower thin films were deposited in a single-step process using cost-effective ultrasonic spray pyrolysis technique. Different molarity of precursor solution was used to grow the films. X-ray diffraction and Raman spectroscopy reveal the wurtzite structure of ZnO. Scanning electron microscope images showed the microflower morphology which has a better surface to volume ratio. Defects such as O interstitial and Zn vacancy were identified in these thin films with the help of photoluminescence (PL) spectroscopy. The contact angle of the films was found to decrease with increase in molarity of the precursor. Photocatalytic activity of three different molar samples (0.05, 0.1 and 0.15 M) of ZnO were studied for methylene blue (MB) degradation and 0.15 M film demonstrated better degradation efficiency under UV–Vis light. Further degradation studies were performed on this film under exposure to natural sunlight. 90% degradation of the dye was observed in both the conditions upon exposure of 3.5 h. Effect of defects, molarity, bandgap and contact angle of ZnO on the photocatalytic performance is discussed. Repeatability studies performed under both UV–Vis and natural sunlight exposures showed only a minor deviation of 1% from the initial degradation efficiency.

Similar content being viewed by others

References

H. Zollinger, Color Chemistry. Synthesis, Properties and Applications of Organic Dyes and Pigments (Angewandte Chemie International Edition, Hoboken, 2004)

A.R. Khataee, M.B. Kasiri, J. Mol. Catal. A 328, 8–26 (2010)

Y. Zhang, B. Wu, H. Xu, H. Liu, M. Wang, Y. He, B. Pan, NanoImpact. 3–4, 22–39 (2016). https://doi.org/10.1016/j.impact.2016.09.004

O. Legrini, E. Oliveros, A.M. Braun, Chem. Rev. 93, 671–698 (1993)

X. Liang, D. Fu, R. Liu, Q. Zhang, T.Y. Zhang, X. Hu, Angew. Chem. 44, 5520–5523 (2005)

N. Daneshvar, A.R. Khataee, A.R. Amani Ghadim, M.H. Rasoulifard, J. Hazardous Mater. 148, 566–572 (2007)

M.K. Singha, A. Patra, V. Rojwal, K.G. Deepa, D. Kumar, AIP Conf. Proc. (2019). https://doi.org/10.1063/1.5093841

Y. Huang, D. Ding, M. Zhu, W. Meng, Y. Huang, F. Geng, J. Li, J. Lin, C. Tang, Z. Lei, Z. Zhang, C. Zhi, Sci. Technol. Adv. Mater. (2015). https://doi.org/10.1088/1468-6996/16/1/014801

I.M. Szilágyi, B. Fórizs, O. Rosseler, Á. Szegedi, P. Németh, P. Király, G. Tárkányi, B. Vajna, K. Varga-Josepovits, K. László, A.L. Tóth, P. Baranyai, M. Leskelä, J. Catal. 294, 119–127 (2012). https://doi.org/10.1016/j.jcat.2012.07.013

W. Zhang, J. Liu, Z. Guo, S. Yao, H. Wang, J. Mater. Sci. 28, 9505–9513 (2017). https://doi.org/10.1007/s10854-017-6694-z

C.B. Ong, L.Y. Ng, A.W. Mohammad, Renew. Sustain. Energy Rev. 81, 536–551 (2018)

W. Liu, J. Wu, Y. Yang, H. Yu, X. Dong, X. Wang, Z. Liu, T. Wang, B. Zhao, J. Mater. Sci. 29, 4624–4631 (2018). https://doi.org/10.1007/s10854-017-8413-1

L. Han, J. Chen, Y. Zhang, Y. Liu, L. Zhang, Mater. Lett. 210, 8–11 (2018). https://doi.org/10.1016/j.matlet.2017.08.065

B.J. Rani, A. Anusiya, M. Praveenkumar, S. Ravichandran, R.K. Guduru, G. Ravi, R. Yuvakkumar, J. Mater. Sci. 30, 731–745 (2019)

