Abstract

A simple and inexpensive capillary zone electrophoresis (CZE) with UV detection method was used to determine salicylic acid (SA) and six structural analogs (benzoic acid, 3-hydroxybenzoic acid, 4-hydroxybenzoic acid, acetylsalicylic acid, methyl salicylate, and jasmonic acid). All of the compounds were successfully separated within a migration period of 6 min, with a high number of theoretical plates (>37,000, calculated using the width at the base of the SA peak), in 20.0 mmol L-1 Na2HPO4/H3BO3 buffer (pH 9.0) containing 2.0% methanol and 2.0% acetonitrile. The regression line for SA was linear over the range 0.5–200 µmol L-1. Both the intra- and inter-day precisions of the migration time (relative standard deviations, RSDs, 0.6% and 4.7%, respectively) and peak area (RSDs 0.9% and 7.3%, respectively) were acceptable. The proposed method was used to determine the SA concentrations in tobacco leaves ( Nicotiana tabacum L.) from the Xanthi-nc ( NN genotype) and the Nt-NahG mutant strains that had been irradiated with UV (254 nm) for 20 min and the ones that had not been irradiated. Rapid separation (<6 min), good reproducibilities (RSDs < 11.9%), and good recoveries (94.7–118%) were obtained in the tobacco leaf analyses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

I. Introduction

Salicylic acid (2-hydroxybenzoic acid; SA) has been shown to play an important role in several physiological processes in plants, including heat production, flowering, and germination [1, 2]. The role of SA in pathogen resistance has been studied extensively in the last two decades [3, 4]. These studies have demonstrated that the accumulation of SA is related to the full expression of resistance to some pathogens, leading to alterations in mitochondrial function and changes in gene expression. In addition, immune responses, such as systemic acquired resistance and age-related resistance, have been found to be controlled by SA levels [5–7]. SA accumulation can also contribute to the hypersensitive response (HR), which may involve programmed cell death through the infection of a few cells [8, 9]. It is necessary, therefore, to quantify SA concentrations when studying plant immunity [10].

A fluorescence polarization immunoassay can be used to determine SA [11], but this assay is cross-reactive with SA metabolites, such as gentisic acid, and is insensitive to salicylamine, salicyluric acid, and SA conjugates [12]. SA and its metabolites can be analyzed individually by assays using high-performance liquid chromatography [13–17]. However, because of the complex biological matrices being analyzed, such assays require time-consuming sample preparation, and often require gradient elution, increasing the analysis time. It is also tissue-, time-, and labor-intensive to use methods involving gas chromatography-mass spectrometry and liquid chromatography-mass spectrometry. Capillary electrophoresis (CE) is an alternative to liquid and gas chromatographic methods, which offers advantages in terms of speed, simple sample preparation, separation efficiency, low column costs, and decreased sample and solvent consumption. CE methods have been used to separate and quantify phenolics in several plant species [18–22]. For example, a rapid CE method using solid phase extraction has been developed and validated for the analysis of five phenolic acids in tobacco [19]. The optimal buffer for this method was 25.0 mmol L-1 sodium borate (pH 9.3), and a separation voltage of + 25 kV was applied over a 48.5 cm capillary (40 cm to the detector window), which gave baseline separation of five phenolic acids in 7 min. However, the pretreatment process was complicated and labor intensive. The phenolic acids were extracted from the tobacco tissue in a Soxhlet extractor for 4 h, with the solvent heated to 80 °C, and the extract was purified using a solid phase extraction process. To avoid the need for a time-consuming and tedious preparation procedure, micellar electrokinetic capillary chromatography has been used to separate five benzoic acid compounds within 18 min [20]. The best conditions were obtained using a 20.0 mmol L-1 borax and 30.0 mmol L-1 sodium dodecyl sulfate (SDS) buffer (pH 9.8) containing 2.0 mmol L-1 β-cyclodextrin and 4% (v/v) methanol. This method allowed the analytes to be satisfactorily separated and determined quickly, but the amount of β-cyclodextrin and SDS used needed to be optimized because of complicated interactions between the analytes and the electrolyte. There has recently been a report of microemulsion electrokinetic capillary chromatography being used to quantify six plant hormones, all of which were separated within 10 min using a running buffer (pH 9.2) containing 10 mmol L-1 borate buffer, 1.0% (w/w) ethyl acetate, 0.6% (w/w) SDS, and 1.2% (w/w) 1-butanol [18]. The sensitivity of this method was improved using an online concentration method, but the amounts of ethyl acetate, SDS, and 1-butanol used in the microemulsion process needed to be optimized.

