Abstract

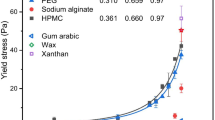

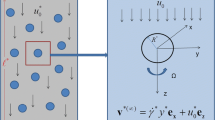

Experimental measurements of non-colloidal multimodal suspension viscosities are performed over a wide range of mixing ratios and used to test the robustness and predictive capability of a recent viscosity model (Mwasame et al. in Phys Fluids 28:061701, 2016b), subsequently referred to as the MWB model. Three unimodally distributed particle suspensions with narrow size distributions are blended to make the bimodal and trimodal suspensions used in the rheological experiments. We demonstrate how predictions for mixture viscosities can be made using the MWB model only requiring the volume-weighted average particle sizes and viscosity correlations of the individual unimodal suspensions comprising the blend. The resultant model predictions are found to be in good agreement with measured bimodal and trimodal viscosity data to within expected experimental uncertainty. The datasets provided here can be used to validate future modeling efforts, and the MWB model can be used to optimize the viscosity of multimodal suspension mixtures for specific performance criteria.

Similar content being viewed by others

Notes

The Shields parameter Ψ is calculated as Ψ = τ/Δρga where τ is the shear stress, Δρ is the difference in the density of the suspended particle and the suspension medium, g is the gravitational acceleration, and a is the radius of the particle.

References

Chang C, Powell RL (1994) Effect of particle size distributions on the rheology of concentrated binary suspensions. J Rheol 38:85–98

Chong JS, Christiansen EB, Baer AD (1971) Rheology of concentrated suspensions. J Appl Polym Sci 15:2007–2021

Dörr A, Sadiki A, Mehdizadeh A (2013) A discrete model for the apparent viscosity of polydisperse suspensions including maximum packing fraction. J Rheol 57:743–765

Einstein A (1906) A new determination of molecular dimensions. Ann Phys 324:289–306

Einstein A (1911) A new determination of molecular dimensions. Ann Phys 339:591–592

Faroughi SA, Huber C (2014) Crowding-based rheological model for suspensions of rigid binary-sized particles with interfering size ratios. Phys Rev E 90:052303

Farr RS (2014) Simple heuristic for the viscosity of polydisperse hard spheres. J Chem Phys 141:214503

Farris RJ (1968) Prediction of the viscosity of multimodal suspensions from monodisperse viscosity data. Trans Soc Rheol 12:281–301

Furnas CC (1931) Grading aggregates-I—mathematical relations for beds of broken solids of maximum density. Ind Eng Chem 23:1052–1058

Maron SH, Pierce PE (1956) Application of Ree-Eyring generalized flow theory to suspensions of spherical particles. J Colloid Sci 11:80–95

Mewis J, Wagner NJ (2012) Colloidal suspension rheology. Cambridge University Press

Mooney M (1951) The viscosity of a concentrated suspension of spherical particles. J Colloid Sci 6:162–170

Mwasame PM, Wagner NJ, Beris AN (2016a) Modeling the effects of polydispersity on the viscosity of noncolloidal hard sphere suspensions. J Rheol 60:225–240

Mwasame PM, Wagner NJ, Beris AN (2016b) Modeling the viscosity of polydisperse suspensions: improvements in prediction of limiting behavior. Phys Fluids 28:061701

Ouchiyama N, Tanaka T (1984) Porosity estimation for random packings of spherical particles. Ind Eng Chem Fundam 23:490–493

Qi F, Tanner R (2012) Random close packing and relative viscosity of multimodal suspensions. Rheol Acta 51:289–302

Shewan HM, Stokes JA (2015) Viscosity of soft spherical micro-hydrogel suspensions. J Colloid Interface Sci 442:75–81

Wagner NJ, Woutersen AM (1994) The viscosity of binary and polydisperse suspensions of hard spheres in the dilute limit. J Fluid Mech 278:267–287

Zarraga IE, Hill DA, Leighton DT (2000) The characterization of the total stress of concentrated suspensions of noncolloidal spheres in Newtonian fluids. J Rheol 44:185–220

Acknowledgements

This material is based upon work supported by the National Science Foundation under Grant No. CBET 312146. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 14692 kb)

Appendices

Appendix 1

This appendix summarizes the data on the experimentally determined particle size distributions. The data in Table 4 correspond to the sizes determined from the microscopy images processed using ImageJ software. The volume-weighted average sizes reported in Table 2 are computed from this data.

Appendix 2

This appendix summarizes the calculations used to determine the volume fractions, density, and error bars in Fig. 3. The values of the volume fraction reported in this paper are nominal volume fractions. This section describes the process by which error was propagated to obtain the unimodal viscosity correlations in Fig. 2. For accuracy, all the suspensions were prepared on a gravimetric basis to ensure maximum accuracy. The determination of the error in the volume fractions starts with determining the density of the particles and PEG-200 medium. For this, volumetric flasks with a given uncertainty as well as a Fisher Scientific analytical balance were used. By determining the densities of the particles and medium by carrying out multiple replica experiments, the density and the associated error in its value are determined—see Table 5. Knowing the uncertainty in the micro-balance measurements as well as the density measurements on both the PEG-200 and the particles allowed for error to be further propagated to the level of the volume fractions at the stock solutions and the subsequent dilutions of the stock solution. The individual errors propagated for the volume fraction result in the horizontal error bars—see last two columns of Table 6.

Rights and permissions

About this article

Cite this article

Mwasame, P.M., Mertz, C.A., Rosario, E.J. et al. An experimental study of multimodal glass suspension rheology to test and validate a polydisperse suspension viscosity model. Rheol Acta 56, 995–1006 (2017). https://doi.org/10.1007/s00397-017-1050-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-017-1050-z