Abstract

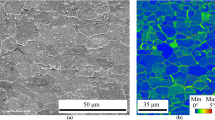

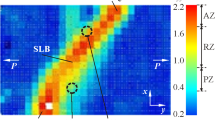

Interstitial free sheet steels show transient work hardening behavior, i.e., the Bauschinger effect and cross hardening, after changes in the loading path. This behavior affects sheet forming processes and the properties of the final part. The transient work hardening behavior is attributed to changes in the dislocation structure. In this work, the morphology of the dislocation microstructure is investigated for uniaxial and plane strain tension, monotonic and forward to reverse shear, and plane strain tension to shear. Characteristic features such as the thickness of cell walls and the shape of cells are used to distinguish microstructural patterns corresponding to different loading paths. The influence of the crystallographic texture on the dislocation structure is analyzed. Digital image processing is used to create a “library” of schematic representations of the dislocation microstructure. The dislocation microstructures corresponding to uniaxial tension, plane strain tension, monotonic shear, forward to reverse shear, and plane strain tension to shear can be distinguished from each other based on the thickness of cell walls and the shape of cells. A statistical analysis of the wall thickness distribution shows that the wall thickness decreases with increasing deformation and that there are differences between simple shear and uniaxial tension. A change in loading path leads to changes in the dislocation structure. The knowledge of the specific features of the dislocation structure corresponding to a loading path may be used for two purposes: (i) the analysis of the homogeneity of deformation in a test sample and (ii) the analysis of a formed part.

Similar content being viewed by others

References

Nesterova EV, Bacroix B, Teodosiu C (2001) Mater Sci Eng A 309–310:495

Nesterova EV, Bacroix B, Teodosiu C (2001) Metall Mater Trans A 32A:2527

Fernandes JV, Schmitt JH (1983) Philos Mag 48:841

Pantleon W, Stoyan D (2000) Acta Mater 48:3005

Rauch EF, Schmitt JH (1989) Mater Sci Eng A 113:441

Lins JFC, Sandim HRZ, Kestenbach HJ (2007) J Mater Sci 42:6572. doi:10.1007/ s10853-007-1515-z

Wilson DV, Bate PS (1994) Acta Metall Mater 42:1099

Vincze G, Rauch EF, Gracio JJ, Barlat F, Lopes AB (2005) Acta Mater 53:1005

Hasegawa T, Yakou T, Karashima S (1975) Mater Sci Eng 20:267

Bouvier S, Alves J, Oliveira M, Menezes L (2005) Comput Mater Sci 32:301

Figueiredo R, Corrêa E, Monteiro W, Aguilar M, Cetlin P (2010) J Mater Sci 45:804. doi:10.1007/s10853-009-4003-9

Ding X, He G, Chen C (2010) J Mater Sci 45:4046. doi:10.1007/s10853-010-4487-3

Landau P, Shneck R, Makov G, Venkert A (2007) J Mater Sci 42:9775. doi:10.1007/s10853-007-1999-6

Thuillier S, Rauch EF (1994) Acta Metall Mater 42:1973

Teodosiu C, Hu Z (1998) Microstructure in the continuum modelling of plastic anisotropy. Proc 19th Risø Inter Symp Mater Sci: Model Struct Mech Mater Mic Prod, Risø Nat Lab, Roskilde, Denmark, p 149

Noman M, Clausmeyer T, Barthel C, Svendsen B, Huétink J, van Riel M (2010) Mater Sci Eng A 527:2515

Teodosiu C, Hu Z (1995) In: Shen SF, Dawson PR (eds) Sim mater process: theory, methods and applications. Balkema, Rotterdam, p 173

Wang J, Levkovitch V, Reusch F, Svendsen B, Huétink J, van Riel M (2008) Int J Plast 24:1039

Peeters B, Kalidindi SR, Teodosiu C, van Houtte P, Aernoudt E (2002) J Mech Phys Solid 50:783

Holmedal B, van Houtte P, An Y (2008) Int J Plast 24:1360

Beyerlein I, Alexander D, Tomé C (2007) J Mater Sci 42:1733. doi:10.1007/s10853-006-0906-x