L. Du, Y. Li, S. Li, H. Li, L. Liu, Y. Cheng, H. Duan, J. Mater. Sci. 29, 244–250 (2018)

P.S. Chauhan, A. Rai, A. Gupta, S. Bhattacharya, Mater. Res. Express. 4, 055004 (2017). https://doi.org/10.1088/2053-1591/aa6d31

M.A. Khan, M.K. Singha, K.K. Nanda, S.B. Krupanidhi, Appl. Surf. Sci. 505, 144365 (2020)

M. Marie, S. Mandal, O. Manasreh, Sensors 15, 18714–18723 (2015)

J. Chen, W. Lei, W. Chai, Z. Zhang, C. Li, X. Zhang, Solid-State Electron. 52, 294–298 (2008)

M.K. Singha, A. Patra, IEEE Sensors Appl. Symp. 2019, 1–4 (2019). https://doi.org/10.1109/SAS.2019.8705997

M.-W. Ahn, K.-S. Park, J.-H. Heo, D.-W. Kim, K.J. Choi, J.-G. Park, Sens. Actuators B 138, 168–173 (2009)

J. Zhao, L. Hu, Z. Wang, Z. Wang, H. Zhang, Y. Zhao, X. Liang, J. Cryst. Growth 280, 455–461 (2005)

C. Vargas-Hernández, F.N. Jiménez-García, J.F. Jurado, V. HenaoGranada, Microelectr. J. 39, 1349–1350 (2008)

O.A. Fouad, A.A. Ismail, Z.I. Zaki, R.M. Mohamed, Appl. Catal. B 62, 144–149 (2006)

F. Fleischhaker, V. Wloka, I. Hennig, J. Mater. Chem. 20, 6622–6625 (2010)

B. Hahn, G. Heindel, E. Pschorr-Schoberer, W. Gebhardt, Semicond. Sci. Technol. 13, 788 (1998)

H.J. Ko, Y. Chen, S.K. Hong, T. Yao, J. Cryst. Growth 209, 816–821 (2000)

M.K. Singha, A. Patra, Opt. Mater. 107, 110000 (2020)

S. BenYahia, L. Znaidi, A. Kanaev, J.P. Petitet, Spectrochim. Acta 71, 1234–1238 (2008)

R. Zhang, P.G. Yin, N. Wang, L. Guo, Solid State Sci. 11, 865–869 (2009)

M.K. Singha, K.G. Deepa, Band Gap Tailoring and Raman Studies of Mn Doped ZnO Thin Film Deposited by Ultrasonic Spray Pyrolysis (Springer, Cham, 2019), pp. 535–540

V.A. Nikitenko, V.G. Plekhanov, S.V. Mukhin, M.V. Tkachev, J. Appl. Spectrosc. 63, 290–292 (2007). https://doi.org/10.1007/bf02606743

Y. Huang, M. Liu, Z. Li, Y. Zeng, S. Liu, Mater. Sci. Eng. B 97, 111–116 (2003). https://doi.org/10.1016/S0921-5107(02)00396-3

F. Decremps, J. Pellicer-Porres, A.M. Saitta, J.C. Chervin, A. Polian, Phys. Rev. B 65, 921011–921014 (2002)

J.N. Zeng, J.K. Low, Z.M. Ren, T. Liew, Y.F. Lu, Appl. Surf. Sci. 197–198, 362–367 (2002)

A.K. Ojha, M. Srivastava, S. Kumar, R. Hassanein, J. Singh, M.K. Singh, A. Materny, Vib. Spectrosc. 72, 90–96 (2014). https://doi.org/10.1016/j.vibspec.2014.02.013

R.P. Wang, G. Xu, P. Jin, Phys. Rev. B 69, 5–8 (2004). https://doi.org/10.1103/PhysRevB.69.113303

