Abstract

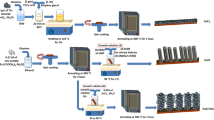

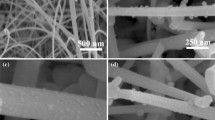

This study reports the effects of NiO nanoparticle (NP) size on the sensing performance of NiO NP-decorated SnO2 nanorods (NRs). NiO NP-decorated SnO2 NRs were synthesized using a two-step process: 1) thermal evaporation of tin powders in an oxidizing atmosphere based on the vapor-liquid-solid growth mechanism and 2) solvothermal decoration of SnO2 NRs with NiO NPs. X-ray diffraction and transmission electron microscopy analyses revealed that both the SnO2 NRs and the NiO NPs were polycrystalline. Scanning electron microscopy images showed that the diameters of the NRs ranged from 100 to 200 nm and that those of the small and the large NiO NPs ranged from 20 to 30 nm and from 80 to 180 nm, respectively. The small NiO NP-decorated SnO2 NRs showed stronger response to NO2 than did the large NiO NP-decorated SnO2 NRs over the concentration range of 0.5–100 ppm. Decoration of SnO2 NRs with small NiO NPs resulted in enhanced sensing performance whereas decoration of SnO2 NRs with large NiO NPs deteriorated the sensing performance. The superior NO2 gas sensing performance of the small NiO NP-decorated SnO2 NR sensor as compared to that of the large NiO NP-decorated SnO2 NR sensor was attributed to a higher ratio of n-SnO2 to p-NiO and a higher number of p-n heterojunctions for the same volume of NiO in the former than in the latter. In addition, the small NiO NP-decorated SnO2 NR sensors showed selectivity toward NO2 against other competing gases such as SO2, CO2, CO, H2, C7H8 and C6H6.

Similar content being viewed by others

References

Q. Wan and T. Wang, Chem. Commun. 1, 3841 (2005).

X. Xue et al., J. Phys. Chem. C 112, 12157 (2008).

A. Kolmakov et al., Nano Lett. 5, 667 (2005).

Q. Kuang et al., J. Phys. Chem. C 112, 11539 (2008).

H. Kim et al., Sens. Actuators B 161, 594 (2012).

D. Wang et al., J. Phys. Chem. C 112, 13499 (2008).

S. Park, S. An, Y. Mun and C. Lee, ACS Appl. Mater. Interfaces 5, 4285 (2013).

J. Tamaki et al., Sens. Actuators B 49, 121 (1998).

L. Lin et al., Nanoscale 5, 588 (2013).

C. Jin, S. Park, H. Kim and C. Lee, Sens. Actuators B 161, 223 (2012).

C. Cao et al., Sens. Actuators B 156, 114 (2011).

S. W. Fan, A. K. Srivastava and V. P. Dravid, Appl. Phys. Lett. 95, 142106 (2009).

S. Park et al., ACS Appl. Mater. Interfaces 4, 3650 (2012).

W. Wen, J. M. Wu and Y. D. Wang, Sens. Actuators B 184, 78 (2013).

X. Cai et al., Sens. Actuators B 198, 402 (2014).

H. Sato, T. Minami, S. Takata and T. Yamada, Thin Solid Films 236, 27 (1993).

I. Bouessay, A. Rougier, B. Beaudoin and J. B. Leriche, Appl. Surf. Sci. 186, 490 (2005).

I. Bouessay et al., Electrochim. Acta 50, 3737 (2005).

A. M. Turky, Appl. Catal. A 247, 83 (2003).

H. Kumagai, M. Matsumoto, K. Toyoda and M. Obara, J. Mater. Sci. Lett. 15, 1081 (1996).

I. Hotovy et al., Sens. Actuators B 103, 300 (2004).

I. Hotovy et al., Thin Solid Films 515, 658 (2006).

A. Aslani and M. Fallahi, Appl. Surf. Sci. 257, 4056 (2011).

P. Rai et al, Nanoscale 6, 8292 (2014).

S. H. Kim, S. H. Park, S. Y. Park and C. Lee, Sens. Actuators B 209, 180 (2015).

N. Barsan and U. Weimar, J. Electroceramics 7, 143 (2001).

N. D. Hoa and S. A. El-Safty, Chem. Eur. J. 17, 12896 (2011).

S-W. Choi et al., J. Mater. Chem. C 1, 2834 (2013).

A. Kar et al., Nanotechnology 22, 285709 (2011).

A. Mirzaei et al., Ceram. Int. 42, 6136 (2016).

Acknowledgments

This study was supported by the 2020 Basic Science Research Program, the research project title of which is Development of capsule-type sensors for detecting gases in the mute, through the National Research Foundation of Korea (NRF) funded by the Ministry of Education.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, K., Jeong, G., Hyun, S.K. et al. Effects of Particle Size on the NO2 Gas Sensing Properties of NiO Nanoparticle-Decorated SnO2 Nanorods. J. Korean Phys. Soc. 77, 482–488 (2020). https://doi.org/10.3938/jkps.77.482

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.77.482