Abstract

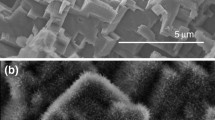

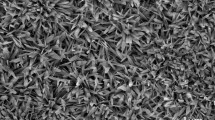

The superamphiphobic-functionalized CuO microflowers/Cu(OH)2 nanorod arrays hierarchical structure was prepared on the bamboo surface as a rough coating via a facile alkali assistant surface oxidation technique. Thereafter, the long- hydrophobic groups were grafted onto the bamboo to obtain superamphiphobic surfaces, which were super-repellent for water and hexadecane. The morphologies, microstructures, crystal structure, chemical compositions and states, as well as the hydrophobicity of the films on the bamboo substrates were analyzed by means of scanning electron microscopy (SEM), X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS) and water contact angle measurement. Additionally, the coating showed excellent environmental stability and high conductivity. It is expected that the work might expand the application of the superamphiphobic bamboo products.

Similar content being viewed by others

References

Boden PJ (1972) ‘Corrosion and corrosion control’. J Electrochem Soc 119:327C

Burnett PJ, Rickerby DS (1987) The mechanical properties of wear-resistant coatings: I: modelling of hardness behaviour. Thin Solid Films 148:41–50

Chen X, Kong L, Dong D, Yang G, Yu L, Chen J, Zhang P (2009a) Synthesis and characterization of superhydrophobic functionalized Cu(OH)2 nanotube arrays on copper foil. Appl Surf Sci 255:4015–4019. https://doi.org/10.1016/j.apsusc.2008.10.104

Chen XH, Kong LH, Dong D, Yang GB, Yu LG, Chen JM, Zhang PY (2009b) Fabrication of functionalized copper compound hierarchical structure with bionic superhydrophobic properties. J Phys Chem C 113:5396–5401. https://doi.org/10.1021/jp809616d

Cumings J, Zettl A (2000) Low-friction nanoscale linear bearing realized from multiwall. Carbon Nanotubes Sci 289:602–604

Deng X, Mammen L, Butt HJ, Vollmer D (2012) Candle soot as a template for a transparent robust. Superamphiphobic Coating Sci 335:67–70. https://doi.org/10.1126/science.1207115

Gao L, Xiao S, Gan W, Zhan X, Li J (2015) Durable superamphiphobic wood surfaces from Cu2O film modified with fluorinated alkyl silane. RSC Adv 5:98203–98208. https://doi.org/10.1039/c5ra19433d

Jin C, Li J, Han S, Wang J, Sun Q (2014) A durable, superhydrophobic, superoleophobic and corrosion-resistant coating with rose-like ZnO nanoflowers on a bamboo surface. Appl Surf Sci 320:322–327

Jin C, Li J, Han S, Wang J, Yao Q, Sun Q (2015) Silver mirror reaction as an approach to construct a durable, robust superhydrophobic surface of bamboo timber with high conductivity. J Alloys Compd 635:300–306. https://doi.org/10.1016/j.jallcom.2015.02.047

Kelly PJ, Arnell RD (1999) Magnetron sputtering: a review of recent developments and applications. Vacuum 56:159–172

Li J, Sun Q, Han S, Wang J, Wang Z, Jin C (2015) Reversibly light-switchable wettability between superhydrophobicity and superhydrophilicity of hybrid ZnO/bamboo surfaces via alternation of UV irradiation and dark storage. Prog Org Coat 87:155–160. https://doi.org/10.1016/j.porgcoat.2015.05.028

Liu K, Jiang L (2011) Metallic surfaces with special wettability. Nanoscale 3:825–838. https://doi.org/10.1039/c0nr00642d

Liu QS, Tong Z, Peng W, Liang G (2010) Preparation and characterization of activated carbon from bamboo by microwave-induced phosphoric acid activation. Ind Crops Prod 31:233–238

Liu F, Wang S, Zhang M, Ma M, Wang C, Li J (2013) Improvement of mechanical robustness of the superhydrophobic wood surface by coating PVA/SiO2 composite polymer. Appl Surf Sci 280:686–692. https://doi.org/10.1016/j.apsusc.2013.05.043

Liu X et al (2016) Sensitive room temperature photoluminescence-based sensing of H2S with novel CuO–ZnO nanorods. ACS Appl Mater Interfaces 8:16379–16385. https://doi.org/10.1021/acsami.6b02455

Meng HF, Wang ST, Xi JM, Tang ZY, Jiang L (2008) Facile means of preparing superamphiphobic surfaces on common engineering metals. J Phys Chem C 112:11454–11458. https://doi.org/10.1021/jp803027w

Mukherjee SK, Joshi L, Barhai PK (2011) A comparative study of nanocrystalline Cu film deposited using anodic vacuum arc and dc magnetron sputtering. Surf Coat Technol 205:4582–4595. https://doi.org/10.1016/j.surfcoat.2011.03.119

