Abstract

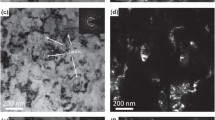

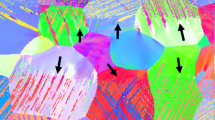

The grain boundary character distribution (GBCD) of a 100-nm-thick Al thin film was measured as a function of annealing time by transmission electron microscopy-based crystal orientation mapping and compared to a bulk material with a grain size of 23 μm. The most significant difference between the thin film and bulk GBCDs is the concentration of Σ3 boundaries (boundaries with a misorientation of 60° around [111]), which were mostly coherent twins. The length fraction of Σ3 boundaries in the as-deposited thin film is 0.245, more than ten times the length fraction in the bulk sample (0.016). Although the concentrations of Σ3 boundaries are very different in the two samples, the population distributions are strongly correlated for all misorientations except Σ3. The results indicate that the characteristic GBCD develops at grain sizes as small as 109 nm. Annealing the thin film samples at 400 °C for 30 min or more leads to a strong 〈111〉 grain orientation texture and a decrease in the concentration of Σ3 grain boundaries. Grain size distributions for the samples in the current study show good agreement with prior reports that used image-based methods.

Similar content being viewed by others

References

Kim CS, Rollett AD, Rohrer GS (2006) Grain boundary planes: new dimensions in the grain boundary character distribution. Scripta Mater 54:1005–1009. doi:10.1016/j.scriptamat.2005.11.071

Lee SB, Key TS, Liang Z et al (2013) Microstructure design of lead-free piezoelectric ceramics. J Eur Ceram Soc 33:313–326. doi:10.1016/j.jeurceramsoc.2012.08.015

Lu L, Shen YF, Chen XH, Qian LH, Lu K (2004) Ultrahigh strength and high electrical conductivity in copper. Science 304:422–426. doi:10.1126/science.1092905

Randle V (2004) Twinning-related grain boundary engineering. Acta Mater 52:4067–4081. doi:10.1016/j.actamat.2004.05.031

Sun T, Yao B, Warren AP et al (2010) Surface and grain-boundary scattering in nanometric cu films. Phys Rev B. doi:10.1103/PhysRevB.81.155454

Adams BL, Wright SI, Kunze K (1993) Orientation imaging—the emergence of a new microscopy. Metall Trans a-Phys Metall Mater Sci 24:819–831

Beladi H, Rohrer GS (2013) The relative grain boundary area and energy distributions in a ferritic steel determined from three-dimensional electron backscatter diffraction maps. Acta Mater 61:1404–1412. doi:10.1016/j.actamat.2012.11.017

Dillon SJ, Rohrer GS (2009) Characterization of the grain-boundary character and energy distributions of yttria using automated serial sectioning and ebsd in the fib. J Am Ceram Soc 92:1580–1585. doi:10.1111/j.1551-2916.2009.03064.x

Rohrer GS, Li J, Lee S, Rollett AD, Groeber M, Uchic MD (2010) Deriving grain boundary character distributions and relative grain boundary energies from three-dimensional ebsd data. Mater Sci Technol 26:661–669. doi:10.1179/026708309X12468927349370

Saylor DM, Morawiec A, Rohrer GS (2002) Distribution and energies of grain boundaries in magnesia as a function of five degrees of freedom. J Am Ceram Soc 85:3081–3083

Rohrer GS, Saylor DM, El Dasher B, Adams BL, Rollett AD, Wynblatt P (2004) The distribution of internal interfaces in polycrystals. Zeitschrift Fur Metallkunde 95:197–214

Beladi H, Rohrer GS (2013) The distribution of grain boundary planes in interstitial free steel. Metall Mater Trans A Phys Metall Mater Sci 44A:115–124. doi:10.1007/s11661-012-1393-0

Ratanaphan S, Yoon Y, Rohrer GS (2014) The five parameter grain boundary character distribution of polycrystalline silicon. J Mater Sci 49:4938–4945. doi:10.1007/s10853-014-8195-2

Saylor DM, El Dasher B, Sano T, Rohrer GS (2004) Distribution of grain boundaries in srtio3 as a function of five macroscopic parameters. J Am Ceram Soc 87:670–676

Saylor DM, El Dasher BS, Rollett AD, Rohrer GS (2004) Distribution of grain boundaries in aluminum as a function of five macroscopic parameters. Acta Mater 52:3649–3655. doi:10.1016/j.actamat.2004.04.018

Rohrer GS (2011) Grain boundary energy anisotropy: a review. J Mater Sci 46:5881–5895. doi:10.1007/s10853-011-5677-3

Rohrer GS (2011) Measuring and interpreting the structure of grain-boundary networks. J Am Ceram Soc 94:633–646. doi:10.1111/j.1551-2916.2011.04384.x

Rauch EF, Barmak K, Ganesh K et al (2011) Tem automated orientation and phase mapping for thin film applications. Microsc Microanal 17:1086–1087

