Abstract

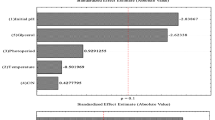

Oxalic acid has potent nematicidal activity against the root-knot nematode Meloidogyne incognita. In this study, fermentation parameters for oxalic acid production in submerged culture of Aspergillus niger F22 at 23, 25, and 30 °C were optimized in 5-L jar fermenters. The viscosity of the culture broth increased with increasing temperature. There was a negative correlation between oxalic acid production and the apparent viscosity; high volumetric productivity of oxalic acid was obtained at low apparent viscosity (less than 1000 cP), with a productivity of more than 100 mg/L h. When the apparent viscosity was over 2500 cP, the volumetric productivity decreased below 50 mg/L h. In addition, the volumetric mass transfer coefficient, K L a, positively correlated with volumetric productivity. When the K L a value increased from 0.0 to 0.017 /s, the volumetric productivity proportionally increased up to 176 mg/L h. When the temperature decreased, K L a increased due to the decrease in viscosity, leading to increased volumetric productivity. The highest productivity of 7453.3 mg/L was obtained at the lowest temperature, i.e., 23 °C. The nematicidal activity of culture filtrate was proportional to the content of oxalic acid. Based on a constant impeller tip speed, oxalic acid production was successfully scaled up to a 500-L pilot vessel, producing a final concentration comparable to that in the 5-L jar.

Similar content being viewed by others

References

Affokpon A, Coyne DL, Htay CC, Agbede RD, Lawouin L, Coosemans J (2011) Biocontrol potential of native Trichoderma isolates against root-knot nematodes in West African vegetable production systems. Soil Biol Biochem 13:600–608

Zhang S, Gan Y, Xu B (2015) Biocontrol potential of a native species of Trichoderma longibrachiatum against Meloidogyne incognita. Appl Soil Ecol 94:21–29

Sikora RA, Fernàndez E (2005) In: Luc M, Sikora RA, Bridge J (eds) Plant parasitic nematodes in subtropical and tropical agriculture, vol II. CAB International, Wallingford

Sasser JN, Carter CC (1985) In: Sasser JN, Carter CC (eds) An advanced treatise on Meloidogyne. North Carolina State University Graphics, Raleigh

Milligan SB, Bodeau J, Yaghoobi J, Kaloshian I, Zabel P, Williamson VM (1998) The root knot nematode resistance gene Mi from tomato is a member of the leucine zipper, nucleotide binding, leucine-rich repeat family of plant genes. Plant Cell 10:1307–1320

Mayer A, Anke H, Sterner O (1997) Omphalotin, a new cyclic peptide with potent nematicidal activity from Omphalotus olearius I. Fermentation and biological activity. Nat Prod Lett 10:25–32

Hu Y, Zhang W, Zhang P, Ruan W, Zhu X (2012) Nematicidal activity of chaetoglobosin A produced by Chaetomium globosum NK102 against Meloidogyne incognita. J Agric Food Chem 61:41–46

Stadler M, Anke H, Sterner O (1993) Linoleic acid - the nematicidal principle of several nematophagous fungi and its production in trap-forming submerged cultures. Arch Microbiol 160:401–405

Jang JY, Choi YH, Shin TS, Kim TH, Shin KS, Park HW, Kim YH, Kim H, Choi GJ, Jang KS, Cha B, Kim IS, Myung EJ, Kim JC (2016) Biological control of Meloidogyne incognita by Aspergillus niger F22 producing oxalic acid. PLOS One 11:e0156230

Blanch HW, Bhavara SM (1976) Non-Newtonian fermentation broths: rheology and mass transfer. Biotechnol Bioeng 18:745–790

Buckland BC, Gwewonyo K, Dimasi D, Hung G, Westerfield G, Nienow AW (1998) Improved performance in viscous mycelial fermentations by agitator retrofitting. Biotechnol Bioeng 31:737–742

Karsheva M, Hristov J, Penchev I, Lossev V (1997) Rheological behavior of fermentation broths in antibiotic industry. Appl Biochem Biotechnol 68:187–206

Kim HJ, Kim JH, Oh HJ, Shin CS (2002) Morphological control of Monascus cells and scale-up of pigment fermentation. Process Biochem 38:649–655

