Abstract

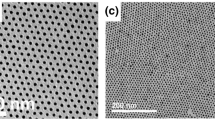

In the analysis of complex, hierarchical structural meta-materials, it is critical to understand the mechanical behavior at each level of hierarchy in order to understand the bulk material response. We report the fabrication and mechanical deformation of hierarchical hollow tube lattice structures with features ranging from 10 nm to 100 μm, hereby referred to as nanolattices. Titanium nitride (TiN) nanolattices were fabricated using a combination of two-photon lithography, direct laser writing, and atomic layer deposition. The structure was composed of a series of tessellated regular octahedra attached at their vertices. In situ uniaxial compression experiments performed in combination with finite element analysis on individual unit cells revealed that the TiN was able to withstand tensile stresses of 1.75 GPa under monotonic loading and of up to 1.7 GPa under cyclic loading without failure. During the compression of the unit cell, the beams bifurcated via lateral-torsional buckling, which gave rise to a hyperelastic behavior in the load–displacement data. During the compression of the full nanolattice, the structure collapsed catastrophically at a high strength and modulus that agreed well with classical cellular solid scaling laws given the low relative density of 1.36 %. We discuss the compressive behavior and mechanical analysis of the unit cell of these hollow TiN nanolattices in the context of finite element analysis in combination with classical buckling laws, and the behavior of the full structure in the context of classical scaling laws of cellular solids coupled with enhanced nanoscale material properties.

Similar content being viewed by others

References

Hutchens SB, Needleman A, Greer JR (2012) A microstructurally motivated description of the deformation of vertically aligned carbon nanotube structures. Appl Phys Lett 100:121910

Pathak S, Lim EJ, Abadi PPSS, Graham S, Cola BA, Greer JR (2012) Higher recovery and better energy dissipation at faster strain rates in carbon nanotube bundles: an in situ study. ACS Nano 6:2189–2197

Cao A, Dickrell PL, Sawyer WG, Ghasemi-Nejhad MN, Ajayan PM (2005) Super-compressible foamlike carbon nanotube films. Science 310:1307–1310

Schaedler TA, Jacobsen AJ, Torrents A, Sorensen AE, Lian J, Greer JR, Carter WB (2011) Ultralight metallic microlattices. Science 334:962–965

Torrents A, Schaedler TA, Jacobsen AJ, Carter WB, Valdevit L (2012) Characterization of nickel-based microlattice materials with structural hierarchy from the nanometer to the millimeter scale. Acta Mater 60:3511–3523

Sandhage KH, Dickerson MB, Huseman PM, Caranna MA, Clifton JD, Bull TA, Heibel TJ, Overton WR, Schoenwaelder ME (2002) Novel, bioclastic route to self-assembled, 3D, chemically tailored meso/nanostructures: shape-preserving reactive conversion of biosilica (diatom) microshells. Adv Mater 14:429–433

Gibson LJ, Ashby MF (1999) Cellular solids: structure and properties, 2nd edn. Cambridge University Press, Cambridge

Fleck NA, Deshpande VS, Ashby MF (2010) Micro-architectured materials: past, present and future. Proc R Soc A 466:2495–2516

Pellegrino S, Calladine CR (1986) Matrix analysis of statically and kinematically indeterminate frameworks. Int J Solids Struct 22:409–428

Hutchinson RG, Fleck NA (2006) The structural performance of the periodic truss. J Mech Phys Solids 54:756–782

Deshpande VS, Fleck NA, Ashby MF (2001) Effective properties of the octet-truss lattice material. J Mech Phys Solids 49:1747–1769

Tekog˜lu C, Gibson LJ, Pardoen T, Onck PR (2011) Size effects in foams: experiments and modeling. Prog Mater Sci 56:109–138

Hamm CE, Merkel R, Springer O, Jurkojc P, Maier C, Prechtel K, Smetacek V (2003) Architecture and material properties of diatom shells provide effective mechanical protection. Nature 421:841–843

Luz GM, Mano JF (2009) Biomimetic design of materials and biomaterials inspired by the structure of nacre. Philos Trans R Soc A 367:1587–1605

