Abstract

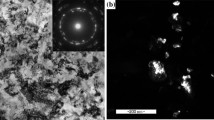

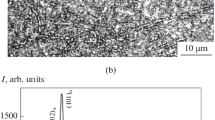

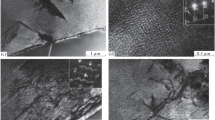

The effect of volume fraction of the β-phase on the mechanical and superplastic properties of ultrafine-grained titanium alloys with grain size d of ~0.2 µm was investigated by transmission and scanning electron microscopy, X-ray diffraction analysis, and tensile test experiments. The ultrafine-grained structure of the materials was formed by the multi-directional pressing technique. The structure in question is shown to improve the mechanical properties by 30–50 % and to lower down to 823 K, the temperature at which superplastic flow starts as compared to coarse-grained analogs, no matter what the phase composition and concentration of the alloying elements used. The reduced temperature is attributable to the activation of diffusion-controlled grain boundary sliding in the case of nonequilibrium interfaces of materials produced by severe plastic deformation. The fraction of the β-phase and its precipitation pattern are found to have significant influence on the temperature range in which superplastic flow occurs and on the maximum elongation to failure. A near-β Ti-5Al-5Mo-5V-1Cr-1Fe alloy with a large fraction of the β-phase (>34 %) under superplastic conditions exhibits record-breaking strains (>1300 %) that do not cause fracture of the material and extremely low flow stresses. This is associated with the activation of the grain boundary sliding due to an increase in the diffusivity along the phase boundaries in a case of microduplex structure.

Similar content being viewed by others

References

Watanabe T (2011) Grain boundary engineering: historical perspectives and future prospects. J Mater Sci 46:4095–4115. doi:10.1007/s10853-011-5393-z

Kaibyshev OA, Valiev RZ (1987) Grain boundaries and metal properties. Metallurgy, Moscow (In Russian)

Kolobov YuR, Valiev RZ, Grabovetskaya GP, Zhilyaev AP, Dudarev EF, Ivanov KV, Ivanov MB, Kashin OA, Naydenkin EV (2007) Grain boundary diffusion and properties of nanostructured materials. Cambridge International Science Publishing, Cambridge

Panin VE, Egorushkin VE (2015) Basic physical mesomechanics of plastic deformation and fracture of solids as hierarchically organized nonlinear systems. Phys Mesomech 18:377–390

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51:427–556

Valiev RZ, Zhilyaev AP, Langdon TG (2013) Bulk nanostructured materials: fundamentals and applications. Wiley, New Jersey

Valiev RZ (2002) Materials science: nanomaterial advantage. Nature 419:887–889

Zhilyaev AP, Pshenichnyuk AI (2011) Superplasticity and grain boundaries in ultrafine-grained materials. Woodhead Publishing Ltd, Cambridge

Cantor B, Grant P, Assender H (eds) (2001) Aerospace Materials. IOP Publishing, Bristol

Naydenkin EV, Ratochka IV, Grabovetskaya GP (2011) The aspects of practical application of ultrafine-grained titanium alloys produced by severe plastic deformation. Mater Sci Forum 667–669:1183–1188

Edington JW, Melton KN, Cutler CP (1976) Superplasticity. Prog Mater Sci 21:61–170

Naydenkin EV, Ratochka IV (2008) The features of deformation behavior of ultra-fine grained titanium and aluminum alloys under conditions of high strain rate superplasticity. Mater Sci Forum 584–586:159–163

Matsumoto H, Yoshida K, Lee S-H, Ono Y, Chiba A (2013) Ti–6Al–4V alloy with an ultrafine-grained microstructure exhibiting low-temperature–high-strain-rate superplasticity. Mater Let 98:209–212

Seshacharyulu T, Medeiros SC, Frazier WG, Prasad YVRK (2000) Hot working of commercial Ti–6Al–4V with an equiaxed α–β microstructure: materials modeling considerations. Mater Sci Eng A 284:184–194

Ashida M, Chen P, Doi H, Tsutsumi Y, Hanawa T, Horita Z (2015) Superplasticity in the Ti-6Al-7Nb alloy processed by high-pressure torsion. Mater Sci Eng A 640:449–453

Dudarev EF, Pochivalova GP, Kolobov YuR, Naydenkin EV, Kashin OA (2009) Diffusion -controlled true grain-boundary sliding in nanostructured metals and alloys. Mater Sci Eng A 503:58–61

Kaibyshev OA (1992) Superplasticity of alloys, intermetallides and ceramics. Springer, Berlin

Langdon TG (1994) A unified approach to grain boundary sliding in creep and superplasticity. Acta Met Mater 42:2437–2443

Kaur I, Mishin Y, Gust W (1995) Fundamentals of grain and interphase boundary diffusion. Wiley, Chichester

Alabort E, Kontis P, Barba D, Dragnevski K, Reed RC (2016) On the mechanisms of superplasticity in Ti-6Al-4V. Acta Mat 105:449–463

Valiev R, Langdon T (1993) An investigation of the role of intragranular dislocation strain in the superplastic Pb-62%Sn eutectic alloy. Acta Met Mater 41:949–954

Martienssen W, Effenberg G, Ilyenko S (eds) (2008) Ternary alloy systems. Phase diagrams, crystallographic and thermodynamic data. Springer, Berlin

Naydenkin EV, Ivanov KV (2014) The changes in phase composition of the subsurface layer of an ultrafine-grained Al-Mg-Li alloy during its deformation under superplasticity conditions. Russ Phys J 56:1018–1024

Acknowledgements

The work was performed within a state assignment (Project No. 23.2.2) and supported in part by a program of the Presidium of the Russian Academy of Sciences (Project No. IIП/III.23-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naydenkin, E.V., Ratochka, I.V., Mishin, I.P. et al. The effect of interfaces on mechanical and superplastic properties of titanium alloys. J Mater Sci 52, 4164–4171 (2017). https://doi.org/10.1007/s10853-016-0508-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0508-1