Rauch EF, Dupuy L (2005) Rapid spot diffraction patterns identification through template matching. Arch Metall Mater 50:87–99

Rauch EF, Portillo J, Nicolopoulos S, Bultreys D, Rouvimov S, Moeck P (2010) Automated nanocrystal orientation and phase mapping in the transmission electron microscope on the basis of precession electron diffraction. Zeitschrift Fur Kristallographie 225:103–109. doi:10.1524/zkri.2010.1205

Rauch EF, Veron M (2005) Coupled microstructural observations and local texture measurements with an automated crystallographic orientation mapping tool attached to a tem. Materialwiss Werkstofftech 36:552–556. doi:10.1002/mawe.200500923

Carpenter JS, Liu X, Darbal A et al (2012) A comparison of texture results obtained using precession electron diffraction and neutron diffraction methods at diminishing length scales in ordered bimetallic nanolamellar composites. Scripta Mater 67:336–339. doi:10.1016/j.scriptamat.2012.05.018

Darbal A, Ganesh K, Barmak K et al (2011) Grain boundary characterization of nanocrystalline cu from the stereological analysis of transmission electron microscope orientation maps. Microsc Microanal 17:1416–1417

Darbal AD, Ganesh KJ, Liu X et al (2013) Grain boundary character distribution of nanocrystalline cu thin films using stereological analysis of transmission electron microscope orientation maps. Microsc Microanal 19:111–119. doi:10.1017/s1431927612014055

Liu X, Choi D, Beladi H, Nuhfer NT, Rohrer GS, Barmak K (2013) The five-parameter grain boundary character distribution of nanocrystalline tungsten. Scripta Mater 69:413–416. doi:10.1016/j.scriptamat.2013.05.046

Liu X, Nuhfer NT, Rollett AD et al (2014) Interfacial orientation and misorientation relationships in nanolamellar Cu/Nb composites using transmission-electron-microscope-based orientation and phase mapping. Acta Mater 64:333–344. doi:10.1016/j.actamat.2013.10.046

Liu X, Nuhfer NT, Warren AP, Coffey KR, Rohrer GS, Barmak K (2015) Grain size dependence of the twin length fraction in nanocrystalline cu thin films via transmission electron microscopy based orientation mapping. J Mater Res 30:528–537. doi:10.1557/jmr.2014.393

Liu X, Warren AP, Nuhfer NT, Rollett AD, Coffey KR, Barmak K (2014) Comparison of crystal orientation mapping-based and image-based measurement of grain size and grain size distribution in a thin aluminum film. Acta Mater 79:138–145. doi:10.1016/j.actamat.2014.07.014

Randle V, Rohrer GS, Miller HM, Coleman M, Owen GT (2008) Five-parameter grain boundary distribution of commercially grain boundary engineered nickel and copper. Acta Mater 56:2363–2373. doi:10.1016/j.actamat.2008.01.039

Ratanaphan S, Raabe D, Sarochawikasit R, Olmsted DL, Rohrer GS, Tu KN (2017) Grain boundary character distribution in electroplated nanotwinned copper. J Mater Sci 52:4070–4085. doi:10.1007/s10853-016-0670-5

Barmak K, Eggeling E, Kinderlehrer D et al (2013) Grain growth and the puzzle of its stagnation in thin films: the curious tale of a tail and an ear. Prog Mater Sci 58:987–1055. doi:10.1016/j.pmatsci.2013.03.004

Yao B, Petrova RV, Vanfleet RR, Coffey KR (2006) A modified back-etch method for preparation of plan-view high-resolution transmission electron microscopy samples. J Electron Microsc 55:209–214. doi:10.1093/jmicro/dfl027

Wright SI, Larsen RJ (2002) Extracting twins from orientation imaging microscopy scan data. J Microsc Oxford 205:245–252. doi:10.1046/j.1365-2818.2002.00992.x

Bojarski SA, Stuer M, Zhao Z, Bowen P, Rohrer GS (2014) Influence of Y and La additions on grain growth and the grain-boundary character distribution of alumina. J Am Ceram Soc 97:622–630. doi:10.1111/jace.12669

Holm EA, Rohrer GS, Foiles SM, Rollett AD, Miller HM, Olmsted DL (2011) Validating computed grain boundary energies in fcc metals using the grain boundary character distribution. Acta Mater 59:5250–5256. doi:10.1016/j.actamat.2011.05.001

Rohrer GS (2015) http://mimp.materials.cmu.edu/~gr20/Grain_Boundary_Data_Archive/

Saylor DM, El-Dasher BS, Adams BL, Rohrer GS (2004) Measuring the five-parameter grain-boundary distribution from observations of planar sections. Metall Mater Trans A Phys Metall Mater Sci 35A:1981–1989

Dingley D (2004) Progressive steps in the development of electron backscatter diffraction and orientation imaging microscopy. J Microsc Oxford 213:214–224. doi:10.1111/j.0022-2720.2004.01321.x