Here, we present a rapid capillary zone electrophoresis (CZE) method for analyzing SA in infected tobacco leaf tissues by using a simple extraction method. The effects of the separation voltage, sample injection volume, buffer composition and pH, and methanol and acetonitrile additives on the separation efficiency achieved for SA using the proposed CZE/UV method were evaluated. Using the optimum conditions, the regression line for SA was linear over the range 0.50–200 µmol L-1 (R = 0.9997). The limit of detection (LOD) was 0.21 µmol L-1 at a signal-to-noise (S/N) ratio of 3. Finally, NN genotype and Nt-NahG mutant tobacco leaves, with and without the presence of HR (elicited by exposure to UV irradiation), were analyzed for SA using the CZE/UV method. The results demonstrate that the CZE/UV method is a very flexible, reliable, and effective way of evaluating the homogeneity of and qualitatively determining the concentrations of SA in tobacco leaves.

II. Chemicals and methods

A. Chemicals

Acetylsalicylic acid (AA), methyl salicylate (MeSA), SA, methanol, ethanol, boric acid, sodium tetraborate, hydrochloric acid, sodium hydroxide, sodium phosphate, and phosphoric acid were obtained from Sigma-Aldrich (St. Louis, MO, USA). Tris(Base) and acetonitrile were obtained from J.T. Baker (Center Valley, PA, USA). 3-Hydroxybenzoic acid (3-HBA), benzoic acid (BA), jasmonic acid (JA), and 4-hydroxybenzoic acid (4-HBA) were obtained from Alfa Aesar (Heysham, UK). All chemicals were of analytical grade. The chemicals were diluted to give the desired final concentrations in ultrapure water (Millipore, Billerica, MA, USA). All buffer solutions were prepared in ultrapure water and then passed through a filter with 0.45 μm pores.

B. Apparatus

A high-voltage power supply (Gamma High Voltage Research, Ormond Beach, FL, USA) was used to drive the electrophoresis. For safety reasons, the high voltage end of the separation system was housed in a Plexiglas box. The CE system was coupled to a variable wavelength UV detector (SAPPHIRE 600; ECOM, Prague, Czech Republic). Data acquisition and processing were accomplished using a PC equipped with a Peak-ABC chromatography data handling system (Shanghai Qianpu Software Company Ltd., Shanghai, China).

C. Capillary Conditioning

Bare fused-silica capillaries (Polymicro Technologies, Phoenix, AZ, USA) with a 75 µm I.D. and a 365 µm O.D. were used to separate the phenolics. Before use, new capillaries were flushed with 0.5 mol L-1 NaOH for 30 min, rinsed extensively with water, and finally conditioned for 10 min with the buffer solution to be used for electrophoresis. The capillaries were 50 cm long, and the detection window was 10 cm from the outlet end. When not in use, the capillaries were stored in buffer to prevent buffer crystallization.