J. Rouhi, M. Alimanesh, S. Mahmud, R.A. Dalvand, C.H.R. Ooi, M. Rusop, Mater. Lett. 125, 147–150 (2014)

M.F. Malek, M.H. Mamat, Z. Khusaimi, M.Z. Sahdan, M.Z. Musa, A.R. Zainun, A.B. Suriani, N.D.M. Sin, S.B.A. Hamid, M. Rusop, J. Alloy. Compd. 582, 12–21 (2014)

G.Z. Xing, B. Yao, C.X. Cong, T. Yang, Y.P. Xie, B.H. Li, D.Z. Shen, Effect of annealing on conductivity behavior of undoped zinc oxide prepared by rf magnetron sputtering. J. Alloy. Compd. 457, 36–41 (2008)

Ü. Özgür, Y.I. Alivov, C. Liu, A. Teke, M.A. Reshchikov, S. Doǧan, V. Avrutin, S.J. Cho, J. Appl. Phys. 98, 1–103 (2005)

S.A. Studenikin, N. Golego, M. Cocivera, J. Appl. Phys. 84, 2287–2294 (1998)

M. Jiang, D.D. Wang, B. Zou, Z.Q. Chen, A. Kawasuso, T. Sekiguchi, Physica Status Solidi (A) 209, 2126–2130 (2012)

D.P. Mechanisms, D.C. Reynolds, P. Air, F. Base, Science 101, 643–646 (1997)

M. Ghosh, A.K. Raychaudhuri, Nanotechnology. 19, 445704 (2008)

X.L. Xu, S.P. Lau, J.S. Chen, G.Y. Chen, B.K. Tay, J. Cryst. Growth 223, 201–205 (2001)

M. Shaban, M. Zayed, H. Hamdy, RSC Adv. 7, 617–631 (2017)

P. Jongnavakit, P. Amornpitoksuk, S. Suwanboon, T. Ratana, Thin Solid Films 520, 5561–5567 (2012)

J. Zhang, W. Huang, Y. Han, Langmuir 22, 2946–2950 (2006)

J. Bico, C. Tordeux, D. Quere, Europhys. Lett. 55, 214–220 (2001)

A. Riaz, A. Ashraf, H. Taimoor, S. Javed, M.A. Akram, M. Islam, M. Mujahid, I. Ahmad, K. Saeed, Coatings 9, 202–216 (2019)

X. Guo, Q. Zhao, R. Li, H. Pan, X. Guo, A. Yin, W. Dai, Opt. Express. 18, 18401 (2010)

L. Xu, G. Zheng, F. Xian, J. Su, Mater. Chem. Phys. 229, 215–225 (2019)

N.M. Flores, U. Pal, R. Galeazzi, A. Sandoval, RSC Adv. 4, 41099–41110 (2014)

Y. Zheng, C. Chen, Y. Zhan, X. Lin, Q. Zheng, K. Wei, J. Zhu, Y. Zhu, Inorg. Chem. 46, 6675–6682 (2007). https://doi.org/10.1021/ic062394m

R. Ahumada-Lazo, L.M. Torres-Martínez, M.A. Ruíz-Gómez, O.E. Vega-Becerra, M.Z. Figueroa-Torres, Appl. Surf. Sci. 322, 35–40 (2014). https://doi.org/10.1016/j.apsusc.2014.10.049

A.A. Aal, S.A. Mahmoud, A.K. Aboul-Gheit, Mater. Sci. Eng. C 29, 831–835 (2009). https://doi.org/10.1016/j.msec.2008.07.035

Acknowledgements

Authors would like to acknowledge MNFC, CENSE, IISc Bangalore for providing characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Singha, M.K., Patra, A., Rojwal, V. et al. Single-step fabrication of ZnO microflower thin films for highly efficient and reusable photocatalytic activity. J Mater Sci: Mater Electron 31, 13578–13587 (2020). https://doi.org/10.1007/s10854-020-03914-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03914-6