Abstract

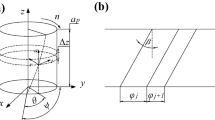

Means of decreasing the vibration in moderate- and high-speed cutting are considered, so as to improve the surface quality. End mills with damping elements are developed so as to control the tool rigidity.

Similar content being viewed by others

REFERENCES

Korotkikh, M.T., Ivanov, M.I., and Ivanova, N.S., Dynamic features of new machine tool systems and vibration damping, Informatizatsiya: Estestvozn.-Tekh.-Obraz/-Kul’t., 2000, no. 2, pp. 126–132.

Sharapin, I.A., Raschet kolebanii privoda. Vibroizolyatsiya (Calculation of Drive Vibrations. Vibration Isolation), St. Petersburg: St.-Peterb. Gos. Univ. Prom. Tekhnol. Dizaina, 2014.

Telegin, V.V. and Korobkov, S.A., Simulation models in the study of the dynamics of mechanical systems, Fundam. Issled., Tekh. Nauki, 2014, no. 12, pp. 25–30.

Bishop, R.E.D., Vibration, Cambridge: Cambridge Univ. Press, 1965.

Vulfson, I.I., Energy transfer in vibratory systems of drives with cyclic mechanisms, J. Mach. Manuf. Reliab., 2013, vol. 42, no. 4, pp. 261–268.

Medunetskii, V.M., Niteiskii, A.S., and Rasshchupkin, A.V., Development of a damping system to reduce vibration of the milling alignment, Omsk. Nauchn. Vestn., 2018, no. 1 (157), pp. 5–9.

Vul’fson, I.I., Influence of low-frequency oscillations on nonlinear dissipative forces. Applied problems of nonlinear theory of oscillations and waves, Izv. Vyssh. Uchebn. Zaved., Prikl. Nelineinaya Din., 2012, vol. 20, no. 4, pp. 51–65.

Kapitsa, P.L., Pendulum with vibrating suspension, Usp. Fiz. Nauk, 1951, vol. 44, no. 1, pp. 7–20.

Agapov, S.I., Scientific substantiation and implementation of ultrasonic technologies in the production of precision small-modular wheels, Cand. Sci. (Eng.) Dissertation, Volgograd, 2015.

Brzhozovskii, B.M., Khairov, D.A., and Yankin, I.N., Diagnostics of cutting of materials based on the analysis of nonrandom components of the oscillatory process, Fundam. Prikl. Probl. Tekhn. Tekhnol., 2012, nos. 2–4 (292), pp. 109–114.

Kuznetsov, S.F., Stability of the milling in the technical system of mobile equipment, Cand. Sci. (Eng.) Dissertation, Lipetsk, 2016.

Bolsunovskii, S.A., Vermel’, V.D., and Gubanov, G.A., Prevention of vibration in high speed milling, RITM: Remont. Innovatsii. Tekhnol. Modernizatsiya, 2012, no. 4 (72), pp. 24–26.

Astashev, V.K., Korendyasev, G.K., and Erofeev, V.I., Thermomechanical model of excitation of self-oscillations in metal cutting, Vestn. Nizhegorod. Univ. im. N.I. Lobachevskogo, 2013, no. 1 (3), pp. 29–35.

Levitskii, N.I., Kolebaniya v mekhanizmakh (Vibrations in Mechanisms), Moscow: Nauka, 1988.

Kryazhev, Yu.A., Gorin, E.Yu., and Yunin, A.A., Quality improvement of the machined surface during milling using the vibration-resistant construction of the end mill, Materialy XIII Vserossiiskoi nauchno-tekhnicheskoi konferentsii studentov, aspirantov i molodykh uchenykh (Proc. XIII All-Russ. Sci.-Tech. Conf. of Students, Post-Graduate Students, and Young Scientists), Barnaul: Altai. Gos. Tekh. Univ., 2016. http://edu.secna.ru/media/f/tehnology_mashin_tez_2016.pdf.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Kryazhev, Y.A., Gorin, E.Y. Vibration-Limited Composite Cutting Tool with Damping Elements. Russ. Engin. Res. 41, 1054–1059 (2021). https://doi.org/10.3103/S1068798X21110162

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21110162