Abstract

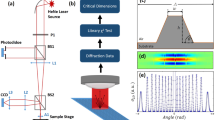

In this paper we discuss the application of NDSE [1] (Hewlett Packard’s nanoscale displacement sensing and estimation technology) as an overlay metrology tool. We describe a method where nanoscale displacement sensing forms the basis of a precision alignment measurement. We will then provide a review of experiments performed to assess the accuracy of one particular NDSE algorithm, tracking silicon targets as they translate on a piezoelectric stage under an optical microscope. We conclude by describing upcoming experiments which will incorporate NDSE as an alignment sensor in a nanoimprint lithography application.

Current methods of overlay metrology and many methods of displacement metrology require precise alignment targets, such as symmetric geometric figures or extremely high-Q diffraction gratings. Such patterns are expensive to produce and/difficult to fabricate consistently. On the other hand, NDSE provides displacement sensing by tracking totally arbitrary patterns. As long as the patterns remain fixed, NDSE can provide extraordinary precision. We extend this advantage into a method for alignment sensing, which retains displacement sensing as the key underlying measurement. Hence, as with displacement sensing, the alignment targets need not be held to any absolute standard, pattern asymmetries caused by process variations are not an issue, and precision gratings are not required.

Similar content being viewed by others

References

J. Gao, C. Picciotto, W. Jackson: Appl. Phys. A, DOI: 10.1007/s00339-004-3153-5 (2005)

Y. Chen, G.Y. Jung, D.A.A. Ohlberg, X. Li, D.R. Stewart, J.O. Jeppesen, K.A. Nielsen, J.F. Stoddart, R.S. Williams: Nanotechnology 14, 462 (2003)

M.-T. Li, L. Chen, S.Y. Chou: Appl. Phys. Lett. 78, 3322 (2001)

R. DeJule: A Look at Overlay Error, Semiconductor international, Newton, 23, 52 (2000)

A. Starikov: Metrology of image placement, AIP Conf. Proc. 449, 513 (1998)

N.T. Sullivan: Critical issues in overlay metrology, AIP Conf. Proc. 550, 346 (2001)

N.T. Sullivan, J. Shin: Overlay metrology: the systematic, the random and the ugly, AIP Conf. Proc. 449, 502 (1998)

J.N. Helbert: Handbook of VLSI Microlithography: Principles, Technology, and Applications, 2nd ed., Park Ridge, N.J.: Noyes Publications; Norwich, N.Y.: William Andrew Pub., (2001) pp. 420–436,

X. Chen, A.A. Ghazanfarian, M.A. McCord, R.F.W. Pease: J. Vac. Sci. Technol. B 16, 3637 (1998)

S. Mayo, J.J. Kopanski, W.F. Guthrie: Intermittent-contact scanning capacitance microscopy imaging and modeling for overlay metrology, AIP Conf. Proc. 449, 567 (1998)

W. Zhang, S.Y. Chou: Appl. Phys. Lett. 79, 845 (2001)

E.E. Moon, L. Chen, N.P. Everett, M.K. Mondol Mark, H.I. Smith: J. Vac. Sci. Technol. B 21, 3112 (2003)

A. Feigel, Z. Kotler, B. Sfez: Opt. Lett. 27, 746 (2002)

H. Ryoichi, H. Tatsuhiko, N. Hiroshi, K. Osamu, N. Takeshi, U. Norio: J. Vac. Sci. Technol. B 12, 3247 (1994)

H. Zhou, M. Feldman, R. Bass: J. Vac. Sci. Technol. B 12, 3261 (1994)

S. Sohail, H. Naqvi, S.H. Zaidi, S.R.J. Brueck, J.R. McNeil: J. Vac. Sci. Technol. B 12, 3600 (1994)

D.L. White, O.R. Wood II: J. Vac. Sci. Technol. B 18, 3552 (2000)

G.L. Brown: ACM Computing Surveys. 24, 325 (1992)

C.-F. Chen, R.L. Engelstad, E.G. Lovell, D.L. White, O.R. Wood II, M.K. Smith, L.R. Harriott: J. Vac. Sci. Technol. B 20, 3099 (2002)

C.D. Schaper, B.-D.Chen, R.F.W. Pease: Rev. Sci. Instrum. 75, 1997 (2004)

C.D. Schaper: J. Microlithogr., Microfabr., Microsyst. 3, 174 (2004)

F.-M. Wang, R.F.W. Pease: J. Vac. Sci. Technol. B 22, 12 (2004)

V. Boegli, D.P. Kern: J. Vac. Sci. Technol. B 8, 1994 (1990)

http: //www.pixelprofile.com/

H. Stone, M. Orchard, E.-C. Chang: Subpixel registration of images. Conference record of the thirty-third asilomar conference on signals, systems, and computers (Cat. No.CH37020). IEEE, Piscataway, NJ, USA. 2 (1999) pp. 1446–52

S.Y. Chou, P.R. Krauss , P.J. Renstrom: J. Vac. Sci. Technol. B 14, 4129 (1996)

International Technology Roadmap For Semiconductors (2003), SIA (Semiconductor Industry Association)

L.J. Guo: J. Phys. D: Appl. Phys. 11, R123 (2004)

J.T. Hastings, F. Zhang, M.A. Finlayson, J.G. Goodberlet, H.I. Smith: J. Vac. Sci. Technol. B 18, 3268 (2000)

N. Li, W. Wu, S.Y. Chou: Sub-100 nm alignment accuracy in nanoimprint lithography using moiré fringe method, Second International Conference on Nanoimprint and Nanoprint Technology, Boston (2003)

Thanks to Will Tong of Hewlett Packard/Corvallis for CAD design of mold

J. Ertel, W.D. Holland, K.D. Vincent, R. Jamp, R.R. Baldwin: Substrate advance measurement system using cross-correlation of light sensor array signals, United States Patent No. 5,149,980, 1991

B. Tullis, L. McColloch: Method of correlating immediately acquired and previously stored feature information for motion sensing, US Patent No. 6,222,174, 1999

R. Beausoleil, R. Allen: Navigation system for handheld scanner, US Patent No. 6,195,475, 2001

C. Picciotto, J. Gao: Displacement estimation system and method, US patent pending, Hewlett Packard internal docket number 200403695

C. Picciotto, J. Gao: Displacement estimation system and method, US patent pending, Hewlett Packard internal docket number 200403700

C. Picciotto, J. Gao, W. Wu: Displacement estimation system and method, US patent pending, Hewlett Packard internal docket number 200403527

C. Picciotto, J. Gao: Displacement measurements using phase changes, US patent pending, Hewlett Packard internal docket number 200401942

C. Picciotto, J. Gao: Measuring sub-wavelength image displacements, US patent pending, Hewlett Packard internal docket number 200400345

Author information

Authors and Affiliations

Corresponding author

Additional information

PACS

06.30.Bp; 06.60.Sx; 81.16.-c; 81.16.Nd

Rights and permissions

About this article

Cite this article

Picciotto, C., Gao, J., Hoarau, E. et al. Image displacement sensing (NDSE) for achieving overlay alignment. Appl. Phys. A 80, 1287–1299 (2005). https://doi.org/10.1007/s00339-004-3152-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-004-3152-6