Abstract

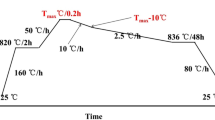

Precursor powders for the fabrication of Bi2Sr2Ca2Cu3O10+δ (Bi-2223) tapes were fabricated with spray drying technique combined with a one-step calcination process. During the spray drying process, the effects of spray temperature on both the morphology and carbon content of collected powders were systematically analyzed. And the uniformity of chemical composition of these powders was confirmed with EDX mapping. By optimizing the calcination temperature, precursor powders with the major phases of Bi2Sr2CaCu2O8+δ (Bi-2212) and alkali earth cuprates (AEC, (Ca, Sr)xCuyOz), proper Pb content, and uniform morphology were obtained. Powder in tube process was adopted for the fabrication of 37-filament Bi-2223 tapes and a traditional heat treatment process involving the first heat treatment, intermediate rolling and second heat treatment was performed, during which textured Bi-2223 phase was obtained. With the optimized fabrication parameters and spray dried precursor powders, 37-filament Bi-2223 tape was achieved with high critical current of I c ~ 125 A. Further optimization involving with the over-pressure heat treatment process is on the way.

Similar content being viewed by others

References

H. Maeda, Y. Tanaka, M. Fukutomi, T. Asano, Jpn. J. Appl. Phys. 27, L209 (1988)

M. Hamabe, M. Sugino, H. Watanabe, T. Kwahara, S. Yamaguchi, Y. Ishiguro, K. Kawamura, IEEE Trans. Appl. Supercond. 21, 1038–1041 (2011)

Y. Yanagisawa, Y. Xu, S. Iguchi, M. Hamada, S. Matsumoto, G. Nishijima, H. Nakagome, T. Takao, H. Suematsu, Y. Oshima, X. Jin, M. Takahashi, H. Maeda, Supercond. Sci. Technol. 28, 125005 (2015)

M. Ohya, Y. Inagaki, K. Tatamidani, H. Ito, T. Saito, Y. Ashibe, M. Watanabe, H. Yumura, T. Nakanishi, H. Hirota, T. Masuda, M. Hirose, R. Ono, M. Shimoda, N. Nakamura, H. Yaguchi, H. Ichikawa, T. Mimura, S. Honjo, T. Hara, SEI Tech. Rev. 76, 45–54 (2013)

Q.Y. Hu, H.K. Liu, S.X. Dou, Phys. C 274, 204–208 (1997)

X.P. Chen, X.W. Yu, R. Xiao, M.Y. Li, Z. Han, J. Alloys Compd. 509, 1090–1093 (2010)

M.H. Pu, Y. Feng, P.X. Zhang, L. Zhou, J.X. Wang, Y.P. Sun, J.J. Du, Phys. C 386, 41–46 (2003)

L. Hua, J. Yoo, J. Ko, H. Kim, H. Chung, G.W. Qiao, Phys. C 291, 149–154 (1997)

Y.C. Guo, Y. Tanaka, T. Kuroda, S.X. Dou, Z.Q. Yang, Phys. C 311, 65–74 (1999)

X. Ma, Q. Hao, G. Liu, H. Zheng, X. Xu, G. Jiao, S. Zhang, C. Li, Mater. Lett. 162, 5–8 (2016)

X.M. Xiong, Z.M. Yu, H.L. Zheng, X.Y. Xu, F.S. Liu, P. Ji, C.S. Li, Y.F. Lu, P.X. Zhang, L. Zhou, Chin. J. Low Temp. Phys. 27, 807–811 (2005)

N. Darsono, A. Imaduddin, K. Raju, D.H. Yoon, J. Supercond. Nov. Magn. 28, 2259–2266 (2015)

R. Bao, X.H. Song, S.S. Chen, H.B. Sun, K. Shi, K. Huang, Z.H. Han, IEEE Trans. Appl. Supercond. 23, 6400704 (2013)

J.W. Ko, J.M. Yoo, Y.K. Kim, K.H. Oh, S.J. Choe, H. Chung, Cryogenics 4, 549–553 (2003)

B.A. Marinkovic, P.M. Jardim, F. Rizzo, L. Mancic, O. Milosevic, Mater. Chem. Phys. 94, 233–240 (2005)

J.M. Yoo, S.W. Kim, J.W. Ko, Y.K. Kim, Supercond. Sci. Technol. 17, S538–S542 (2004)

Acknowledgments

This research was financially supported by National Natural Science Foundation of China under Contract No. 51472206, National ITER Program of China No. 2015GB115001, Natural Science Foundation of Shaanxi Province No. 2016JM5018, and the Program for Innovative Research Team in Shaanxi Province No. 2013KCT-07.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bai, L., Zhang, S., Li, C. et al. Optimization of spray drying process for Bi-2223 precursor powders fabrication. J Mater Sci: Mater Electron 27, 8862–8868 (2016). https://doi.org/10.1007/s10854-016-4977-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4977-4