Abstract

In inventory control and production planning one is tempted to use one of two strategies: produce all demand to stock or produce all demand to order. The disadvantages are well-known. In the ‘make everything to order’ case (MTO) the response times may become quite long if the load is high, in the ‘make everything to stock’ case (MTS) one gets an enormous inventory if the number of different products is large.

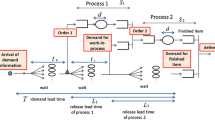

In this paper we study two simple models which combine MTO and MTS, and investigate the effect of combining MTO and MTS on the production lead times.

Zusammenfassung

In Lagerhaltung und Produktionsplanung werden überwiegend zwei alternative Strategien betrachtet: Produktion auf Bestellung oder auf Vorrat. Die Nachteile sind bekannt. Die erste Strategie kann zu sehr langen Durchlaufzeiten führen, die zweite zu hohen Beständen, insbesondere bei großer Produktanzahl. In dieser Arbeit werden zwei Modelle betrachtet, in denen die beiden Betrachtungsweisen kombiniert werden.

Similar content being viewed by others

References

Adan IJBF, van Doorn EA, Resing JAC, Scheinhardt, WRW (1996) A queueing system with two different service speeds. Memorandum COSOR 96-12, Department of Mathematics and Computing Science, Eindhoven University of Technology

Buzacott JA, Shanthikumar JG (1993) Stochastic models of manufacturing systems. Prentice Hall, New York

Carr AS, Güllü AR, Jackson PL, Muckstadt JA (1993) An exact analysis of a production-inventory strategy for industrial suppliers. Working paper, School of Operations Research and Industrial Engineering, Cornell University, Ithaca, NY

Coddington EA, Levinson N (1955) Theory of ordinary differential equations. McGraw-Hill, London

Federgruen A, Katalan Z (1994) Make-to-stock or make-to-order: that is the question; novel answers to an ancient debate. Working paper, Graduate School of Business, Columbia University, New York

Kleinrock L (1975) Queueing systems, Vol. I. Theory. Wiley, New York

Neuts MF (1981) Matrix-geometric solutions in stochastic models. Johns Hopkins University Press, Baltimore

Sox CR, Thomas LJ, McClain JO (1994) Jellybeans: Sorting capacity to improve service. Working paper, Department of Industrial Engineering, Auburn University, Alabama

Williams TM (1984) Special products and uncertainty in production/inventory systems. EJOR15: 46–54

Wolff RW (1982) Poisson arrivals see time averages. Opns. Res.30: 223–231

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Adan, I.J.B.F., van der Wal, J. Combining make to order and make to stock. OR Spektrum 20, 73–81 (1998). https://doi.org/10.1007/BF01539854

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01539854