Abstract

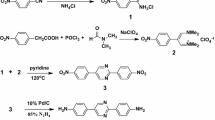

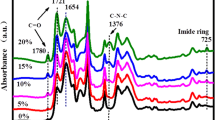

In the family of polyimide (PI) materials, Upilex-S® film has been a shining star through the research PI materials due to its appealing merits. Unfortunately, the wholly rigid-rod backbone and easily formed skin-core micromorphology and microvoids of Upilex-S® type PI lead to the high difficulty in melt- and wet-spinning fabrication. Herein, we propose a facile and scalable method, reaction-spinning, to fabricate the Upilex-S® type PI fiber, in which the rapid solidification of spinning dope and partial imidization take place simultaneously. Thus, the stability and mechanical strength of as-spun fibers can be improved, and the microvoids in fibers can be greatly reduced in relative to the wet-spun fibers. The resultant Upilex-S® type PI fiber shows higher tensile strength and modulus than most commercial thermal-oxidative polymeric fibers with an ultrahigh glass transition temperature Tg of 478 °C. Moreover, the WAXS and SAXS results indicate that orthorhombic crystals are formed for Upilex-S® type PI fiber in the post hot-drawing process. Increasing the hot-drawing temperature results in a continuous crystallization and high orientation of PI chains in amorphous phase and perfects the existing lamellar structure, which make a great contribution to the improved mechanical property.

Similar content being viewed by others

References

Chae, H. G.; Kumar, S. Rigid-rod polymeric fibers. J. Appl. Polym. Sci. 2006, 100, 791–802.

Andres Leal, A.; Deitzel, J. M.; Gillespie, J. W. Assessment of compressive properties of high performance organic fibers. Compos. Sci. Technol. 2007, 67, 2786–2794.

Said, M. A.; Dingwall, B.; Gupta, A.; Seyam, A. M.; Mock, G.; Theyson, T. Investigation of ultra violet (UV) resistance for high strength fibers. Adv. Space. Res. 2006, 37, 2052–2058.

Hu, Z.; Lu, F.; Liu, Y.; Zhao, L.; Yu, L.; Xu, X.; Yuan, W.; Zhang, Q.; Huang, Y. Construction of anti-ultraviolet “shielding clothes” on poly(p-phenylene benzobisoxazole) fibers: metal organic framework-mediated absorption strategy. ACS Appl. Mater. Interfaces 2018, 10, 43262–43274.

Liu, Y.; Liu, Y.; Tan, H.; Wang, C.; Wei, H.; Guo, Z. Structural evolution and degradation mechanism of Vectran® fibers upon exposure to UV-radiation. Polym. Degrad. Stab. 2013, 98, 1744–1753.

Dai, X. M.; Gao, H.; Zhang, R.; Du, Z. J.; Shi, T. F.; Ji, X. L.; Qiu, X. P.; Men, Y. F. Preparation and properties of high-performance polyimide copolymer fibers derived from 5-amino-2-(2-hydroxy-5-aminobenzene)-benzoxazole. Chinese J. Polym. Sci. 2019, 37, 478–492.

Niu, H.; Huang, M.; Qi, S.; Han, E.; Tian, G.; Wang, X.; Wu, D. High-performance copolyimide fibers containing quinazolinone moiety: preparation, structure and properties. Polymer 2013, 54, 1700–1708.

Zhao, Y.; Gao, H.; Li, G. M.; Liu, F. F.; Dai, X. M.; Dong, Z. X.; Qiu, X. P. Synthesis and AO resistant properties of novel polyimide fibers containing phenylphosphine oxide groups in main chain. Chinese J. Polym. Sci. 2019, 37, 59–67.

Zhao, Y.; Li, G. M.; Liu, F. F.; Dai, X. M.; Dong, Z. X.; Qiu, X. P. Synthesis and properties of novel polyimide fibers containing phosphorus groups in the side chain (DATPPO). Chinese J. Polym. Sci. 2017, 35, 372–385.

Zhang, M.; Niu, H.; Wu, D. Polyimide fibers with high strength and high modulus: preparation, structures, properties, and applications. Macromol. Rapid Commun. 2018, 39, 1800141.

Liaw, D. J.; Wang, K. L.; Huang, Y. C.; Lee, K. R.; Lai, J. Y.; Ha, C. S. Advanced polyimide materials: syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974.

Maier, G. Low dielectric constant polymers for microelectronics. Prog. Polym. Sci. 2001, 26, 3–65.

Fang, Y.; Dong, J.; Zhang, D.; Zhao, X.; Zhang, Q. Preparation of high-performance polyimide fibers via a partial pre-imidization process. J. Mater. Sci. 2019, 54, 3619–3631.

