Abstract

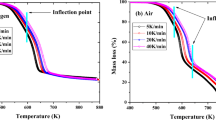

Cellulose, hemicellulose and lignin are generally recognized as the main components of sawdust. In this paper, the spontaneous combustion mechanism of sawdust was studied from the aspect of these components. The thermogravimetry analysis and biochemical component analysis showed that the lignin decomposed evidently at the induction period of thermal decomposition of sawdust, and the lignin contents of sawdust also presented positive correlation with their spontaneous combustion risk. Scanning electron microscope, fourier transform infrared spectroscopy and X-ray photoemission spectra were implemented further. The results showed that: the cellulose remained stable at the induction period; for hemicellulose, the oxidation reaction took place, but it was very weak. However, for lignin, the dehydration reaction (loss hydroxyl group of alcohols) took place evidently so that the lignin exhibited an apparent porous structure. Therefore, the dehydration reaction of lignin might greatly affect the spontaneous combustion of sawdust.

Similar content being viewed by others

References

Antal MJ, Gronli M (2003) The art, science, and technology of charcoal production. Ind Eng Chem Res 42:1619–1640

ASTM (2013a) D1102-84 standard test method for ash in wood. United States

ASTM (2013b) E871-82 standard test method for moisture analysis of particulate wood fuels. United States

ASTM (2013c) E872-82 standard test method for volatile matter in the analysis of particulate wood fuels. United States

Bobleter O (1994) Hydrothermal degradation of polymers derived from plants. Prog Polym Sci 19:797–841

Cara C, Ruiz E, Ballesteros M, Manzanares P, Negro MJ, Castro E (2008) Production of fuel ethanol from steam-explosion pretreated olive tree pruning. Fuel 87:692–700

Carrier M, Loppinet-Serani A, Denux D, Lasnier JM, Ham-Pichavant F, Cansell F, Aymonier C (2011) Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenerg 35:298–307

Cheng K, Winter WT, Stipanovic AJ (2012) A modulated-TGA approach to the kinetics of lignocellulosic biomass pyrolysis/combustion. Polym Degrad Stab 97:1606–1615

Couhert C, Commandre JM, Salvador S (2009) Is it possible to predict gas yields of any biomass after rapid pyrolysis at high temperature from its composition in cellulose, hemicellulose and lignin? Fuel 88:408–417

Huang D-L, Zeng G-M, Feng C-L, Hu S, Lai C, Zhao M-H, Su F-F, Tang L, Liu H-L (2010) Changes of microbial population structure related to lignin degradation during lignocellulosic waste composting. Biores Technol 101:4062–4067

Li S, Xu S, Liu S, Yang C, Lu Q (2004) Fast pyrolysis of biomass in free-fall reactor for hydrogen-rich gas. Fuel Process Technol 85:1201–1211

Lopez-Gonzalez D, Fernandez-Lopez M, Valverde JL, Sanchez-Silva L (2013) Thermogravimetric-mass spectrometric analysis on combustion of lignocellulosic biomass. Biores Technol 143:562–574

Luo QB, Liang D, Shen H (2016) Evaluation of self-heating and spontaneous combustion risk of biomass and fishmeal with thermal analysis (DSC-TG) and self-heating substances test experiments. Thermochim Acta 635:1–7

Mishra RK, Mohanty K (2018) Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Biores Technol 251:63–74

Mishra RK, Mohanty K (2019) Thermal and catalytic pyrolysis of pine sawdust (Pinus ponderosa) and Gulmohar seed (Delonix regia) towards production of fuel and chemicals. Mater Sci Energy Technol 2:139–149

Pavia DL, Lampman GM, Kriz GS, Vyvyan JA (2014) Introduction to spectroscopy, 5th edn. Cengage Learning, Connecticut

Rao RT, Sharma A (1998) Pyrolysis rates of biomass materials. Energy 23:973–978

Smith M, Scudiero L, Espinal J, McEwen J-S, Garcia-Perez M (2016) Improving the deconvolution and interpretation of XPS spectra from chars by ab initio calculations. Carbon 110:155–171

Smith MW, Helms G, McEwen J-S, Garcia-Perez M (2017a) Effect of pyrolysis temperature on aromatic cluster size of cellulose char by quantitative multi cross-polarization C-13 NMR with long range dipolar dephasing. Carbon 116:210–222

Smith MW, Pecha B, Helms G, Scudiero L, Garcia-Perez M (2017b) Chemical and morphological evaluation of chars produced from primary biomass constituents: cellulose, xylan, and lignin. Biomass Bioenerg 104:17–35

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597

Viel M, Collet F, Lanos C (2018) Chemical and multi-physical characterization of agro-resources’ by-product as a possible raw building material. Ind Crops Prod 120:214–237

Xu WB, He ZL, Luo QB, Shen H, Liang D, Ren T (2018) The inflence of soluble components on spontaneous combustion risk of sawdust samples. Thermochim Acta 670:219–225

Yang HP, Yan R, Chen HP, Zheng CG, Lee DH, Liang DT (2006) In-depth investigation of biomass pyrolysis based on three major components: hemicellulose, cellulose and lignin. Energy Fuels 20:388–393

Zhu X, Liu Y, Zhou C, Luo G, Zhang S, Chen J (2014) A novel porous carbon derived from hydrothermal carbon for efficient adsorption of tetracycline. Carbon 77:627–636

Acknowledgments

This work was supported by Guangdong Provincial Scientific and Technological Project (No. 2014B030301034).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, Q., He, Z., Xu, W. et al. The spontaneous combustion mechanism of sawdust from the aspect of biochemical components. Cellulose 26, 9045–9055 (2019). https://doi.org/10.1007/s10570-019-02697-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02697-2