D. Tobacco Sample Extraction

The procedure for extracting SA was based on methods described previously [23]. Tobacco (Nicotiana tabacum L.) leaves from Xanthi-nc (NN genotype) and Nt-NahG mutant strains, with and without the presence of HR (elicited by UV irradiation at 254 nm for 20 min), were collected and frozen in liquid nitrogen. Prior to extraction, the plant material was ground in liquid nitrogen using a mortar and pestle. Each 0.25 g sample for analysis was further homogenized in liquid nitrogen and transferred to a 1.5 mL Eppendorf tube. An aliquot (0.5 mL) of 100% methanol was added to the homogenate, and when appropriate, as indicated in the text, a known amount of pure SA was added. The mixture was mixed by vortexing it for 1 min, and then sonicated for 5 min and centrifuged in a bench centrifuge for 10 min at the maximum speed. The supernatant was transferred to a 2 mL Eppendorf tube. The pellet was resuspended in 0.5 mL 100% methanol and the sonication and centrifugation steps were repeated. The supernatants were combined and centrifuged again, and then the solvent was evaporated using a SpeedVac concentrator at a high drying speed. Trichloroacetic acid (10%, 500 µL) was then added to the residue, and the solution was mixed by vortexing it. Partitioning the solution with 500 µL of a 1:1 (v/v) mixture of ethyl acetate and cyclohexane resulted in an upper organic solvent phase containing the free SA and a lower aqueous phase containing other compounds. This partitioning procedure was carried out twice. The upper layers, containing the free SA, were combined and evaporated to dryness using a SpeedVac concentrator at a medium drying speed. Finally, 20.0 mmol L-1 Na2HPO4/H3BO3 buffer (pH 9.0) was added to the residue, and the solution (i.e., the leaf extract) was mixed by vortexing it.

E. Determination of SA by CZE

The performance of the separation technique was tested under different conditions (buffer composition, concentration, and pH). A sample was injected into the capillary at the anode end, which was elevated 20 cm above the cathode end, by hydrodynamic injection over 25 s. A potential of + 16.0 kV, resulting in a current of 140 µA, was applied to bring about separation. UV detection was performed at 205 nm. The capillary was rinsed between runs with water and then the buffer used for the separation.

III. Results and discussion

A. Optimization of the CZE Method

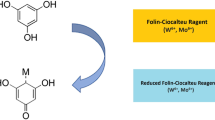

To propose a specific and accurate way of analyzing tobacco leaves containing SA using CZE, it is essential to find the best experimental conditions to separate the analytes from each other. The optimization process was performed using a synthetic mixture of SA and compounds with similar structures (BA, 3-HBA, 4-HBA, AA, MeSA, and JA) (Fig. 1). The parameters that were optimized, consecutively, were the buffer composition and concentration, the pH, the additives (methanol and acetonitrile), and other electrophoretic parameters (separation voltage and sample injection time).

The buffer composition, pH, and concentration significantly affect the separation performance because they influence the electro-osmotic flow (EOF) and the current produced in the capillary. Different buffer compositions were tested (Fig. 2), and sodium phosphate/boric acid produced the best results in terms of selectivity, reproducibility, baseline, and current. The buffer pH plays an important role in the selectivity of CE, especially for closely related compounds, because it affects both the overall charge in the solute and the EOF. The pKa values of the analytes we tested were 3.0 for SA, 4.2 for BA, 4.1 for 3-HBA, 4.6 for 4-HBA, 3.5 for AA, 9.8 for MeSA, and 4.5 for JA. The effect of the buffer pH was, therefore, investigated within the range 8.0–10.0 at a fixed buffer concentration, adjusted using 1 mol L-1 boric acid. The best resolution and selectivity was found at pH 9.0 (Fig. 3A), so this was selected as the optimum pH for separating SA. The buffer concentration can influence separation using CZE in several ways. A high buffer concentration can minimize solute adsorption to the capillary wall, but may produce considerable heat because of the Joule effect. Lowering the buffer concentration, on the other hand, can increase the EOF, resulting in a shorter analytical time. Keeping other parameters (pH 9.0, the buffer composition, run voltage, and injection time) constant, the buffer concentration was varied between 5.0 and 40.0 mmol L-1 (Fig. 3B). Both migration time and current increased with the buffer concentration. The resolution also increased as the buffer concentration was increased, but no appreciable improvement was observed at buffer concentrations above 20.0 mmol L-1. Baseline separation was obtained using a 20.0 mmol L-1 sodium phosphate/boric acid buffer solution at pH 9.0.

