Abstract

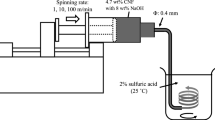

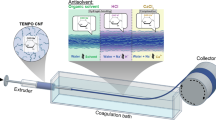

Utilization of cellulose nanofibrils (CNF) for filament production is a comparatively new approach, which can broaden nanocellulose applications by providing continuous long filaments suitable for composite and textile applications. Methods are proposed for the spinning of filaments from cellulose nanofibril suspensions, which are mainly categorized into two groups, i.e. dry-spinning and wet-spinning. For the dry-spinning method, the substrate on which the filament is spun will have a significant influence on the properties of the filament because the as-spun CNF will initially contact it. In this work, the influence of different collection substrates on the properties of CNF filament was studied. Filaments with an average diameter of 0.1 mm were spun on different collection substrates including Teflon tape, Teflon film and glass. The influence of adding oil, as a friction modifier, on the surface properties of the substrate and the structure of the resultant filaments was evaluated. Wettability of each substrate in the absence of oil, and the presence of a thin layer and a thick layer of oil was studied. Circularity of the filaments was measured using image analysis of the cross sections and was correlated with the surface properties of the substrates. It was found that while the surface properties of the collection substrate were related to the uniformity and cross section circularity of the filaments, those spun on a thick layer of oil had the best circular shape irrespective of the substrate material. The results of this study can be used to optimize dry-spinning of CNF filaments.

Graphical abstract

Similar content being viewed by others

References

Abitbol T, Rivkin A, Cao Y, Nevo Y, Abraham E, Ben-Shalom T, Lapidot S, Shoseyov O (2016) Nanocellulose, a tiny fiber with huge applications. Curr Opin Biotechnol 39:76–88

Amini E, Tajvidi M, Gardner DJ, Bousfield DW (2017) Utilization of cellulose nanofibrils as a binder for particleboard manufacture. BioRes 12:4093–4110

Clemons C (2016) Nanocellulose in spun continuous fibers: a review and future outlook. J Renew Mater 5:327–339

Diop CIK, Tajvidi M, Bilodeau MA, Bousfield DW, Hunt JF (2017a) Evaluation of the incorporation of lignocellulose nanofibrils as sustainable adhesive replacement in medium density fiberboards. Ind Crops Prod 109:27–36

Diop CIK, Tajvidi M, Bilodeau MA, Bousfield DW, Hunt JF (2017b) Isolation of lignocellulose nanofibrils (LCNF) and application as adhesive replacement in wood composites: example of fiberboard. Cellulose 24:3037–3050

Dufresne A (2012) Nanocellulose: from nature to high performance tailored materials. De Gruyter, p 460

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 16:220–227

Gardner DJ, Oporto GS, Mills R, Samir MASA (2008) Adhesion and surface issues in cellulose and nanocellulose. J Adhes Sci Technol 22:545–567

Gardner DJ, Blumentritt M, Wang L, Yildirim N (2014) Adhesion theories in wood adhesive bonding. Rev Adhes Adhes 2:127–172

Ghasemi S, Tajvidi M, Bousfield DW, Gardner DJ, Gramlich WM (2017) Dry-spun neat cellulose nanofibril filaments: influence of drying temperature and nanofibril structure on filament properties. Polymers 9:1–13

Ghasemi S, Tajvidi M, Bousfield DW, Gardner DJ (2018) Reinforcement of natural fiber yarns by cellulose nanomaterials: a multi-scale study. Ind Crops Prod 111:471–481

Grande R, Trovatti E, Carvalho A, Gandini A (2017) Continuous microfiber drawing by interfacial charge complexation between anionic cellulose nanofibers and cationic chitosan. J Mater Chem A 5:13098–13103

Håkansson KMO, Fall AB, Lundell F, Yu S, Krywka C, Roth SV, Santoro G, Kvick M, Prahl Wittberg L, Wågberg L, Söderberg LD (2014) Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments. Nat Commun 5:4018

Hooshmand S, Aitomäki Y, Norberg N, Mathew AP, Oksman K (2015) Dry-spun single-filament fibers comprising solely cellulose nanofibers from bioresidue. ACS Appl Mater Interfaces 7:13022–13028

Hooshmand S, Aitomäki Y, Berglund L, Mathew AP, Oksman K (2017) Enhanced alignment and mechanical properties through the use of hydroxyethyl cellulose in solvent-free native cellulose spun filaments. Compos Sci Technol 150:79–86

Iwamoto S, Isogai A, Iwata T (2011) Structure and mechanical properties of wet-spun fibers made from natural cellulose nanofibers. Biomacromolecules 12:831–836

Kaelble DH (1920) Dispersion-polar surface tension properties of organic solids. J Adhes 2:66–81

