Abstract

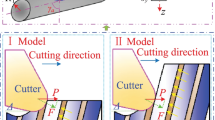

Despite increased applications of carbon fiber-reinforced plastic (CFRP) materials in many industries, such as aerospace, their machining is still a challenge due to their heterogeneity and anisotropic nature. In this research, a finite element model is used to investigate the cutting forces, chip formation mechanism, and machining damage present during the flat end milling of unidirectional CFRP. The material is modeled as an equivalent orthotropic homogeneous material, and Hashin’s theory is used to characterize failure in plane stress conditions. The friction coefficient between the tool and the composite material was assumed to be dependent on the carbon fiber orientation. A comparison of modeling and experimental results indicates that the model successfully predicts the cutting forces. The numerical model predictions of machining damage around the cutting area due to fiber compression damage and matrix cracking and the relation between damage extension and fiber orientation are confirmed through a comparison with SEM images of machined edges and surfaces.

Similar content being viewed by others

References

Davim JP (2015) Machinability of fibre-reinforced plastics, vol 4. Walter de Gruyter GmbH & Co KG, Berlin

Soldani X, Santiuste C, Muñoz-Sánchez A, Miguélez M (2011) Influence of tool geometry and numerical parameters when modeling orthogonal cutting of LFRP composites. Compos A: Appl Sci Manuf 42(9):1205–16

Dandekar CR, Shin YC (2012) Modeling of machining of composite materials: a review. Int J Mach Tool Manuf 57:102–21

Nayak D, Bhatnagar N, Mahajan P (2005) Machining studies of UD-FRP composites part 2: finite element analysis. Mach Sci Technol 9(4):503–28

Lasri L, Nouari M, El Mansori M (2009) Modelling of chip separation in machining unidirectional FRP composites by stiffness degradation concept. Compos Sci Technol 69(5):684–92

Santiuste C, Soldani X, Miguélez MH (2010) Machining FEM model of long fiber composites for aeronautical components. Compos Struct 92(3):691–8

Mkaddem A, Demirci I, El Mansori M (2008) A micro–macro combined approach using FEM for modelling of machining of FRP composites: cutting forces analysis. Compos Sci Technol 68(15):3123–7

Mkaddem A, El Mansori M (2009) Finite element analysis when machining UGF-reinforced PMCs plates: chip formation, crack propagation and induced-damage. Mater Des 30(8):3295–302

Santiuste C, Olmedo A, Soldani X, Miguélez H (2012) Delamination prediction in orthogonal machining of carbon long fiber-reinforced polymer composites. J Reinf Plast Compos 31(13):875–85

Isbilir O, Ghassemieh E (2013) Three-dimensional numerical modelling of drilling of carbon fiber-reinforced plastic composites. Journal of Composite Materials:0021998313484947

Ghafarizadeh S, Lebrun G, Chatelain J-F (2015) Experimental investigation of the cutting temperature and surface quality during milling of unidirectional carbon fiber reinforced plastic. Journal of Composite Materials:0021998315587131

ASTM (2009) D6641/D6641M-09: Standard test method for compressive properties of polymer matrix composite materials using a combined loading compression (CLC) test fixture. West Conshohocken, PA

ASTM (2012) D5379/D5379M: Standard test method for shear properties of composite materials by the V-notched beam method. West Conshohocken, PA

ASTM (2014) D3039/D3039M: Standard test method for tensile properties of polymer matrix composite materials. West Conshohocken, PA

ASTM (2008) D 792–08. Standard test methods for density and specific gravity (relative density) of plastics by displacement. West Conshohocken, PA

Ghafarizadeh S, Chatelain J-F, Lebrun G (2014) Effect of cutting tool lead angle on machining forces and surface finish of CFRP laminates. Science and Engineering of Composite Materials

Özel T, Altan T (2000) Process simulation using finite element method—prediction of cutting forces, tool stresses and temperatures in high-speed flat end milling. Int J Mach Tool Manuf 40(5):713–38

Li C, Lai X, Li H, Ni J (2007) Modeling of three-dimensional cutting forces in micro-end-milling. J Micromech Microeng 17(4):671

Ramulu M, Faridnia M, Garbini J, Jorgensen J (1991) Machining of graphite/epoxy composite materials with polycrystalline diamond (PCD) tools. J Eng Mater Technol 113(4):430–6

Arola D, Ramulu M (1997) Orthogonal cutting of fiber-reinforced composites: a finite element analysis. Int J Mech Sci 39(5):597–613

Ramesh M, Seetharamu K, Ganesan N, Sivakumar M (1998) Analysis of machining of FRPs using FEM. Int J Mach Tool Manuf 38(12):1531–49

Wang X, Zhang L (2003) An experimental investigation into the orthogonal cutting of unidirectional fibre reinforced plastics. Int J Mach Tool Manuf 43(10):1015–22

Hibbitt D, Karlsson B, Sorensen P (2012) Abaqus 6.12 documentation and user manual. Dassault Systèmes Simulia Corp.

Rao GVG, Mahajan P, Bhatnagar N (2007) Machining of UD-GFRP composites chip formation mechanism. Compos Sci Technol 67(11):2271–81

Rao GVG, Mahajan P, Bhatnagar N (2007) Micro-mechanical modeling of machining of FRP composites—cutting force analysis. Compos Sci Technol 67(3):579–93

Rentsch R, Pecat O, Brinksmeier E (2011) Macro and micro process modeling of the cutting of carbon fiber reinforced plastics using FEM. Procedia engineering 10:1823–8

Arola D, Sultan M, Ramulu M (2002) Finite element modeling of edge trimming fiber reinforced plastics. J Manuf Sci Eng 124(1):32–41

Schön J (2004) Coefficient of friction and wear of a carbon fiber epoxy matrix composite. Wear 257(3):395–407

Hashin Z (1980) Failure criteria for unidirectional fiber composites. J Appl Mech 47(2):329–34

Hashin Z, Rotem A (1973) A fatigue failure criterion for fiber reinforced materials. J Compos Mater 7(4):448–64

Lapczyk I, Hurtado JA (2007) Progressive damage modeling in fiber-reinforced materials. Compos A: Appl Sci Manuf 38(11):2333–41

Dieter GE, Bacon D (1986) Mechanical metallurgy, vol 3. McGraw-Hill New York

Shi Y, Swait T, Soutis C (2012) Modelling damage evolution in composite laminates subjected to low velocity impact. Compos Struct 94(9):2902–13

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghafarizadeh, S., Chatelain, JF. & Lebrun, G. Finite element analysis of surface milling of carbon fiber-reinforced composites. Int J Adv Manuf Technol 87, 399–409 (2016). https://doi.org/10.1007/s00170-016-8482-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8482-y