Separation of the analytes using different buffer systems. (a) Sodium tetraborate/boric acid buffer, (b) sodium tetraborate/phosphoric acid buffer, (c) sodium phosphate/boric acid buffer, (d) sodium phosphate buffer, and (e) Tris-HCl buffer. All buffer solutions had concentrations of 20.0 mmol L-1 and pH 9.0. Standards: a: BA (10 µmol L-1); b: SA (10 µmol L-1); c: 3-HBA (10 µmol L-1); d: 4-HBA (10 µmol L-1); e: AA (10 µmol L-1); f: MeSA (10 µmol L-1); g: JA (100 µmol L-1)

Separation of the analytes in phosphate/boric acid buffer solution at (A) different pH values (a: 8.0; b: 9.0; and c: 10.0) and (B) different concentrations (a: 5.0; b: 10.0; c: 20.0; and d: 40.0 mmol L-1). Capillary: 50 cm full length, 40 cm effective length, 75 µm I.D., 365 µm O.D.; hydrodynamic injection: 10 s for a 20 cm height; 14.0 kV running voltage; detection by UV absorbance at 205 nm

Organic solvents (methanol and acetonitrile) used as additives usually produce a solute-stacking effect, which allows a large volume of sample to be injected into the capillary, improving the sensitivity. Organic solvents also significantly affect the separation performance because of their influences on the EOF and the current produced in the capillary. First, the effect of the methanol concentration was investigated within the range 0–5.0%, using fixed buffer conditions (Fig. 4A). The migration time and resolution increased as the methanol concentration was increased. The number of plates also increased as the methanol concentration was increased, but no appreciable improvements were observed at methanol concentrations above 2.0%. A methanol concentration of 2.0% was, therefore, selected for the next experiments. The effect of the acetonitrile concentration was investigated within the range 0%– 10.0% (Fig. 4B). The migration time and resolution increased with the acetonitrile concentration. However, higher acetonitrile concentrations caused baseline disturbances because of the Joule heat produced. An acetonitrile concentration of 2.0% was, therefore, selected.

Separation of the analytes in 20.0 mmol L-1 phosphate/boric acid buffer solution (pH 9.0) with different additives. (A) Methanol (a: 0; b: 1.0; c: 2.0; and d: 5.0%) and (B) acetonitrile (a: 0; b: 2.0; c: 5.0; and d: 10.0%). The other conditions were the same as those shown in Figure 3.

In principle, ideal separation is generally obtained by applying as high a voltage as possible because the number of plates in CE is proportional to the applied voltage. However, this benefit is limited by the heat generated because of the Joule effect during the electrophoretic process. This heat results in the broadening of the peaks and a decrease in the separation efficiency. In this study, the best separation was achieved using a voltage of 16.0 kV (Fig. 5A). The current increased as the voltage was increased, leading to disturbances in the baseline. Therefore, a voltage of 16.0 kV was selected as the optimum. The sample injection time has been shown to be proportional to the sample volume introduced into the capillary, which can be optimized to give analyte peaks large enough to quantify. The effect of the loading time on the peak area was investigated by hydrodynamically injecting the standards (100 µmol L-1 of JA and 10 µmol L-1 of each of the other compounds) with injection times of 5, 10, 15, 20, 25, 30, and 35 s. The resulting peak area for each compound was plotted as a function of injection time (Fig. 5B). A linear relationship was found between the injection time and peak area for all compounds up to an injection time of 25 s, so 25 s was chosen as the optimum injection time.

