Abstract

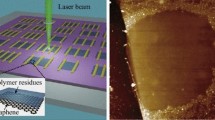

Graphene has been considered an ideal material for application in transparent lightweight wearable electronics due to its extraordinary mechanical, optical, and electrical properties originating from its ordered hexagonal carbon atomic lattice in a layer. Precise surface control is critical in maximizing its performance in electronic applications. Graphene grown by chemical vapor deposition is widely used but it produces polymeric residue following wet/chemical transfer process, which strongly affects its intrinsic electrical properties and limits the doping efficiency by adsorption. Here, we introduce a facile dry-cleaning method based on UV irradiation to eliminate the organic residues even after device fabrication. Through surface topography, Raman analysis, and electrical transport measurement characteristics, we confirm that the optimized UV treatment can recover the clean graphene surface and improve graphene-FET performance more effectively than thermal treatment. We propose our UV irradiation method as a systematically controllable and damage-free post process for application in large-area devices.

Similar content being viewed by others

References

Y. Dan, Y. Lu, N. J. Kybert, Z. Luo and A. T. C. Johnson, Nano. Lett. 9, 1472 (2009).

W. Yuan and G. Shi, J. Mater. Chem. A. 1, 10078 (2013).

J. W. Suk, A. Kitt, C. W. Magnuson, Y. Hao, S. Ahmed, J. An, A. K. Swan, B. B. Goldberg and R. S. Ruoff, ACS. Nano 5, 6916 (2011).

W. Choi, M. A. Shehzad, S. Park and Y. Seo, RSC. Adv. 7, 6943 (2017).

S. Ryu, L. Liu, S. Berciaud, Y. J. Yu, H. Liu, P. Kim, G. W. Flynn and L. E. Brus, Nano Lett. 10, 4944 (2010).

A. Prikle, J. Chan, A. Venugopal, D. Hinojos, C. W. Magnuson, S. McDonnell, L. Colombo, E. M. Vogel, R. S. Ruoff and R. M. Wallace, Appl. Phys. Lett. 99, 122108 (2011).

Z. Cheng, Q. Zhou, C. Wang, Q. Li, C. Wang and U. Fang, Nano Lett. 11, 767 (2011).

Y. Mulyana, M. Uenuma, Y. Ishikawa and Y. Uraoka, J. Phys. Chem. Lett. C 118, 27372 (2014).

H. V. Ngoc Y. Qian, S. K. Han and D. J. Kang, Sci. Rep. 6, 33096 (2016).

A. Das et al., Nat. Nanotech. 3, 210 (2008).

J. R. Vig, J. Vac. Sci. Technol. A 3, 1027 (1985).

S. Baunack and A. Zehe, Phys. Status solidi A-Appl. Mat. 115, 223 (1989).

W. Li, Y. Liang, D. Yu, L. Peng, K. P. Pernstich, T. Shen, A. R. HightWalker, G. Cheng, C. A. Hacker, C. A. Richter, Q. Li, D. J. Gundlach and X. Liang, Appl. Phys. Lett. 102, 183110 (2013).

C. W. Jang, J. H. Kim, J. M. Kim, D. H. Shin, S. Kim and S. H. Choi, Nanotechnology 24, 405301 (2013).

X. Li, W. Cai, J. An, S. Kim, J. Nah, D. Yang, R. Piner, A. Velamakanni, I. Jung, E. Tutuc, S. K. Banerjee, L. Colombo and R. S. Ruoff, Science 324, 1312 (2009).

H. H. Kim, S. K. Lee, S. G. Lee, E. H. Lee and K. Cho, Adv. Funct. Mater. 26, 2070 (2016).

G. H. Lee et al., Science 340, 1073 (2013).

P. Y. Huang et al., Nature 469, 389 (2011).

W. Wei, C. Yang, J. Mai, L. Yan, K. Zhao, H. Ning, S. Wu, J. Gao, X. Gao, G. Zhou, X. Lu and J. M. Liu, J. Mater. Chem. C 5, 10652 (2017).

S. K. Kwon and D. H. Kim, Trans. Electr. Electron. Mater. 17, 204 (2016).

J. H. Bong, O. Sul, A. Yoon, S. Y. Choi and B. J. Cho, Nanoscale 6, 8503 (2014).

Z. Xu, Z. Ao, D. Chu, A. Younis, C. M. Li and S. Li, Sci. Rep. 4, 6450 (2014).

F. Banhart, J. Kotakoski and A. V. Krasheninnikov, ACS Nano 5, 26 (2011).

X. Wang and H. Dai, Nat. Chem. 2, 661 (2010).

D. C. Kim, D. Y. Jeon, H. J. Chung, Y. S. Woo, J. K. Shin and S. Seo, Nanotechnology 20, 375703 (2009).

I. Childres, L. A Jauregui, J. Tian and Y. P Chen, New J. Phys. 13, 025008 (2011).

F. Schwierz, Nat. nanotechnol. 5, 487 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J.H., Haidari, M.M., Choi, J.S. et al. Facile Dry Surface Cleaning of Graphene by UV Treatment. J. Korean Phys. Soc. 72, 1045–1051 (2018). https://doi.org/10.3938/jkps.72.1045

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.72.1045