Abstract

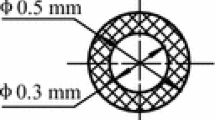

In the paper, the effects of die swell and gas flow rate of polymer multi-lumen micro tubes on the design of the cross-section of the multi-lumen die are investigated mainly. On the one hand, the effects of die swell on the design of the cross-section of the extrusion die are studied on the basis of the function of die swell, extrusion velocity and length–diameter ratio of the die. After analysis, it is found that the die swell phenomenon is obvious especially when the micro tube is extruded with larger wall thickness at a higher extrusion velocity, which may lead to the deformation of the extruded tube. For extrusion of micro tubes with a well-defined shape, there is a need to optimize the geometries of the die accordingly to compensate this deformation. According to the analysis, a double-lumen and a five-lumen micro extrusion die are designed and manufactured separately. On the other hand, the extrusion experiments on the effects of gas flow rate of polymer multi-lumen micro tubes on the design of the cross-section of the multi-lumen die are conducted using the extrusion dies. Considering the effects of die swell and the gas flow rate of extrusion processes on the tubes, it is found that a well-defined multi-lumen micro tube can only be successfully fabricated by combining all the three factors including the effect of die swell, gas flow rate and optimization of the cross-section of the extrusion die.

Similar content being viewed by others

References

Chen CS, Chen SC, Liaw WL (2008) Rheological behavior of POM polymer melt flowing through micro-channels. Eur Polym J 44(6):1891–1898

Debbaut B, Marchal T (2013) Numerical simulation of extrusion process and die design for industrial profile, using multimode pom–pom model. Plast Rubber Compos 37(2–4):142–150

Gu DZ (1988) Polymer fluid dynamics. Sichuan Education Press, China

Hogan TA, Walia P, Dems BC (2009) Investigation of the relationships between die build up and die swell. Polym Eng Sci 49(2):333–343

Kalyon D, Tan V, Kamal MR (1980) The dynamics of parison development in blow molding. Polym Eng Sci 20(12):773–777

Liang J (1995) Research on extrusion swell behaviour of blastomers through short dies. China Elastom 5(4):43–45

Liu F (2003) The die design for extrusion processing. Die Mould Technol 3:32–33

Niranchana R (2005) Validation of a program that simulates flow in an extrusion die. M. Eng thesis. University of Massachusetts Lowell, USA

Pauli L, Behr M, Elgeti S (2013) Towards shape optimization of profile extrusion dies with respect to homogeneous die swell. J Nonnewton Fluid Mech 200(20):79–87

Rean DC, Wen RJ, Shia CC (2005) Study on rheological behavior of polymer melt flowing through micro-channels considering the wall-slip effect. J Micromech Microeng 15:1389–1396

Sheptak N, Beyer CE (1965) Know your parison. SPE J 21:190–196

Sombatsompop N, Intawong NT (2005) A comparative study on extrudate swell ratio of polystyrene in a capillary rheometer and a single screw extruder. Polym Test 24(8):948–952

Tang ZY (1991) Application of rheology in engineering design of plastics die and mold. National Defense Industry Press, China

Tang ZY (2000) Optimization design of plastics extrusion and injection mold. China Machine Press, China

Tian H, Zhao D, Wang M, Jin G, Jin Y (2015) Study on extrudate swell of polypropylene in double-lumen micro profile extrusion. J Mater Process Technol 225:357–368

Wu DM, Liu Y, Guo YC (2006) The application prospects of precision medical plastic catheter. Plast Manuf 6:38–44

Xiao JH, Liu HS, Xing YH (2009) Slip length of gas-assisted extrusion die influence on die swell ratio. Plastics 38(1):115–117

Xu PX (2003) Polymer rheology and its application. Chemical Industry Press, China

Xu B, Wang MJ, Yu TM, Zhao DY (2009) A study of novel viscous dissipation measurement for polymer melts in microchannels. J Mech Eng Sci 224(C9):2027–2039

Yang AC (1999) Extrusion die technology for plastic profile. Machinery Industry Press, China

Yin CF (2007) Control of the ellipticity and the outer wall thickness of the high pressure pipe. Pet Chem Constr 29(4):63–64

Zhao LZ (2005) Theoretical analysis on polymer melt extrusion swell at conical die with different entrance angles. China Plast Ind 33(1):116–118

Zhao DY, Wang MJ, Li K, Song MC, Jin YF (2010) Flow uniformity of polymer micro extrusion processing. Polym Mater Sci Eng 26(7):159–162

Zou WD (2006) Study on extrusion processing of profile pipe with small cross-section. M. Eng thesis. Beijing University of Chemical Technology, China

Acknowledgements

This paper was supported by the Provincial Natural Science Foundation of Anhui Universities (Grant No. KJ2015A225), the Science Research Funds of Chaohu College (Grant No. XLY-201420), and the PhD Science Research Funds of Chaohu College (Grant No. KYQD-201404).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, G., Jin, Y., Zhao, D. et al. Cross-section design of multi-lumen extrusion dies: study on the effects of die swell and gas flow rate of the lumen. Microsyst Technol 23, 5093–5104 (2017). https://doi.org/10.1007/s00542-017-3489-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3489-3