Abstract—

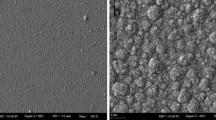

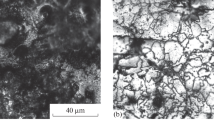

The article presents the results of surface modification of austenitic stainless steel by electrolyte-plasma nitriding under anodic and cathodic polarity of the product being treated. The morphology and surface roughness, phase composition, and microhardness of diffusion layers, as well as tribological and corrosion properties, were studied. The effect of physicochemical processes during anodic and cathodic treatments on the features of the formation of a modified surface and its operational properties is demonstrated. The anodic treatment increased the hardness of the nitrided layers up to 1150 HV, halved the surface roughness, improved the wear resistance by a factor of 166, and decreased the coefficient of friction by a factor of 1.6. The cathodic treatment increased the hardness only to 580 HV and improved the wear resistance by a factor of 13.6. Both treatments were shown to decrease pitting corrosion in a sodium chloride medium.

Similar content being viewed by others

REFERENCES

Sun, Y., Sliding wear behavior of surface mechanical attrition treated AISI 304 stainless steel, Tribol. Int., 2013, vol. 57, p. 67.

Mordyuk, B.N. and Prokopenko, G.I., Ultrasonic impact peening for the surface properties’ management, J. Sound Vib., 2007, vol. 308, nos. 3–5, p. 855.

Lee, H., Kim, D., Jung, J., et al., Influence of peening on corrosion properties of AISI 304 stainless steel, Corros. Sci., 2009, vol. 51, no. 12, p. 2826.

Baraz, V.R., Kartak, B.R., and Mineeva, O.N., Features of friction hardening of austenitic steel with an unstable γ-phase, Metalloved. Term. Obrab. Met., 2010, no. 10, p. 20.

Hajian, M., Abdollah-zadeh, A., Rezaei-Nejad, S.S., et al., Improvement in cavitation erosion resistance of AISI 316L stainless steel by friction stir processing, Appl. Surf. Sci., 2014, vol. 308, p. 184.

Makarov, A.V., Savrai, R.A., Pozdejeva, N.A., Smirnov S.V., et al., Effect of hardening friction treatment with hard-alloy indenter on microstructure, mechanical properties, and deformation and fracture features of constructional steel under static and cyclic tension, Surf. Coat. Technol., 2010, vol. 205, p. 841.

Kuznetsov, V.P., Makarov, A.V., Osintseva, A.L., et al., Hardening and improving the surface quality of parts made of austenitic stainless steel by diamond burnishing on a turning-milling center, Uprochn. Tekhnologii Pokryt., 2011, no. 11, p. 16.

Belkin, P.N., Kusmanov, S.A., Zhirov, A.V., et al., Anode plasma electrolytic saturation of titanium alloys with nitrogen and oxygen, J. Mat. Sci. Tech., 2016, vol. 32, p. 1027.

Kusmanov, S.A., Dyakov, I.G., Belkin, P.N., et al., Plasma electrolytic modification of the VT1-0 titanium alloy surface, J. Surf. Invest. X-ray Synchrotron Neutron Tech., 2015, vol. 9, p. 98.

Belkin, P.N., Borisov, A.M., and Kusmanov, S.A, Plasma electrolytic saturation of titanium and its alloys with light elements, J. Surf. Invest. X-ray Synchrotron Neutron Tech., 2016, vol. 10, p. 516.

Belkin, P.N. and Kusmanov, S.A., Plasma electrolytic nitriding of steels, J. Surf. Invest. X-ray Synchrotron Neutron Tech., 2017, vol. 11, p. 767.

Skakov, M.K. and Kurbanbekov, Sh.R., Investigation of corrosion resistance and phase composition of surface layers of 12Kh18N10T steel after plasma nitrocarburizing and nitriding, Vestn. Kazakh. Nats. Tekh. Univ., 2013, no. 4.

Hua, X.-Z., Zhou, L., Cui, X., et al., The effect of ammonia water on the microstructure and performance of plasma electrolytic saturation nitriding layer of 38CrMoAl steel, Phys. Proc., 2013, vol. 50, p. 304.

Kumruoglu, L.C. and Ozel, A., Plasma electrolytic saturation of 316L stainless steel in an aqueous electrolyte containing urea and ammonium nitrate, Mater. Technol., 2013, vol. 47, no. 3, p. 307.

Roy, A., Tewari, R.K., Sharma, R.C., and Sherhar, R., Feasibility study of aqueous electrolyte plasma nitriding, Surf. Eng., 2007, vol. 23, no. 4, p. 243.

Aliev, M.Kh., Sabour, A. and Taheri, P., Study of corrosion protection of different stainless steels by nanocrystalline plasma electrolysis, Prot. Met. Phys. Chem. Surf., 2008, vol. 44, no. 4, p. 402.

Andrei, V., Vlaicu, Gh., Fulger, M., et al., Chemical and structural modifications induced in structural materials by electrochemical process, Roman. Report. Phys., 2009, vol. 61, no. 1, p. 95.

Smirnov, A.A., Kusmanov, S.A., Kusmanova, I.A., and Belkin, P.N., Effect of electrolyte depletion on the characteristics of the anodic plasma electrolytic nitriding of a VT22 titanium alloy, Surf. Eng. Appl. Electrochem., 2017, vol. 53, p. 413.

Kusmanov, S.A., Tambovskiy, I.V., Silkin, S.A., et al., Anode plasma electrolytic borocarburising of alpha + beta-titanium alloy, Surf. Interfaces, 2020, vol. 21, p. 100717.

Kusmanov, S.A., Kusmanova, Y.V., Smirnov, A.A., and Belkin, P.N., Modification of steel surface by plasma electrolytic saturation with nitrogen and carbon, Mat. Chem. Phys., 2016, vol. 175, p. 164.

Tambovskiy, I., Mukhacheva, T., Gorokhov, I., et al., Features of cathodic plasma electrolytic nitrocarburizing of low-carbon steel in an aqueous electrolyte of ammonium nitrate and glycerin, Metals, 2022, vol. 12, p. 1773.

Kusmanov, S.A., Smirnov, A.A., Silkin, S.A., and Belkin, P.N., Increasing wear and corrosion resistance of low-alloy steel by anode plasma electrolytic nitriding, Surf. Coat. Technol., 2016, vol. 307, p. 1350.

Apelfeld, A., Borisov, A., Dyakov, I., Grigoriev, S., et al., Enhancement of medium-carbon steel corrosion and wear resistance by plasma electrolytic nitriding and polishing, Metals, 2021, vol. 11, p. 1599.

Funding

This work was supported by the Russian Science Foundation grant (project no. 18-79-10094) to Kostroma State University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by M. Baznat

About this article

Cite this article

Kusmanov, S.A., Tambovskii, I.V., Mukhacheva, T.L. et al. Electrolyte-Plasma Nitriding of Austenitic Stainless Steel under Cathodic and Anodic Polarity. Surf. Engin. Appl.Electrochem. 59, 582–589 (2023). https://doi.org/10.3103/S1068375523050101

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375523050101