Separation of the analytes in 20.0 mmol L-1 phosphate/boric acid buffer solution (pH 9.0) in the presence of 2.0% methanol and 2.0% acetonitrile at (A) different voltages (a: 10.0; b: 14.0; c: 16.0; and d: 20.0 kV). (B) Plots of the peak areas obtained using different injection times (5, 10, 15, 20, 25, 30, and 35 s) for each analyte. The other conditions were the same as those shown in Figure 3.

B. Method Validation

The linearity and detection limits for the standards using the optimal experimental conditions are listed in Table I. The calibration plots were drawn as the peak area against the concentration, and the concentrations were different for different standards. Five point calibration curves were produced, and three replicate injections were performed for each standard at each concentration. The calibration equations were calculated using the least-squares linear regression method. The detection limit was defined as the analyte concentration that gave a peak area with a signal to noise ratio of 3.

Replicate injections of a 2 µmol L-1 standard containing all of the analytes were carried out to determine the reproducibility (intra-day precision) of the method. In all cases, the precision was better than 0.6% for the migration time and 0.9% for the peak area. Good peak area precision was achieved without adding an internal standard. Intermediate precision (inter-day precision) was evaluated over three days by performing three injections each day. The intermediate precision was better than 4.7% for the migration time and 7.3% for the peak area.

C. Determination of SA in Tobacco Leaves

Once the optimal conditions for separation and quantitation were established, the CE method was used to determine SA in tobacco leaves extract matrix. A 25 µL aliquot of a diluted solution of each tobacco extract was collected and divided into five 5 µL aliquots, which were used to determine the accuracy of the method. The proposed method was used to analyze the five aliquots, and the average of the SA concentrations that were determined was taken as the original value. Known quantities of SA were then added to other aliquots, and the SA concentrations in them were determined following the recommended procedure (Table II). The recoveries of the SA spiked into the tobacco leaf extracts were in the range 94.7%–118%.

With the expectation that the CZE/UV method would have great potential for use in the analysis of SA in plant samples, a standard addition method was applied to determine the concentration of SA in NN genotype and Nt-NahG mutant tobacco leaves with and without UV irradiation. The SA concentrations found in the NN genotype tobacco leaves were 4.12 ± 0.28 µmol L-1 before UV irradiation and 8.06 ± 0.38 µmol L-1 after UV irradiation (Fig. 6A). These concentrations are clearly different, which is consistent with the results of previous studies of the induction of SA biosynthesis by UV irradiation [23]. However, the SA concentrations in the Nt-NahG mutant tobacco leaves were almost the same before UV irradiation (4.28 ± 0.11 µmol L-1, n = 3) and after UV irradiation (4.41 ± 0.18 µmol L-1, n = 3) (Fig. 6B). An F-test (the F value was 19 at the 95% confidence level) revealed that there was no significant difference between the precision achieved for the irradiated and unirradiated samples (the F value calculated at the 95% confidence level for the samples was 2.68). A t-test (the t-test value was 2.776 at the 95% confidence level) showed that the SA concentrations in the leaves before and after UV irradiation were not significantly different (the t value calculated at the 95% confidence level for the samples was 1.067). There was a lack of difference between the SA concentrations in the Nt-NahG mutant tobacco leaves before and after UV irradiation because this strain expresses the NahG transgene, which is generated using the binary plasmid containing salicylate hydroxylase (NahG). Transgenic Nt-NahG mutant tobacco leaves do not, therefore, accumulate SA after UV irradiation at 254 nm for 20 min. Our results suggest that the CZE/UV method has the potential to be a quantitative assay for SA in tobacco leaves.

Electropherograms of (A) NN genotype and (B) Nt-NahG mutant tobacco leaves with and without UV irradiation (*: SA). The other conditions were the same as those shown in Figure 5.

IV. Conclusions

The use of CZE for separating SA and six structural analogs was investigated. All of the analytes were determined with a high degree of efficiency in a short period (<6 min). This method may be considered for the routine analysis of large numbers of samples. The method is simple, rapid, and economical, and can be used to determine SA in NN genotype and Nt-NahG mutant tobacco leaves, with and without the presence of HR caused by UV irradiation.

