Abstract

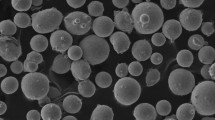

The formation mechanism and coarsening behavior of fan-type structures in a new Ni–Cr–Co-based powder metallurgy superalloy were investigated by means of field scanning electron microscope, transmission electron microscope, electron backscattered diffraction, and differential scanning calorimetry. The results show that the fan-type structures consist of finger-shaped γ′ dendrites and γ matrix between them. They nucleate in the chemical segregation regions on grain boundaries and grow by diffusion. There are three types of solute atoms flow: (a) rapid diffusion along grain boundary; (b) the diffusion from supersaturated γ matrix to fan-type γ′ phases; and (c) short-distance diffusion from the previous formed γ′ phases at high temperature to γ′ phases formed at low temperature within the branches of fan-type structures. These γ′ dendrites are perpendicular to grain boundaries and grow asymmetrically, resulting in grain boundary serration. In addition, the fan-type structures coarsen within the γ′ depletion zone after the standard aging treatment.

Similar content being viewed by others

References

Larson JM, Volin TE, Larson FG (1977) Micro Sci 5:209

Furrer DU (1999) Scripta Mater 40:1215

Furrer DU (2007) Proceeding of the eleventh international symposium on advanced superalloys-production and application CSM:192

Mitchell RJ, Li HY, Huang ZW (2009) J Mate Process Tech 209:1011

Lu XD, Deng Q, Du JH, Qu JL, Zhuang JY, Zhong ZY (2009) J Alloy Compd 477:100

Lu XD, Du JH, Deng Q, Zhong ZY (2009) J Alloy Compd 486:195

Huang SC, Chang KM (1984) J Mater Sci 19:1220. doi:10.1007/BF01120032

Dwarapureddy AK, Balikci E, Ibekwe S, Raman A (2008) J Mater Sci 43:1802. doi:10.1007/s10853-007-2342-y

Lemsky J (2004) Assessment of NASA dual microstructure heat treatment method for multiple forging batch heat treatments. NASA-CR-212950, NASA. Glenn Research Center, Cleveland

Gabb TP, Gayda J (2005) Forging of advanced disk alloy LSHR. NASA-TM-213649, NASA. Glenn Research Center, Cleveland

Wu K, Liu GQ, Hu BF, Wu H, Zhang YW, Tao Y, Liu JT (2009) J Univ Sci Tech B 31:719 (in Chinese)

Morinaga M, Yukawa N, Adachi H (1984) J Phys Soc Jpn 53:653

Yukama N, Morinaga M, Murata Y, Ezaki H, Inouet S (1988) Superalloys, vol 225. TMS, Warrendale, pp 765–774

TTNI8 (2009) Thermotech Ni-based superalloys database Version 8.0”, ThermoTech, www.thermocalc.com

ASTM Standard E112, 2004e2 (2004) Standard test methods for determining average grain size. ASTM International, West Conshohocken. doi:10.1520/E0112-96R04E02. www.astm.org

Staron P, Kampmann R (2000) Acta Mater 48:701

Staron P, Kampmann R (2000) Acta Mater 48:713

Assadi H, Schroers J (2002) Acta Mater 50:89

Ricks RA, Porter AJ, Ecob RC (1983) Acta Metall 31:43

Henry MF, Yoo YS, Yoon DY, Choi J (1993) Metall Trans A 24:1733

Zhang JH, Yao XD, Zhang ZY, Li YA, Guan HR, Hu ZQ (1994) Acta Metall Sin 30:453 (in Chinese)

Yoo YS (2005) Scripta Mater 53:81

Acknowledgement

This study was financially supported by National Pre-research Funds and High Technology Research and Development Program of China (No. 2007AA03A223).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, K., Liu, G.Q., Hu, B.F. et al. Formation mechanism and coarsening behavior of fan-type structures in a new Ni–Cr–Co-based powder metallurgy superalloy. J Mater Sci 47, 4680–4688 (2012). https://doi.org/10.1007/s10853-012-6336-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6336-z