Abstract

With increased popularity and technological innovation, more and more electric and electronic equipment wastes (e-wastes) are being generated. Printed circuit boards (PCBs) as fundamental components of electronic wastes, consist of both precious and heavy metals. In this research, the simultaneous extraction Cu and Zn from PCBs used in mobile phones with a natural organic acid and H2O2 was examined. The organic acid was determined from agricultural lemon fruit. The leaching extraction factors investigated include lemon juice concentration, solid/liquid (S/L) ratio, and H2O2 concentration. Response surface methodology (RSM) was applied to optimize the extraction which resulted in the maximum recoveries of 89% Cu and 73% Zn at 1.41% (w/v) S/L ratio, 12.2% (v/v) H2O2, and 74% (v/v) lemon juice after 4 h at 20 °C. The effect of time on the Cu and Zn recoveries at the determined optimum condition was examined. Furthermore, a kinetic study based on a shrinking core model was performed and the result showed that mass diffusion was rate-limiting in the extraction.

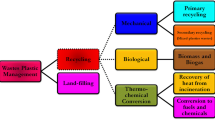

Graphic abstract

Similar content being viewed by others

Abbreviations

- ANOVA:

-

Analysis of variance

- C.I.:

-

Confidence interval

- CCD:

-

Central composite design

- E-wastes:

-

Electronic wastes

- FE-SEM:

-

Field emission scanning electron microscopes

- HPLC:

-

High-performance liquid chromatography

- ICP-OES:

-

Inductively coupled plasma optical emission spectrometer

- PCBs:

-

Printed circuit boards

- RSM:

-

Response surface methodology

- S/L ratio:

-

Solid/liquid ratio

- S/N:

-

Signal to noise

References

Alenezi RA, Al-Fadhli FM (2018) Thermal degradation kinetics of waste printed circuit boards. Chem Eng Res Des 130:87–94

Lee H, Bae M, Lee E, Mishra B (2019) Copper extraction from flue dust of electronic waste by electrowinning and ion exchange process. JOM 71(7):2360–2367

Islam A, Ahmed T, Awual MR, Rahman A, Sultana M, Aziz AA, Monir MU, Teo SH, Hasan M (2019) Advances in sustainable approaches to recover metals from e-waste-a review. J Clean Prod 244:118815

Pradhan JK, Kumar S (2012) Metals bioleaching from electronic waste by Chromobacterium violaceum and Pseudomonads sp. Waste Manag Res 30:1151–1159

Yang H, Zhang S, Ye W, Qin Y, Xu M, Han L (2020) Emission reduction benefits and efficiency of e-waste recycling in China. Waste Manag 102:541–549

Ghimire H, Ariya PA (2020) E-wastes: bridging the knowledge gaps in global production budgets, composition, recycling and sustainability implications. Sustain Chem 1(2):154–182

Sannigrahi S, Suthindhiran K (2019) Metal recovery from printed circuit boards by magnetotactic bacteria. Hydrometallurgy 187:113–124

Arshadi M, Yaghmaei S (2020) Bioleaching of basic metals from electronic waste PCB’s. J Min Mech Eng 1:41–50

Arshadi M, Mousavi SM (2015) Multi-objective optimization of heavy metals bioleaching from discarded mobile phone PCBs: simultaneous Cu and Ni recovery using Acidithiobacillus ferrooxidans. Sep Purif Technol 147:210–219

Mousavi SM, Yaghmaei S, Vossoughi M, Jafari A, Hoseini SA (2005) Comparison of bioleaching ability of two native mesophilic and thermophilic bacteria on copper recovery from chalcopyrite concentrate in an airlift bioreactor. Hydrometallurgy 80:139–144

López-Delgado A, Robla JI, Padilla I, López-Andrés S, Romero M (2020) Zero-waste process for the transformation of a hazardous aluminum waste into a raw material to obtain zeolites. J Clean Prod 255:120178

Mizero B, Musongo T, Rene ER, Battes F, Lens PN (2018) Optimization of process parameters for the chemical leaching of base metals from telecom and desktop printed circuit boards. Process Saf Environ Prot 120:14–23