Gan, F.; Dong, J.; Tang, M.; Li, X.; Li, M.; Zhao, X.; Zhang, Q. High-tenacity and high-modulus polyimide fibers containing benzimidazole and pyrimidine units. React. Funct. Polym. 2019, 141, 112–122.

Strobl, G. R.; Schneider, M. J.; Voigt-Martin, I. G. Model of partial crystallization and melting derived from small-angle X-ray scattering and electron microscopic studies on low-density polyethylene. J. Polym. Sci., Part B: Polym. Phys. 1980, 18, 1361–1381.

Shaiju, P.; Murthy, N. S.; Gowd, E. B. Molecular, crystalline, and lamellar length-scale changes in the poly(L-lactide) (PLLA) during cyclopentanone (CPO) desorption in PLLA/CPO cocrystals. Macromolecules 2016, 49, 224–233.

Seo, Y.; Lee, S. M.; Kim, D. Y.; Kim, K. U. Kinetic study of the imidization of a poly(ester amic acid) by FT-Raman spectroscopy. Macromolecules 1997, 30, 3747–3753.

Sun, G.; Zhang, M.; Chen, N.; Niu, H.; Qi, S.; Wu, D. Fabrication of ultrahigh-strength polybenzimidazole fibers via a novel and green integrated liquid crystal spinning process. Macromol. Mater. Eng. 2020, 305, 1900717.

Gu, H. Research on thermal properties of Nomex/Viscose FR fibre blended fabric. Mater. Design. 2009, 30, 4324–4327.

Luan, J.; Zhang, S.; Geng, Z.; Wang, G. Influence of the addition of lubricant on the properties of poly(ether ether ketone) fibers. Polym. Eng. Sci. 2013, 53, 2254–2260.

Li, H.; Zhu, Y.; Xu, B.; Wu, C.; Zhao, J.; Dai, M. Preparation and characterization of all para-position polysulfonamide fiber. J. Appl. Polym. Sci. 2013, 127, 342–348.

Yang, F.; Bai, Y.; Min, B. G.; Kumar, S.; Polk, M. B. Synthesis and properties of star-like wholly aromatic polyester fibers. Polymer 2003, 44, 3837–3846.

Xu, Y.; Wang, S.; Li, Z.; Xu, Q.; Zhang, Q. Polyimide fibers prepared by dry-spinning process: imidization degree and mechanical properties. J. Mater. Sci. 2013, 48, 7863–7868.

Luo, L.; Pang, Y.; Jiang, X.; Wang, X.; Zhang, P.; Chen, Y.; Peng, C.; Liu, X. Preparation and characterization of novel polyimide films containing amide groups. J. Polym. Res. 2011, 19, 9783.

Ishige, R.; Masuda, T.; Kozaki, Y.; Fujiwara, E.; Okada, T.; Ando, S. Correction to precise analysis of thermal volume expansion of crystal lattice for fully aromatic crystalline polyimides by X-ray diffraction method: relationship between molecular structure and linear/volumetric thermal expansion. Macromolecules 2017, 50, 2599–2600.

Yoon, D. Y.; Parrish, W.; Depero, L. E.; Ree, M. Chain conformations of aromatic polvimides and their ordering in thin films. MRS Proceedings 2011, 227, 387.

Ishige, R.; Masuda, T.; Kozaki, Y.; Fujiwara, E.; Okada, T.; Ando, S. Precise analysis of thermal volume expansion of crystal lattice for fully aromatic crystalline polyimides by X-ray diffraction method: Relationship between molecular structure and linear/volumetric thermal expansion. Macromolecules 2017, 50, 2112–2123.

Northolt, M. G.; Hout, R. V. D. Elastic extension of an oriented crystalline fibre. Polymer 1985, 26, 310–316.

Murthy, N. S.; Bednarczyk, C.; Moore, R. A. F.; Grubb, D. T. Analysis of small-angle X-ray scattering from fibers: structural changes in nylon 6 upon drawing and annealing. J. Polym. Sci., Part B Polym. Phys. 1996, 34, 821–835.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51903038, 21774019, and 21975040), the Program of Shanghai Academic Research Leader (No. 18XD1400100) and the Scientific Research Innovation Plan of Shanghai Education Commission (No. 2019-01-07-00-03-E00001).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Information

Rights and permissions

About this article

Cite this article

Zheng, SS., Dong, H., Wang, SH. et al. Scalable Reaction-spinning of Rigid-rod Upilex-S® Type Polyimide Fiber with an Ultrahigh Tg. Chin J Polym Sci 39, 592–600 (2021). https://doi.org/10.1007/s10118-021-2508-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-021-2508-0