Acknowledgments

This study was supported by the National Science Council of Taiwan under contract NSC 101-2113-M-018-001-MY2 and a research grant from the National Changhua University of Education for new scholars. The authors thank Enago (www.enago.tw) for correcting the English language.

References

G. K. Sahu, Salicylic Acid : Role in Plant Physiology and Stress Tolerance. In Molecular Stress Physiology of Plants, Springer: 2013, pp 217–239.

M. Yusuf, S. Hayat, M. N. Alyemeni, Q. Fariduddin and A. Ahmad, Salicylic Acid: Physiological Roles in Plants. In SALICYLIC ACID, Springer: 2013, pp 15–30.

A. M. Murphy, S. Chivasa, D. P. Singh and J. P. Carr, “Salicylic acid-induced resistance to viruses and other pathogens: a parting of the ways?,” Trends Plant Sci., vol. 4 (4), pp. 155–160, 1999.

I. Raskin, “Role of salicylic acid in plants,” Annu. Rev. Plant Biol., vol. 43 (1), pp. 439–463, 1992.

M. Frias, N. Brito and C. Gonzalez, “The Botrytis cinerea cerato-platanin BcSpl1 is a potent inducer of systemic acquired resistance (SAR) in tobacco and generates a wave of salicylic acid expanding from the site of application,” Mol. Plant Pathol., vol. 14 (2), pp. 191–196, 2013.

Y. Shibata, K. Kawakita and D. Takemoto, “Age-Related Resistance of Nicotiana benthamiana Against Hemibiotrophic Pathogen Phytophthora infestans Requires Both Ethylene- and Salicylic Acid-Mediated Signaling Pathways,” Mol. Plant-Microbe Interact., vol. 23 (9), pp. 1130–1142, 2010.

S. Sharma and B. Sohal, “Effect of salicylic acid on biochemical (Disease resistant) compounds in Brassica juncea RLM619,” Appl. Biol. Res., vol. 15 (1), pp. 78–82, 2013.

J. Jovel, M. Walker and H. Sanfacon, “Salicylic Acid-Dependent Restriction of Tomato ringspot virus Spread in Tobacco Is Accompanied by a Hypersensitive Response, Local RNA Silencing, and Moderate Systemic Resistance,” Mol. Plant-Microbe Interact., vol. 24 (6), pp. 706–718, 2011.

F. R. Rossi, A. Garriz, M. Marina, F. M. Romero, M. E. Gonzalez, I. G. Collado and F. L. Pieckenstain, “The Sesquiterpene Botrydial Produced by Botrytis cinerea Induces the Hypersensitive Response on Plant Tissues and Its Action Is Modulated by Salicylic Acid and Jasmonic Acid Signaling,” Mol. Plant-Microbe Interact., vol. 24 (8), pp. 888–896, 2011.

C. T. DeFraia, E. A. Schmelz and Z. Mou, “A rapid biosensor-based method for quantification of free and glucose-conjugated salicylic acid,” Plant Methods, vol. 4 (1), pp. 2–8, 2008.

M. Gutierrez, A. Gomez-Hens and D. Perez-Bendito, “Immunoassay methods based on fluorescence polarization,” Talanta, vol. 36 (12), pp. 1187–1201, 1989.

M. Koel and P. Nebinger, “Specificity data of the salicylate assay by fluorescent polarization immunoassay,” J. Anal. Toxicol., vol. 13 (6), pp. 358–360, 1989.

X. Zhang, Z. X. Zhang, L. T. Wang, Q. Liu, X. L. Zhang, S. Q. Dong and L. Zhao, “Chromatographic Evaluation of Octadecyl-Bonded SiO2/SiO2-Based Stationary Phase for Reversed-Phase High Performance Liquid Chromatography,” J. Inorg. Organomet. Polym. Mater., vol. 23 (6), pp. 1445–1450, 2013.

