Abstract

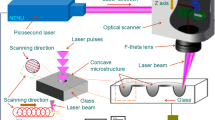

A hybrid of micro-lens array and freeform surface produces a novel micro-optic and micro-photovoltaic behaviors, but it is difficult to control both micro-form and macro-form accuracies in micro-machining of brittle photovoltaic glass. Hence, a ductile micro-grinding is proposed to replicate the precision-trued diamond wheel V-tip on macro-freeform glass substrate of solar cell. The objective is to understand the formation mechanism of accurate micro-lens array on freeform glass surface for photovoltaic application. First, the micro-optic properties of freeform micro-lens array were analyzed with regard to micro- and macro-shapes. Second, the precision and mirror micro-grinding along with the form errors of freeform micro-lens array was observed on the base of the transfer from brittle-mode removal to ductile-mode removal. Finally, the photovoltaic properties were experimentally measured. It is shown that the freeform micro-lens array increases luminous flux by 53.8–54.5 % compared with the plane and micro-lens array. The micro-form accuracy and the micro-structure mirror are dominated by micro-meter-scale diamond wheel V-tip with accurate wheel V-tip profile and integrated micro-grains protrusion, respectively. The novel measuring model of freeform micro-lens array may be used to evaluate and control the curved micro-form accuracy. The freeform micro-lens array contributes to the improvement of photovoltaic performance in scattered light illumination.

Similar content being viewed by others

References

Kanamori Y, Kikuta H, Hane K (2000) Broadband antireflection gratings for glass substrates fabricated by fast atom beam etching. Jpn J Appl Phys 39(7B):L735–L737

Tvingstedt K, Zilio SD, Inganas O, Tormen M (2008) Trapping light with micro lenses in thin film organic photovoltaic cells. Opt Express 16(26):21608–21615

Kataoka I (1998) Super smooth polishing technology for aspheric mirror finishes. J Jpn Soc Precis Eng 64:983–986

Xie J, Lu YX (2011) Study on axial-feed mirror finish grinding of hard and brittle materials in relation to micrometer-scale grain protrusion parameters. Int J Mach Tools Manuf 51(1):84–93

Muhammad Arif, Mustafizur Rahman, Wong Yoke San. An experimental study on the machining characteristics in ductile-mode milling of BK-7 glass. Int J Adv Manuf Technol, Vol. 60, No. pp. 487–495, 2012

Xie J, Zhuo YW, Tan TW (2010) Experimental study on fabrication and evaluation of micro pyramid-structured silicon surface using a V-tip of diamond grinding wheel. Precis Eng 35(1):173–182

Guo B, Zhao Q (2015) Mechanical truing of V-shape diamond wheels for micro-structured surface grinding. Int J Adv Manuf Technol 78(5):1067–1073

Chen EG, Wu RM, Guo TL (2014) Design a freeform microlens array module for any arbitrary-shape collimated beam shaping and color mixing. Opt Commun 321(15):78–85

Chen Y, Yi AY, Yao DG, Klocke F, Pongs G (2008) A reflow process for glass microlens array fabrication by use of precision compression molding. J Micromech Microeng 18(5):055022

Deng ZF, Chen F, Yang Q, Liu HW, Bian H, Du GQ, Hu Y, Si JH, Meng XW, Hou X (2012) A facile method to fabricate close-packed concave microlens array on cylindrical glass. J Micromech Microeng 22(11):115026

Peng Y, Jiang T, Ehmann KF (2014) Research on single-point diamond fly-grooving of brittle materials. Int J Adv Manuf Technol 75(9):1577–1586

Suzuki H, Okada M, Yamagata Y, Morita S, Higuchi T (2012) Precision grinding of structured ceramic molds by diamond wheel trued with alloy metal. CIRP Annals Manuf Technol 61(1):283–286

Xie J, Zhou RM, Xu J, Zhong YG (2010) Form-truing error compensation of diamond grinding wheel in CNC envelope grinding of free-form surface. Int J Adv Manuf Technol 48(9):905–912

Xie J, Li Q, Sun JX, Li YH (2015) Study on ductile-mode mirror grinding of SiC ceramic freeform surface using an elliptical torus-shaped diamond wheel. J Mater Process Technol 222(8):422–433

Sun CM, Zhao F, Zhang Z (2014) Modeling and simulation of space object optical scattering characteristics using TracePro. Acta Photonica Sinica 43(11):1122003–5

Xie J, Wu K, Cheng J, Li P, Zheng J (2015) The micro-optic photovoltaic behavior of solar cell along with microlens curved glass substrate. Energy Convers Manag 96(5):315–321

Xie J, Xie HF, Liu XR, Tan TW (2012) Dry micro-grooving on Si wafer using a coarse diamond grinding. Int J Mach Tools Manuf 61:1–8

Xie J, Li YH, Yang LF (2015) Study on 5-axial milling on microstructured freeform surface using the macro-ball cutter patterned with micro-cutting-edge array. CIRP Annals Manuf Technol 64:101–104

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Xie, J., Guo, R.B. et al. Precision and mirror micro-grinding of micro-lens array on macro-freeform glass substrate for micro-photovoltaic performances. Int J Adv Manuf Technol 86, 87–96 (2016). https://doi.org/10.1007/s00170-015-8105-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8105-z