Abstract

Nanostructured thermoelectric Bi2Te3 powders with various morphologies were hydrothermally synthesized using different precursors and routes to give an experimental comprehension on the formation of the nanopowders. It was found that the polyhedral Bi2Te3 particles are formed by surface nucleation in a continuous nucleation process, the hexagonal Bi2Te3 thin sheets are formed in a nucleus saturation process due to the anisotropic growth of the crystals, and the mono-atom reaction model leads to irregular bent thin Bi2Te3 sheets. Some quasi one-dimensional nanorods and nanotubes were also found in the synthesized Bi2Te3 powders.

Similar content being viewed by others

References

F.J. DiSalvo: Science 285, 703 (1999)

B.S. Sales: Science 295, 1248 (2002)

G.A. Slack, V.G. Tsoukala: J. Appl. Phys. 76, 1665 (1994)

T.M. Tritt: Science 283, 804 (1999)

B.C. Sales, D. Mandrus, R.K. Williams: Science 272, 1325 (1996)

G.S. Nolas, D.G. Vanderveer, A.P. Wilkinson, J.L. Cohn: J. Appl. Phys. 91, 8970 (2002)

M.S. Sander, A.L. Prieto, R. Gronsky, T. Sands, A.M. Stacy: Adv. Mater. 14, 665 (2002)

M. Martín-González, A.L. Prieto, R. Gronsky, T. Sands, A.M. Stacy: Adv. Mater. 15, 1003 (2003)

R. Venkatasubramanian, E. Siivola, T. Colpitts, B. O’Quinn: Nature 413, 597 (2001)

T.C. Harman, P.J. Taylor, M.P. Walsh, B.E. LaForge: Science 297, 2229 (2002)

S.H. Yu, J. Yang, Y.S. Wu, Z.H. Han, J. Lu, Y. Xie, Y.T. Qian: J. Mater. Chem. 8, 1949 (1998)

Y. Deng, X.S. Zhou, G.D. Wei, J. Liu, C.W. Nan, S.J. Zhao: J. Phys. Chem. Solids 63, 2119 (2002)

M.A. Meitl, T.M. Dellinger, P.V. Braun: Adv. Funct. Mater. 13, 795 (2003)

Y. Deng, G.D. Wei, C.W. Nan: Chem. Phys. Lett. 368, 639 (2003).

Y. Deng, C.W. Nan, G.D. Wei, L. Guo, Y.H. Lin: Chem. Phys. Lett. 374, 410 (2003)

X.B. Zhao, Y.H. Zhang, X.H. Ji: Inorg. Chem. Comm. 7, 386 (2004)

X.B. Zhao, X.H. Ji, Y.H. Zhang, B.H. Lu: J. Alloys Compd. 368, 349 (2004)

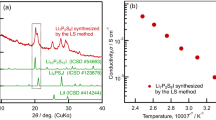

JCPDS-ICDD 1999, International Centre for Diffraction Data, 12 Campus Boulevard, Newtown Square, PA 19073-3273, U.S.A.

D.A. Porter, K.E. Easterling: Phase Transformations in Metals and Alloys (Chapman & Hall, London, UK, 2nd edition 1992) pp. 198–200

Y.C. Ha, H.J. Sohn, G.J. Jeong, C.K. Lee, K.I. Rhee: J. Appl. Electrochem. 30, 315 (2000)

Author information

Authors and Affiliations

Corresponding author

Additional information

PACS

81.05.Hd; 81.20.Ka; 61.46.+w

Rights and permissions

About this article

Cite this article

Zhao, X., Ji, X., Zhang, Y. et al. Hydrothermal synthesis and microstructure investigation of nanostructured bismuth telluride powder. Appl. Phys. A 80, 1567–1571 (2005). https://doi.org/10.1007/s00339-004-2956-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-004-2956-8