J. Pauwels, W. D'Autry, L. Van den Bossche, C. Dewever, M. Forier, S. Vandenwaeyenberg, K. Wolfs, J. Hoogmartens, A. Van Schepdael and E. Adams, “Optimization and validation of liquid chromatography and headspace-gas chromatography based methods for the quantitative determination of capsaicinoids, salicylic acid, glycol monosalicylate, methyl salicylate, ethyl salicylate, camphor and 1-menthol in a topical formulation,” J. Pharm. Biomed. Anal., vol. 60 pp. 51–58, 2012.

X. F. Guo, Y. Zhou, F. Q. Tu, X. J. Xiong, H. Wang and H. S. Zhang, “Determination of phytohormones in plant samples based on the precolumn fluorescent derivatization with 1,3,5,7-tetramethyl-8-aminozide-difluoroboradiaza-s-indacene by HPLC for routine use,” J. Sep. Sci., vol. 34 (7), pp. 789–795, 2011.

Y. L. Wu and B. Hu, “Simultaneous determination of several phytohormones in natural coconut juice by hollow fiber-based liquid-liquid-liquid microextraction-high performance liquid chromatography,” J. Chromatogr. A, vol. 1216 (45), pp. 7657–7663, 2009.

E. A. Schmelz, J. Engelberth, H. T. Alborn, P. O'Donnell, M. Sammons, H. Toshima and J. H. Tumlinson, “Simultaneous analysis of phytohormones, phytotoxins, and volatile organic compounds in plants,” Proc. Natl. Acad. Sci. U. S. A., vol. 100 (18), pp. 10552–10557, 2003.

Z. B. Chen, Z. A. Lin, L. Zhang, Y. Cai and L. Zhang, “Analysis of plant hormones by microemulsion electrokinetic capillary chromatography coupled with on-line large volume sample stacking,” Analyst, vol. 137 (7), pp. 1723–1729, 2012.

F. W. Xie, A. A. Yu, Y. A. Cheng, R. B. Qi, Q. Y. Li, H. M. Liu and S. S. Zhang, “Rapid Separation and Determination of Five Phenolic Acids in Tobacco by CE,” Chromatographia, vol. 72 (11-12), pp. 1207–1212, 2010.

S. Y. Gao, H. Li, L. Wang and L. N. Yang, “Simultaneous Separation and Determination of Benzoic Acid Compounds in the Plant Medicine by High Performance Capillary Electrophoresis,” J. Chin. Chem. Soc., vol. 57 (6B), pp. 1374–1380, 2010.

J. Hernandez-Borges, G. Gonzalez-Hernandez, T. Borges-Miquel and M. A. Rodriguez-Delgado, “Determination of antioxidants in edible grain derivatives from the Canary Islands by capillary electrophoresis,” Food Chem., vol. 91 (1), pp. 105–111, 2005.

A. D. Shapiro and A. T. Gutsche, “Capillary electrophoresis-based profiling and quantitation of total salicylic acid and related phenolics for analysis of early signaling in Arabidopsis disease resistance,” Anal. Biochem., vol. 320 (2), pp. 223–233, 2003.

P.-J. Tseng, C.-Y. Wang, Z.-Y. Huang, Y.-Y. Zhuang, S.-F. Fu and Y.-W. Lin, “A facile colorimetric assay for determination of salicylic acid in tobacco leaves using titanium dioxide nanoparticles,” Anal. Methods, vol. 6 (6), pp. 1759–1765, 2014.

Author information

Authors and Affiliations

Additional information

* Corresponding e-mail: linyejerry@cc.ncue.edu.tw (Y.W.L.)

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, WT., Wang, CI., Fu, SF. et al. Analysis of Salicylic Acid in Tobacco Leaves Using Capillary Zone Electrophoresis with UV Detection. GSTF J Chem Sci 1, 1 (2014). https://doi.org/10.7603/s40837-014-0001-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.7603/s40837-014-0001-9