Nishimoto S, Bhushan B (2013) Bioinspired self-cleaning surfaces with superhydrophobicity, superoleophobicity, and superhydrophilicity. RSC Adv 3:671–690. https://doi.org/10.1039/c2ra21260a

Nishino T, Meguro M, Nakamae K, Matsushita M, Ueda Y (1999) The lowest surface free energy based on-CF3 alignment. Langmuir 15:4321–4323. https://doi.org/10.1021/la981727s

Ogwu AA, Bouquerel E, Ademosu O, Moh S, Crossan E, Placido F (2005) An investigation of the surface energy and optical transmittance of copper oxide thin films prepared by reactive magnetron sputtering. Acta Mater 53:5151–5159. https://doi.org/10.1016/j.actamat.2005.07.035

Tanvir NB, Yurchenko O, Wilbertz C, Urban G (2016) Investigation of CO2 reaction with copper oxide nanoparticles for room temperature gas sensing. J Mater Chem A 4:5294–5302. https://doi.org/10.1039/c5ta09089j

Teisala H, Geyer F, Haapanen J, Juuti P, Makela JM, Vollmer D, Butt HJ (2018) Ultrafast processing of hierarchical nanotexture for a transparent superamphiphobic coating with extremely low roll-off angle and high impalement. Pressure Adv Mater 30:e1706529. https://doi.org/10.1002/adma.201706529

Tuominen M et al (2016) Superamphiphobic overhang structured coating on a biobased material. Appl Surf Sci 389:135–143. https://doi.org/10.1016/j.apsusc.2016.05.095

Wang WZ, Varghese OK, Ruan CM, Paulose M, Grimes CA (2003) Synthesis of CuO and Cu2O crystalline nanowires using Cu(OH)(2) nanowire templates. J Mater Res 18:2756–2759. https://doi.org/10.1557/Jmr.2003.0384

Wang C et al (2014) One-step synthesis of unique silica particles for the fabrication of bionic and stably superhydrophobic coatings on wood surface. Adv Powder Technol 25:530–535. https://doi.org/10.1016/j.apt.2013.08.007

Xi J, Feng L, Jiang L (2008) A general approach for fabrication of superhydrophobic and superamphiphobic surfaces. Appl Phys Lett 92:053102. https://doi.org/10.1063/1.2839403

Xie QD, Xu J, Feng L, Jiang L, Tang WH, Luo XD, Han CC (2004) Facile creation of a super-amphiphobic coating surface with bionic microstructure. Adv Mater 16:302-. https://doi.org/10.1002/adma.200306281

Xu G, Wang L, Liu J, Wu J (2013) FTIR and XPS analysis of the changes in bamboo chemical structure decayed by white-rot and brown-rot fungi. Appl Surf Sci 280:799–805. https://doi.org/10.1016/j.apsusc.2013.05.065

Yang FC, Guo J, Liu MM, Yu S, Yan NB, Li J, Guo ZG (2015) Design and understanding of a high-performance gas sensing material based on copper oxide nanowires exfoliated from a copper mesh substrate. J Mater Chem A 3:20477–20481. https://doi.org/10.1039/c5ta06806a

Yao Q, Wang C, Fan B, Wang H, Sun Q, Jin C, Zhang H (2016) One-step solvothermal deposition of ZnO nanorod arrays on a wood surface for robust superamphiphobic performance and superior ultraviolet resistance. Sci Rep 6:35505. https://doi.org/10.1038/srep35505

Zalba B, Marín JMa, Cabeza LF, Mehling H (2003) Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl Therm Eng 23:251–283

Zhang W, Wen X, Yang S (2003a) Controlled reactions on a copper surface: synthesis and characterization of nanostructured copper compound films. Inorg Chem:5005–5014 https://doi.org/10.1021/ic0344214

Zhang WX, Wen XG, Yang SH, Berta Y, Wang ZL (2003b) Single-crystalline scroll-type nanotube arrays of copper hydroxide synthesized at room temperature. Adv Mater 15:822-. https://doi.org/10.1002/adma.200304840

Zhu X, Zhang Z, Xu X, Men X, Yang J, Zhou X, Xue Q (2012) Facile fabrication of a superamphiphobic surface on the copper substrate. J Colloid Interface Sci 367:443–449. https://doi.org/10.1016/j.jcis.2011.10.008

Zhu H et al (2016) Wood-derived materials for green electronics, biological devices, and energy. Appl Chem Rev 116:9305–9374. https://doi.org/10.1021/acs.chemrev.6b00225

Acknowledgements

This research was supported by The National Natural Science Foundation of China (31470584), Overseas Expertise Introduction Project for Discipline Innovation, 111 Project (No. B08016).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bao, W., Jia, Z., Cai, L. et al. Fabrication of a superamphiphobic surface on the bamboo substrate. Eur. J. Wood Prod. 76, 1595–1603 (2018). https://doi.org/10.1007/s00107-018-1349-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1349-1