Wang C, Huang Y, Zan Q, Guo H, Cai S (2000) Biomimetic structure design: a possible approach to change the brittleness of ceramics in nature. Mater Sci Eng C 11:9–12

Tetrault N, Freymann G, Deubel M, Hermatschweiler M, Perez-Willard F, John S, Wegener M, Ozin GA (2006) New route to three-dimensional photonic bandgap materials: silicon double inversion of polymer templates. Adv Mater 18:457–460

Jang D, Meza L, Greer F, Greer JR (2013) Fabrication and deformation of three-dimensional hollow ceramic nanostructures. Nat Mater 12:893–898

Kim JY, Greer JR (2009) Tensile and compressive behavior of gold and molybdenum single crystals at the nanoscale. Acta Mater 57:5245–5253

Timoshenko SP (1934) Theory of elasticity, 1st edn. McGraw-Hill Book Company, New York

Timoshenko SP, Gere JM (1961) Theory of elastic stability, 2nd edn. McGraw-Hill Book Company, New York

Akimov YK (2003) Field of application of aerogels (review). Instrum Exp Tech 46:287–299

Jones RM (2006) Buckling of bars plates and shells, 1st edn. Bull Ridge Publishing, Blacksburg

Kumar S, Wolfe DE, Haque MA (2011) Dislocation shielding and flaw tolerance in titanium nitride. Int J Plast 27:729–747

Shackelford JF, Alexander W (2000) Materials science and engineering handbook, 3rd edn. CRC Press Inc., Boca Raton

Gu XW, Wu Z, Zhang YW, Srolovitz DJ, Greer JR (2013) Flaw-driven failure in nanostructures. Nanoletters 13:5703–5709

Gao H, Ji B, Jager IL, Arzt E, Fratzl P (2003) Materials become insensitive to flaws at nanoscale: lessons from nature. Proc Natl Acad Sci 100:5597–5600

Meyers MA, Chawla KK (1998) Mechanical behavior of materials, 1st edn. Prentice-Hall Inc., Upper Saddle River

Andrievski R (1997) Physical-mechanical properties of nanostructured titanium nitride. Nanostruct Mater 9:607–610

Kim HS, Bush MB (1999) The effects of grain size and porosity on the elastic modulus of nanocrystalline materials. Nanostruct Mater 11:361–367

George SM (2010) Atomic layer deposition: an overview. Chem Rev 110:111–131

Sanders PG, Eastman JA, Weertman JR (1997) Elastic and tensile behavior of nanocrystalline copper and palladium. Acta Mater 45:4019–4025

Law K, Gardner L (2012) Lateral instability of elliptical hollow section beams. Eng Struct 37:152–166

Li C, Ru CQ, Mioduchowski A (2006) Torsion of the central pair microtubules in eukaryotic flagella due to bending-driven lateral buckling. Biochem Biophys Res Commun 351:159–164

McCann RC and Suryanarayana PVR (1994) Experimental study of curvature and frictional effects on buckling. In: Offshore technology conference

Suryanarayana PVR, McCann RC (1995) An experimental study of buckling and post-buckling of laterally constrained rods. J Energy Res Technol 117:115–124

Acknowledgements

The authors gratefully acknowledge the financial support from the Dow-Resnick Innovation Fund at Caltech, the Office of Naval Research (Grant N000140910883) and the Army Research Office through the Institute for Collaborative Biotechnologies (ICB) at Caltech (ARO Award number UCSB.ICB4b). Part of this work was carried out at the Jet Propulsion Laboratory under a contract with NASA. The authors acknowledge critical support and infrastructure provided by the Kavli Nanoscience Institute at Caltech. The authors thank Dongchan Jang for his help with nanomechanical experiments. The authors also thank Frank Greer for his help in the ALD deposition of the TiN films.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meza, L.R., Greer, J.R. Mechanical characterization of hollow ceramic nanolattices. J Mater Sci 49, 2496–2508 (2014). https://doi.org/10.1007/s10853-013-7945-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7945-x