Cho YJ, Hwang HJ, Kim SW, Song CH, Yun JW (2002) Effect of carbon source and aeration rate on broth rheology and fungal morphology during red pigment production by Paecilomyces sinclairii in a batch bioreactor. J Biotechnol 95:13–23

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Bandyopadhyay B, Humphrey AE (1967) Dynamic measurement of the volumetric oxygen transfer coefficient in fermentation systems. Biotechnol Bioeng 9:533–544

Park HW, Kim HH, Youn SY, Shin TS, Bilgrami AL, Cho MR, Shin CS (2012) Biological control potentials of insect-parasitic nematode Rhabditis blumi (Nematoda: Rhabditida) for major cruciferous vegetable insect pests. Appl Entomol Zool 47:389–397

Abbott WS (1987) A method of computing the effectiveness of and insecticide. 1925. J Am Mosq Control Assoc 3:302–303

Kim HJ, Kim YH, Roh YH, Seong BL, Shin CS (2005) Optimization of enterokinase fermentation using a recombinant Saccharomyces cerevisiae. Process Biochem 40:717–722

Ardestani F, Fatemi SS, Yakhchali B, Hosseyni SM, Najafpour G (2010) Evaluation of mycophenolic acid production by Penicillium brevicompactum MUCL 19011 in batch and continuous submerged cultures. Biochem Eng J 50:99–103

Gehrig I, Bart HJ, Anke T, Germerdonk R (1998) Influence of morphology and rheology on the production characteristics of the basidiomycete Cyathus striatus. Biotechnol Bioeng 59:525–533

Ahn J, Jung J, Hyung W, Haam S, Shin CS (2006) Enhancement of monascus pigment production by the culture of Monascus sp. J101 at low temperature. Biotechnol Prog 22:338–340

Pazouki M, Panda T (2000) Understanding the morphology of fungi. Bioprocess Eng 22:127–143

Ha S, Lee KJ, Lee SI, Gwak HJ, Lee JH, Kim TW, Choi HJ, Jang JY, Choi JS, Kim CJ, Kim HH, Park HW (2017) Optimization of herbicidin A production in submerged culture of Streptomyces scopuliridis M40. J Microbial Biotechnol 27:947–955

Djian C, Pijarowski L, Ponchet M, Arpin N, Favre-Bonvin J (1991) Acetic acid: a selective nematicidal metabolites from culture filtrates of Paecilomyces lilacinus (Thom) Samson and Trichoderma longibrachiatum Rifai. Nematologica 37:101–112

Seo Y, Kim YH (2014) Control of Meloidogyne incognita using mixture of organic acids. Plant Pathol J 30:450–455

Zuckerman BM, Matheny M, Acosta N (1994) Control of plant-parasitic nematodes by a nematicidal strain of Aspergillus niger. J Chem Ecol 20:33–43

Garcia-Ochoa F, Castro EG, Santos V (2000) Oxygen transfer and uptake rates during xanthan gum production. Enzyme Microb Technol 27:680–690

Shin WS, Lee D, Kim S, Jeong YS, Chun GT (2013) Application of scale-up criterion of constant oxygen mass transfer coefficient (kLa) for production of itaconic acid in a 50 L pilot-scale fermentor by fungal cells of Aspergillus terreus. J Microbiol Biotechnol 23:1445–1453

Mayr B, Nagy E, Horvat P, Moser A (1994) Scale-up on basis of structured mixing models: a new concept. Biotechnol Bioeng 43:195–206

Junker B, Reddy J, Olewinski R, Gailliot P, Byrne K, Gbewonyo K (1998) Secondary metabolite scale-up to minimize homolog impurity levels. Biotechnol Bioeng 59:595–604

Acknowledgements

This research was supported by grants from the Rural Development Administration (PJ01020703) and the World Institute of Kimchi (KE1701-1), funded by the Ministry of Science, ICT, and Future Planning, Republic of Korea.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors of this manuscript declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Lee, S.I., Lee, K.J., Chun, H.H. et al. Process development of oxalic acid production in submerged culture of Aspergillus niger F22 and its biocontrol efficacy against the root-knot nematode Meloidogyne incognita . Bioprocess Biosyst Eng 41, 345–352 (2018). https://doi.org/10.1007/s00449-017-1867-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-017-1867-y