Jha MK, Kumari A, Choubey PK, Lee JC, Kumar V, Jeong J (2012) Leaching of lead from solder material of waste printed circuit boards (PCBs). Hydrometallurgy 121:28–34

Hosseinzadeh F, Rastegar SO, Ashengroph M, Gu T (2021) Ultrasound-assisted Fenton-like reagent to leach precious metals from spent automotive catalysts: process optimization and kinetic modeling. Int J Environ Sci Technol 1–10

Rahimi G, Rastegar SO, Rahmani F, Gu T (2020) Ultrasound-assisted leaching of vanadium from fly ash using lemon juice organic acids. RSC Adv 10:1685–1696

Hosseinzadeh F, Rastegar SO, Ashengroph M (2021) Bioleaching of rare earth elements from spent automobile catalyst as pretreatment method to improve Pt and Pd recovery: process optimization and kinetic study. Process Biochem 105:1–7

Baniasadi M, Vakilchap F, Bahaloo-Horeh N, Mousavi SM, Farnaud S (2019) Advances in bioleaching as a sustainable method for metal recovery from e-waste: a review. J Ind Eng Chem 76:75–90

Rathna R, Nakkeeran E (2020) Biological treatment for the recovery of minerals from low-grade ores. Current developments in biotechnology and bioengineering. Elsevier, pp 437–458

Rastegar SO, Mousavi SM, Shojaosadati SA, Gu T (2016) Bioleaching of fuel-oil ash using Acidithiobacillus thiooxidans in shake flasks and a slurry bubble column bioreactor. RSC Adv 6:21756

Gu T, Rastegar SO, Mousavi SM, Li M, Zhou M (2018) Advances in bioleaching for recovery of metals and bioremediation of fuel ash and sewage sludge. Bioresour Technol 261:428–440

Liu Q, Bai JF, Gu WH, Peng SJ, Wang LC, Wang JW, Li HX (2020) Leaching of copper from waste printed circuit boards using Phanerochaete chrysosporium fungi. Hydrometallurgy 196:105427

Arshadi M, Mousavi SM (2015) Enhancement of simultaneous gold and copper extraction from computer printed circuit boards using Bacillus megaterium. Bioresour Technol 175:315–324

Esmaeili M, Rastegar SO, Beigzadeh R, Gu T (2020) Ultrasound-assisted leaching of spent lithium ion batteries by naturalorganic acids and H2O2. Chemosphere 254:126670

Hong Eom D, Kwon Kim I, Hyung Han J, Goo Park J (2007) The Effect of hydrogen peroxide in a citric acid based copper slurry on Cu polishing. Electrochem Soc 154:38–44

Jiang F, Chen Y, Ju S, Zhu Q, Zhang L, Peng J, Wang X, Miller JD (2018) Ultrasound-assisted leaching of cobalt and lithium from spent lithium-ion batteries. Ultrason Sonochem 48:88–95

Steer JM, Griffiths AJ (2013) Investigation of carboxylic acids and non-aqueous solvents for the selective leaching of zinc from blast furnace dust slurry. Hydrometallurgy 140:34–41

Kumari A, Jha MK, Singh RP (2016) Recovery of metals from pyrolysed PCBs by hydrometallurgical techniques. Hydrometallurgy 165:97–105

Kim E, Kim M, Lee J, Jeong J, Pandey BD (2011) Leaching kinetics of copper from waste printed circuit boards by electro-generated chlorine in HCl solution. Hydrometallurgy 107:124–132

Xie F, Cai T, Ma Y, Li H, Li C, Huang Z, Yuan G (2009) Recovery of Cu and Fe from printed circuit board waste sludge by ultrasound: evaluation of industrial application. J Clean Prod 17(16):1494–1498

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ozairy, R., Rastegar, S.O., Beigzadeh, R. et al. Optimization of metal bio-acid leaching from mobile phone printed circuit boards using natural organic acids and H2O2. J Mater Cycles Waste Manag 24, 179–188 (2022). https://doi.org/10.1007/s10163-021-01302-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01302-8