Kafy A, Kim HC, Zhai L, Kim JW, Hai LV, Kang TJ, Kim J (2017) Cellulose long fibers fabricated from cellulose nanofibers and its strong and tough characteristics. Sci Rep 7:1–8

Leng W, Hunt JF, Tajvidi M (2017a) Screw and nail withdrawal strength and water soak properties of wet-formed cellulose nanofibrils bonded particleboard. BioRes 12:7692–7710

Leng W, Hunt JF, Tajvidi M (2017b) Effects of density, cellulose nanofibrils addition ratio, pressing method, and particle size on the bending properties of wet-formed particleboard. BioRes 12:4986–5000

Lundahl MJ, Klar V, Wang L, Ago M, Rojas OJ (2016a) Spinning of cellulose nanofibrils into filaments: a review. Ind Eng Chem Res 2:8–19

Lundahl MJ, Cunha AG, Rojo E, Papageorgiou AC, Rautkari L, Arboleda JC, Rojas OJ (2016b) Strength and water interactions of cellulose I filaments wet-spun from cellulose nanofibril hydrogels. Sci Rep 6:1–14

Mashkour M, Kimura T, Kimura F, Mashkour M, Tajvidi M (2014) One-dimensional core-shell cellulose-akaganeite hybrid nanocrystals: synthesis, characterization, and magnetic field induced self-assembly. RSC Adv 4:52542–52549

Mittal N, Ansari F, Gowda VK, Brouzet C, Chen P, Larsson PT, Roth SV, Lundell F, Wågberg L, Kotov NA, Söderberg LD (2018) Multiscale control of nanocellulose assembly: transferring remarkable nanoscale fibril mechanics to macroscale fibers. ACS Nano. https://doi.org/10.1021/acsnano.8b01084

Mohammadi P, Toivonen MS, Ikkala O, Wagermaier W, Linder MB (2017) Aligning cellulose nanofibril dispersions for tougher fibers. Sci Rep 7:1–10

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Nechyporchuk O, Bordes R, Köhnke T (2017) Wet spinning of flame-retardant cellulosic fibers supported by interfacial complexation of cellulose nanofibrils with silica nanoparticles. ACS Appl Mater Interfaces 9:39069–39077

Oksman K, Aitomäki Y, Mathew AP, Siqueira G, Zhou Q, Butylina S, Tanpichai S, Zhou X, Hooshmand S (2016) Review of the recent developments in cellulose nanocomposite processing. Compos Part-A Appl Sci 83:2–18

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747

Rabel W (1971) Einige Aspekte der Benetzungstheorie und ihre Anwendung auf die Untersuchung und Veränderung der Oberflächeneigenschaften von Polymeren. In Farbe und Lack 77:997–1005

Revol JF, Bradford H, Giasson J, Marchessault RH, Gray DG (1992) Helicoidal self-ordering of cellulose microfibrils in aqueous suspension. Int J Biol Macromol 14:170–172

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH image to image J: 25 years of image analysis. Nat Methods 9:671–675

Shen Y, Orelma H, Sneck A, Kataja K, Salmela J, Qvintus P, Suurnäkki A, Harlin A (2016) High velocity dry spinning of nanofibrillated cellulose (CNF) filaments on an adhesion controlled surface with low friction. Cellulose 23:3393–3398

Tajvidi M, Gardner DJ, Bousfield DW (2016) Cellulose nanomaterials as binders: laminate and particulate systems. J Renew Mater 4:365–376

Toivonen MS, Kurki-Suonio S, Wagermaier W, Hynninen V, Hietala S, Ikkala O (2017) Interfacial polyelectrolyte complex spinning of cellulose nanofibrils for advanced bicomponent fibers. Biomacromol 18:1293–1301

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. In J Appl Polym Sci Appl Polym Symp 37:815–827

Wilhelmy L (1863) Ueber die Abhängigkeit der Capillaritäts‐Constanten des Alkohols von Substanz und Gestalt des benetzten festen Körpers. Annalen der Physik 195(6):177–217

Yousefi Shivyari N, Tajvidi M, Bousfield DW, Gardner DJ (2016) Production and characterization of laminates of paper and cellulose nanofibrils. ACS Appl Mater Interfaces 8:25520–25528

Acknowledgments

This project was supported by the USDA National Institute of Food and Agriculture, McIntire-Stennis. Project# 041616. Maine Agricultural and Forest Experiment Station Publication Number 3622.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghasemi, S., Tajvidi, M., Gardner, D.J. et al. Effect of wettability and surface free energy of collection substrates on the structure and morphology of dry-spun cellulose nanofibril filaments. Cellulose 25, 6305–6317 (2018). https://doi.org/10.1007/s10570-018-2029-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2029-3