Humphreys FJ (2001) Review—grain and subgrain characterisation by electron backscatter diffraction. J Mater Sci 36:3833–3854. doi:10.1023/a:1017973432592

Barmak K Coffey KR (eds) (2014) Metallic films for electronic, optical and magnetic applications Woodhead Publishing, Cambridge

Beladi H, Nuhfer NT, Rohrer GS (2014) The five-parameter grain boundary character and energy distributions of a fully austenitic high-manganese steel using three dimensional data. Acta Mater 70:281–289. doi:10.1016/j.actamat.2014.02.038

Dillon SJ, Rohrer GS (2009) Mechanism for the development of anisotropic grain boundary character distributions during normal grain growth. Acta Mater 57:1–7. doi:10.1016/j.actamat.2008.08.062

Gruber J, George DC, Kuprat AP, Rohrer GS, Rollett AD (2005) Effect of anisotropic grain boundary properties on grain boundary plane distributions during grain growth. Scripta Mater 53:351–355. doi:10.1016/j.scriptamat.2005.04.004

Gruber J, Miller HM, Hoffmann TD, Rohrer GS, Rollett AD (2009) Misorientation texture development during grain growth. Part I: simulation and experiment. Acta Mater 57:6102–6112. doi:10.1016/j.actamat.2009.08.036

Denteneer PJH, Soler JM (1991) Defect energetics in aluminum. J Phys Condens Matter 3:8777–8792. doi:10.1088/0953-8984/3/45/003

Hammer B, Jacobsen KW, Milman V, Payne MC (1992) Stacking-fault energies in aluminum. Journal of Physics-Condensed Matter 4:10453–10460. doi:10.1088/0953-8984/4/50/033

Wright AF, Daw MS, Fong CY (1992) Theoretical investigation of (111)-stacking faults in aluminum. Philos Mag A Phys Condens Matter Struct Defects Mech Prop 66:387–404

Xu JH, Lin W, Freeman AJ (1991) Twin-boundary and stacking-fault energies in Al and Pd. Phys Rev B 43:2018–2024. doi:10.1103/PhysRevB.43.2018

Gallaghe PC (1970) Influence of alloying, temperature, and related effects on stacking fault energy. Metall Trans 1:2429–2430

Meyers MA, Murr LE (1978) Model for formation of annealing twins in fcc metals and alloys. Acta Metall 26:951–962. doi:10.1016/0001-6160(78)90046-9

Oh DJ, Johnson RA (1988) Simple embedded atom method model for fcc and hcp metals. J Mater Res 3:471–478. doi:10.1557/jmr.1988.0471

Chen MW, Ma E, Hemker KJ, Sheng HW, Wang YM, Cheng XM (2003) Deformation twinning in nanocrystalline aluminum. Science 300:1275–1277. doi:10.1126/science.1083727

Narayan J, Zhu YT (2008) Self-thickening, cross-slip deformation twinning model. Appl Phys Lett. doi:10.1063/1.2911735

Zhu YT, Liao XZ, Wu XL (2008) Deformation twinning in bulk nanocrystalline metals: experimental observations. JOM 60:60–64. doi:10.1007/s11837-008-0120-1

Legros M, Hemker KJ, Gouldstone A, Suresh S, Keller-Flaig RM, Arzt E (2002) Microstructural evolution in passivated al films on si substrates during thermal cycling. Acta Mater 50:3435–3452. doi:10.1016/s1359-6454(02)00157-x

Miyazawa K, Iwasaki Y, Ito K, Ishida Y (1996) Combination rule of sigma values at triple junctions in cubic polycrystals. Acta Crystallogr Sect A 52:787–796. doi:10.1107/s0108767396005934

Thompson CV (2000) Structure evolution during processing of polycrystalline films. Annu Rev Mater Sci 30:159–190. doi:10.1146/annurev.matsci.30.1.159

Olmsted DL, Foiles SM, Holm EA (2009) Survey of computed grain boundary properties in face-centered cubic metals: I. Grain boundary energy. Acta Mater 57:3694–3703. doi:10.1016/j.actamat.2009.04.007

Nix WD (2014) Metallic thin films: stresses and mechanical properties. In: Barmak K, Coffey KR (eds) Metallic films for electronic, optical and magnetic applications. Woodhead Publishing, Cambridge

Acknowledgements

Financial support of the SRC, Task 1292.008, 2121.001, 2323.001 and of the MRSEC programs of the NSF under DMR-0520425 and DMR-1420634 is gratefully acknowledged. G.S.R. acknowledges support from the National Science Foundation under Grant DMR 1628994 and use of the Materials Characterization Facility at Carnegie Mellon University supported by Grant MCF-677785.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

No conflicts of interest exist for any of the authors.

Rights and permissions

About this article

Cite this article

Rohrer, G.S., Liu, X., Liu, J. et al. The grain boundary character distribution of highly twinned nanocrystalline thin film aluminum compared to bulk microcrystalline aluminum. J Mater Sci 52, 9819–9833 (2017). https://doi.org/10.1007/s10853-017-1112-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1112-8