Abstract

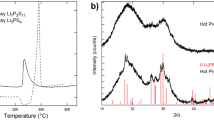

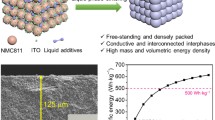

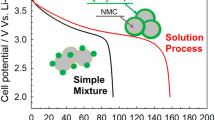

A Composite cathode without polymer binder was prepared by a one-step sintering method employing spark plasma sintering (SPS) of laminated LiCoO2 and Li3BO3 pellets. The amorphous Li3BO3 solid electrolyte melted during the sintering process. For better characterization of the composite cathode, a liquid electrolyte was used in the battery test. However, the active material was mainly in the all-solid-state environment. The specific capacity of the composite cathode was found to be dependent on its thickness. The 0.2 mm thick composite cathode showed a high specific discharge capacity of 99 mAh g −1 at 0.5 C rate, excellent cycling performance over 10 cycles, and good rate capability of about 93.2 mAh g −1 with 94% retention capacity. In addition, the composite cathode showed an initial discharge capacity of 0.25 mAh g −1. The discharge capacity after 3 cycles under the all-solid-state condition was 0.22 mAh g −1. The SEM and TEM results showed that the melted Li3BO3 solid electrolyte synthesized by the SPS process produced Li+ ion transport pathways, which reduced the grain boundary resistance. Hence, this composite cathode consisting of LiCoO2 as the cathode, amorphous Li3BO3 as the solid electrolyte, and MWCNT as the electric conductor is a promising material for all-solid-state batteries and bulk-type hybrid solid-state batteries.

Similar content being viewed by others

References

X. M. Liu, Z. D. Huang, S. W. Oh, B. Zhang, P. C. Ma, M. M. F. Yuen and J. K. Kim, Compos. Sci. Technol. 72, 121 (2012).

M. Tatsumisago, R. Takano, K. Tadanaga and A. Hayashi, J. Power Sources 270, 603 (2014).

K. Chen, Y. Shen, Y. Zhang, Y. Lin and C. W. Nan, J. Power Sources 249, 306 (2014).

I. Y. Kim, S. Y. Shin, J. H. Ko, K. S. Lee, S. P. Woo, D. K. Kim and Y. S. Yoon, J. Korean Ceram. Soc. 54, 9 (2017).

J. S. Kim, H. S. Kim and K. S. Kang, J. Korean Ceram. Soc. 55, 21 (2018).

K. Takada, Acta Mater. 61, 759 (2013).

J. B. Bates, N. J. Dudney, B. Neudecker and A. Ueda, Solid State Ionics 135, 33 (2000).

C. Julien, G. A. Nazri, J. P. Guesdon, A. Gorenstein, A. Khelfa and O. M. Hussain, Solid State Ionics 73, 319 (1994).

K. H. Kim, Y. Iriyama, K. Yamamoto, S. Kumazaki, T. Asaka, K. Tanabe, C. A. J. Fisher, T. Hirayama, R. Murugan and Z. Ogumi, J. Power Sources 196, 764 (2011).

B. Hung, X. Yao, Z. Huang, Y. Guan, Y. Kin and X. Xu, J. Power Source 284, 206 (2015).

M. Hung, T. Liu, Y. Deng, H. Geng, Y. Shen, Y. Lin and C. W. Nan, Solid State Ionic 204–205, 41 (2011).

M. Hara, H. Nakano, K. Dokko, S. Okuda, A. Kaeriyama and K. Kanamura, J. Power Sources 189, 485 (2009).

H. Zhang, X. Yu and P. V. Braun, Nature Nano. 6, 277 (2011).

R. Kali and A. Mukhopadhyay, J. Power Sources 247, 920 (2014).

H. Kitaura, A. Hayasho, T. Ohtomo, S. Hama and M. Tatsumisago, J. Mater. Chem. 21, 118 (2011).

S. Ohta, S. Komagata, J. Seki, T. Saeki, S. Morishita and T. Asaoka, J. Power Sources 238, 53 (2013).

L. Jinlian, W. Xianmaing, C. Shang, L. Jianben and H. Zeqiang, Bull. Mater. Sci. 36, 687 (2013).

N. Kuwata, J. Kawamura, K. Toribami, T. Hattori and N. Sata, Electrochem. Commun. 6, 417 (2004).

F. Croce, G. B. Appetecchi, L. Persi and B. Scrosati, Nature 394, 456 (1998).

T. Waldmann, M. Wilka, M. Kasper, M. Fleischhammer and M. W. Mehrens, J. Power Sources 262, 129 (2014).

E. D. Botto, C. Bourbon, S. Patoux, P. Rozier and M. Dolle, J. Power Sources 196, 2274 (2011).

Y. Wu, D. Pasero, E. E. McCabem, Y. Matsushima and A. R. West, Proc. R. Soc. A 465, 1829 (2009).

K. Tadanaga, R. Takano, T. Ichinose, S. Mori, A. Hayashi and M. Tatsumisago, Electrochem. Commun. 33, 51 (2013).

M. Kotobuki, Y. Suzuki, H. Munakata, K. Kanamura, Y. Sato, K. Yamamoto and T. Yoshida, J. Electrochem. Soc. 157, A493 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Woo, S.P., Lee, W. & Yoon, Y.S. Composite Cathode Material Using Spark Plasma Sintering for Bulk-Type Hybrid Solid-State Batteries. J. Korean Phys. Soc. 73, 1019–1024 (2018). https://doi.org/10.3938/jkps.73.1019

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.73.1019