Abstract

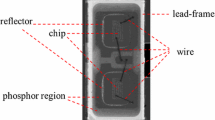

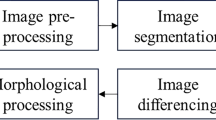

Amid diversification, high performance, high integration, and low-cost development in consumer electronic products, the conventional system on board function integration model is giving way to system on chip (SoC). Layout of solder balls under ball grid array (BGA) is getting irregular as system in package (SiP) is integrating multi-chip module and couple of active and passive components along with more complex circuit design. Due to the shortening life cycles of consumer electronic products and frequent new product launches, the incoming inspection operation of electronic components is getting tedious, let alone the component database updates required by mounter are also getting more frequent and time consuming due to increasingly complex and diversified components and soaring demands in characteristic measurement and identification difficulties. This study is aimed at building automated characteristic capture and analysis image processing model for BGA packages of irregular solder ball layout. It employs edge detection to get component body looks and dimensions by enhanced component edge characteristics. A image pre-processing model is used to identify consistency of individual solder ball characteristics with median filter, highlight image characteristics with binary conversion, remove noise with morphology, and connected component labeling to segment area covered by individual characteristic. In addition, a roundness and aspect ratio of the least rectangle-based solder ball characteristics identification method is proposed to determine number of, diameter of, and coordinates of center of border solder balls. The component characteristics acquired by the model comes in ± 3% difference against the actual one in terms of dimension. The model appears a good reference for system packaging operator in component database creation for the launch of new products in terms of reduced time for manual measurement and error as well as loss in mounter capacity. It also serves for electronic components incoming inspection to reduce inspection operation time and simplify the process.

Similar content being viewed by others

References

Yu SY, Kwon YM, Kim J, Jeong T, Choi S, Paik KW (2012) Studies on the thermal cycling reliability of BGA system-in-package (SiP) with an embedded die. IEEE Trans Compon Packag Manuf Technol 2(4):625–633

Zhang WW, Cong S, Wen ZJ, Liu Y, Wang YS, Tian YH (2017) Experiments and reliability research on bonding process of micron copper wire and nanometer gold layer. Int J Adv Manuf Technol 92:4073–4080

Canny J (1986) A computational approach to edge detection. IEEE Trans Pattern Anal Mach Intell 8(6):679–698

Yang J, Li B, Chen H (2011) Adaptive edge detection method for image polluted using Canny operator and Otsu threshold selection. Adv Mater Res 301-303:797–804

Museros L, Falomir Z, Velasco F, Gonzalez-Abril L, Martí I (2012) 2D qualitative shape matching applied to ceramic mosaic assembly. J Intell Manuf 23(5):1973–1983

Gonzalez C, Woods E (2002) Digital image processing 2/E. Prentice Hall, New Jersey

Vala HJ (2013) A review on Otsu image segmentation algorithm. Int J Adv Res Comput Eng Technol 2(2):387–389

Laghari MS (2015) Identification of faulty BGA solder joints in X-ray images. Int J Futur Comput Commun 4(2):122–125

Cai H, Liu Y (2014) Research on optical feature recognition technology of multiple micro-holes. Adv Mater Res 852:373–377

Singh P, Shree R (2016) A comparative study to noise models and image restoration techniques. Int J Comput Appl (0975–8887) 149(1):18–27

Nuanprasert S, Baba S, Suzuki T (2015) An efficient method of occluded solder ball segmentation for automated BGA void defect inspection using X-ray images, IECON 2015 - 41st Annual Conference of the IEEE Industrial Electronics Society, pp 3308–3313

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, CY., Wu, JY. & Huang, E. A digital image processing model for characteristics capture and analysis of irregular electronic components. Int J Adv Manuf Technol 102, 4309–4318 (2019). https://doi.org/10.1007/s00170-019-03451-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03451-5