Abstract

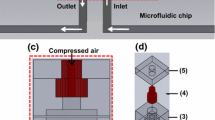

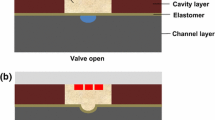

A hybrid valve for lab on chip applications is presented. The valve is assembled by bonding poly (methyl methacrylate), PMMA, and silicon-based elastomers. The process used to promote the hybrid bonding includes the deposition of an organosilane (TMSPM) on the thermoplastic polymer, PMMA to interface PMMA and elastomers. For this study, a membrane in ELASTOSIL® is bonded in correspondence of the end of two microfluidic channels of a fabricated PMMA microfluidic chip. Prior the bonding, a plasma etching process has been used to remove the TMSPM in a confined circular area. This process made possible to bond selectively the edge of a membrane leaving free to move its central part. Actuating the membrane with an external positive pressure or vacuum is possible, respectively, to obstruct or to connect the microfluidic channels. The microvalve may be simply integrated in microfluidic devices and permits the control of microvolumes of fluid in processes such as transport, separation, and mixing. The deposition of the TMSPM, the bonding of the valve and its actuation has been characterized and tested. The flow rate control of liquids through the valve has been characterized. The results have been discussed and commented. The valve can stand up to 14 psi without showing leakages.

Similar content being viewed by others

References

Becker P, Locascio LE (2002) Polymer microfluidic devices. Talanta 56:267–287. doi:10.1016/S0039-9140(01)00594-X

Chakraborty I, Tang WC, Bame DP, Tang TK (2000) MEMS micro-valve for space applications. Sens Actuators 83:188–193. doi:10.1016/S0924-4247(99)00382-9

El-Ali J, Sorger PK, Jensen KF (2006) Cells on chips. Nature 442:403–411. doi:10.1038/nature05063

Jensen KF (2001) Microreaction engineering––is small better? Chem Eng Sci 56:293–303. doi:10.1016/S0009-2509(00)00230-X

Nguyen NT, Truong TQ, Wong KK, Ho SS, Low LN (2004) Micro check valves for integration into polymeric. Microfluidic devices. J Micromech Microeng 14:69–75. doi:10.1088/0960-1317/14/1/309

Perozziello G (2008) Packaging of microfluidic systems. In: Geschke O, Klank H, Telleman P (eds) Microsystem engineering of lab-on-a-chip devices, 2nd edn. Wiley, pp 193–219

Perozziello G, Snakenborg D, Zhang Z, Kutter JP, Geschke O, Jensen KF (2006) A fluidic motherboard including fluidic and optical interconnections, having modular functionality for optical analysis in microfluidic systems. In: Proceedings μTAS 2006

Simone G, Perozziello G, Szita N, Tagliaferri V (2006) Synthesis and characterization of tunable highly transparent nanocomposites: an in-depth experimental analysis oriented to the fabrication of waveguides. In: Proceedings MRS spring conference 2006, Boston

Snakenborg D, Perozziello G, Klank H, Geschke O, Kutter JP (2006) Direct milling and casting of polymer-based optical waveguides for improved transparency in the visible range. J Micromech Microeng 16:375–381. doi:10.1088/0960-1317/16/2/023

Toh AGG, Wang ZF, Ng SH (2008) Fabrication of embedded microvalve on PMMA microfluidic devices through surface functionalization, submitted on behalf of EDA Publishing Association. In: Dans symposium on design, test, integration and packaging of MEMS/MOEMS-DTIP 2008, Nice

Unger MA, Chou HP, Thorsen T, Scherer A, Quake SR (2000) Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 288:113–116. doi:10.1126/Science.290.5496.1536

Acknowledgments

We acknowledge the software team of Silicon Biosystems which developed the software for controlling the experimental set-up and the hardware team which developed the electronic hardware for controlling the experimental set-up.

Author information

Authors and Affiliations

Corresponding author

Additional information

G. Simone and G. Perozziello contributed equally.

Rights and permissions

About this article

Cite this article

Simone, G., Perozziello, G., Sardella, G. et al. A microvalve for hybrid microfluidic systems. Microsyst Technol 16, 1269–1276 (2010). https://doi.org/10.1007/s00542-009-0986-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-009-0986-z