Wang J, Levkovitch V, Svendsen B (2006) J Mater Process Techol 177:430

Thuillier S, Manach PY, Menezes LF (2010) J Mater Process Techol 210:226

van Riel M, van den Boogaard AH (2007) Scr Mater 57:381

Cao J, Shi MF, Stoughton TB, Wang CT, Zhang L (2005) Proc NUMISHEET 2005: The Numisheet 2005 Benchmark Study, Part B, Detroit. Am Inst Phys 778:881

DIN EN 10130 (2006) Cold rolled low carbon steel flat products for cold forming Technical delivery conditions. Techn rep DIN

Clausmeyer T, van den Boogaard AH, Noman M, Gershteyn G, Schaper M, Svendsen B, Bargmann S (2011) Int J Mater Form 4:141

van Riel M (2009) Strain path dependency in sheet metal—experiments and models. Dissertation, Universiteit Twente

Kuwabara T (2007) Int J Plast 23:385

Hu Z (1994) Acta Metall Mater 42:3481

Bouvier S, Teodosiu C, Haddadi H, Tabacaru V (2003) J Phys IV France 105:215

Bauschinger J (1881) Zivilingenieur 21:289

Hielscher R, Schaeben H (2008) J Appl Crystallogr 41:1024

Bacroix B, Hu Z (1995) Metall Mater Trans A 26:601

Hughes DA, Hansen N (1991) Mater Sci Technol 7:544

Kuhlmann-Wilsdorf D, Hansen N (1991) Scr Metall Mater 25:1557

Kuhlmann-Wilsdorf D (1989) Mater Sci Eng A 113:1

Juda U, Frank-Rotsch C, Rudolph P (2008) J Mater Sci 19:342. doi:10.1007/s10854-007-9554-4

Kurzydłowski KJ (1995) The quantitative description of the microstructure of materials. CRC Press, London

Rasband WS (2004) ImageJ. National Institutes of Health, Bethesda, http://rsb.info.nih.gov/ij/. Accessed July 12 2012

Gonzalez RC, Woods RE, Eddins SL (2008) Digital image processing using MATLAB®. Gatesmark Publishing, Knoxville

Bailey JE, Hirsch PB (1960) Philos Mag 5:485

Stremel MA, Belyakov BG (1968) Phys Metal Metallogr 25:140

Rybin VV (1986) Severe plastic deformations and fracture of metals. Metallurgiya, Moscow

Li BL, Godfrey A, Meng QC, Liu Q, Hansen N (2004) Acta Mater 52:1069

Keh AS, Spitzig WA, Nakada Y (1971) Philos Mag 23:829

Spitzig WA, Keh AS (1971) Metall Trans 1:2751

Böhm H (1968) Einführung in die Metallkunde. Verlag Bibliographisches Institut AG, Mannheim

Haddadi H, Bouvier S, Banu M, Maier C, Teodosiu C (2006) Int J Plast 22:2226

Pantleon W (1998) Acta Mater 46:451

Hughes DA, Hansen N (2000) Acta Mater 48:2985

Langford G, Cohen M (1975) Metall Mater Trans A 6:901

GodfreyA Hughes DA (2000) Acta Mater 48:1897

Acknowledgements

Financial support for this work provided by the German Science Foundation (DFG) under contract PAK 250 (TP3, TP4, TP5) is greatly acknowledged. The material investigated for this paper was provided and chemically analyzed by ThyssenKrupp Steel Europe AG. The authors thank Dr.-Ing. Malek Homayonifar from the Institute of Mechanics for valuable discussions on texture. The authors also thank the reviewers of a previous version for the instructive and helpful comments which have led to a considerable improvement of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Clausmeyer, T., Gerstein, G., Bargmann, S. et al. Experimental characterization of microstructure development during loading path changes in bcc sheet steels. J Mater Sci 48, 674–689 (2013). https://doi.org/10.1007/s10853-012-6780-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6780-9