Abstract

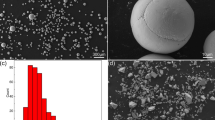

The spark plasma sintering (SPS) method is advantageous for sintering metallic powders due to its ability to produce a sample with fine microstructure without defects and pores even at lower temperature and within a shorter time than that produced by conventional sintering process. It is reported that a degassing treatment prior to sintering by using the SPS method was reported to be a critical step for removing particle-particle boundaries (PBs) effectively. In spite of much research on sintering processes for Mg alloys by using the SPS method, systematic studies on the effect of degassing parameters such as the degree of vacuum, degassing pressure and degassing time, on the microstructural changes and the mechanical properties are lacking. In this study, the microstructural evolution and the mechanical properties of monocrystalline Mg-6% Al alloys were investigated to determine the degassing parameters prior to sintering to remove PBs completely and to obtain a magnesium alloy having high strength and high ductility.

Similar content being viewed by others

References

H. E. Friedrich and B. L. Mordike, Magnesium technology (Springer, Berlin, 2006).

R. Zeng, W, Dietzel, F. Witte, N. Hort and C. Blawert, Adv. Biomater. 10, B3 (2008).

C. Di Mario et al., J. Interv. Cardiol. 17, 391 (2004).

N. Ogawa, M. Shimi and K. Osakada, Int. J. Mach. Tools Manuf. 42, 607 (2002).

G. W. Nieman, J. R. Weertman and R. W. Siegel, J. Mater. Res. 6, 1012 (1991).

M. Jain and T. Christman, Acta. Metall. Mater. 42, 1901 (1994).

J. W. Ahn, D. Y. Hwang, G. H. Kim and H. S. Kim, Korean J. Met. Mater. 49, 454 (2011).

M. H. Yoo, Metall. Trans. A 12, 409 (1981).

Y. Minamino, Y. Koizumi, N. Tsuji, N. Nirohata, K. Mizuuchi and Y. Ohkanda, Sci. Technol. Adv. Mater. 5, 133 (2004).

M. Cabibbo, C. Paternoster, R. Cecchini, A. Fabrizi, A. Molinari, S. Libardi and M. Zadra, Mater. Sci. Eng. A. 496, 121 (2008).

G. Straffelini, A. P. Nogueira, P. Muterlle and C. Menapace, Mater. Sci. Technol. 27, 10 (2011).

D. Chakravarty, S. Bysakhm, K. Muraleedharan, T. N. Rao and R. Sundaresan, J. Am. Ceram. Soc. 91, 203 (2008).

W. N. A. W. Muhammad, Z. Sajuri, Y. Mutoh and Y. Miyashita. J. Alloys Compd. 509, 6021 (2011).

J. W. Choi, H. C. Chul and K. S. Shin, Trends Metals Mater. Engineer. 22, 3 (2009).

Y. Kawamura, K. Hayashi, A. Inoue and T. Masumoto, Mater. Trans. 42, 1172 (2001).

J. K. Lee, T. S. Kim, H. J. Jeong and J. C. Bae, Mater. Sci. Forum. 534, 833 (2007).

T. S. Kim, H. J. Chae, J. K. Lee, H. G. Jung, Y. D. Kim and C. C. Bae, Mater. Sci. Forum 534, 793 (2007).

G. Xie, O. Ohashi, N. Yamaguchi and A. Wang, Metall. Mater. Trans. A 34, 2655 (2003).

K. R. Kim, B. J. Song, Y. S. Yang and H. S. Kim, Korean J. Met. Mater. 51, 585 (2013).

K. R. Kim, H. S. Kim, S. H. Kwon, J. of the Korean Physical Society, 65, 1669 (2014).

W. J. Kim, C. W. An, Y. S. Kim and S. I. Hong, Scripta Mater. 47, 39 (2002).

K. Kondoh, H. Fukuda, J. Umeda and H. Imai, Mater. Sci. Eng. A 527, 4103 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koo, S.M., Kim, K.R., Yang, Y.S. et al. Effect of degassing parameters on the microstructure and properties of nanocrystalline magnesium alloys in spark plasma sintering. Journal of the Korean Physical Society 69, 354–360 (2016). https://doi.org/10.3938/jkps.69.354

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.69.354